As temperatures begin to rise, many homeowners struggle to keep their homes cool and comfortable. High energy bills, drafty doors and windows, and inefficient air conditioning systems can all contribute to a hot and uncomfortable living environment. Fortunately, there is a solution that can help keep your home cool and comfortable all summer long – Sing Core door panels.

As temperatures begin to rise, many homeowners struggle to keep their homes cool and comfortable. High energy bills, drafty doors and windows, and inefficient air conditioning systems can all contribute to a hot and uncomfortable living environment. Fortunately, there is a solution that can help keep your home cool and comfortable all summer long – Sing Core door panels.

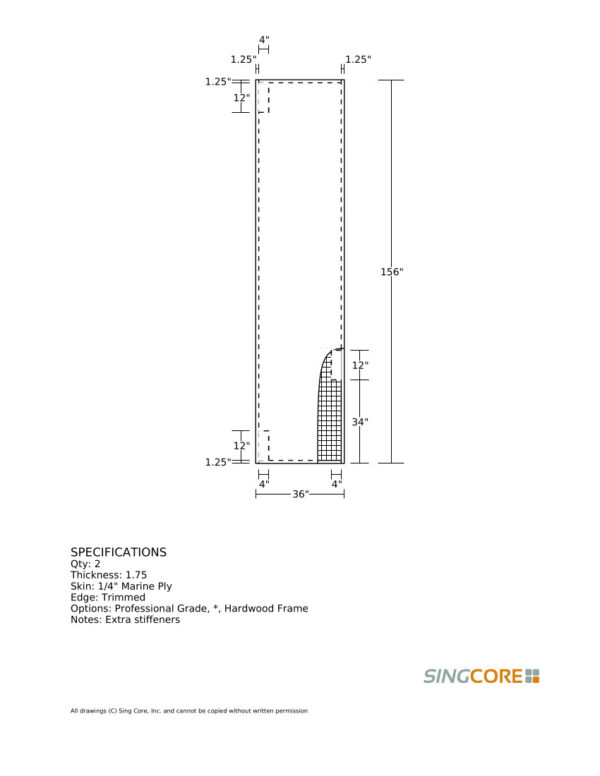

Sing Core panels are a revolutionary product that combines strength, durability, and insulation properties. These panels are made from a patented honeycomb core that is sandwiched between two layers of material, creating a lightweight and incredibly strong panel. But what makes Sing Core door panels truly unique is their insulation properties. The honeycomb core is made up of tons of small insulation pockets that trap air and provide exceptional temperature retention, helping to keep your home cool in the summer and warm in the winter.

So how can Sing Core door panels help improve your home and keep your house cool as temperatures rise? Here are a few ways:

Energy Efficiency

One of the main benefits of Sing Core door panels is their energy efficiency. Traditional doors are often made from materials that provide little to no insulation, allowing hot air to enter your home and cool air to escape. Sing Core panels, on the other hand, are highly insulated and can help to prevent air leakage, reducing the amount of energy needed to cool your home. This can lead to lower energy bills and a more comfortable living environment.

Customizable Options

Sing Core door panels are highly customizable, allowing you to choose from a variety of materials, finishes, and styles. This means that you can choose a panel that not only provides excellent insulation properties but also matches the style of your home. Whether you prefer the look of natural wood or the sleekness of aluminum, Sing Core panels can be customized to fit your needs. This also allows you to get a custom sized or fit door for your specific frame, providing insulation in a scenario that traditional methods may not be able to.

Durability

Sing Core panels are incredibly strong and durable, making them an excellent choice for exterior doors. They can withstand harsh weather conditions, including extreme temperatures, high winds, and heavy rain, without warping or failing. Our panels even come with a 50 Year Warp Free and Structural Guarantee, meaning you can trust them to provide long-lasting protection and insulation for your home.

Noise Reduction

In addition to their insulation properties, Sing Core panels also provide excellent noise reduction. The honeycomb core helps to absorb sound waves, reducing the amount of noise that enters your home. This can be especially beneficial if you live in a noisy neighborhood or near a busy street.

Easy Installation

Finally, Sing Core door panels are easy to install, making them a convenient and hassle-free solution for homeowners. They can be installed in many different ways to suit your needs, allowing for a quicker, easier, and better door.

In conclusion, Sing Core door panels are an innovative and effective solution for keeping your home cool and comfortable as temperatures rise. With their insulation properties, customizable options, durability, noise reduction, and easy installation, they are a smart investment for any homeowner looking to improve the energy efficiency and comfort of their home. Whether you’re looking to replace your exterior doors, update your interior doors, or improve the insulation of your home, Sing Core panels are a great choice.