Custom Door Skins by Sing Core

Custom Door Skins Build your Way. Strong. Light. Straight.

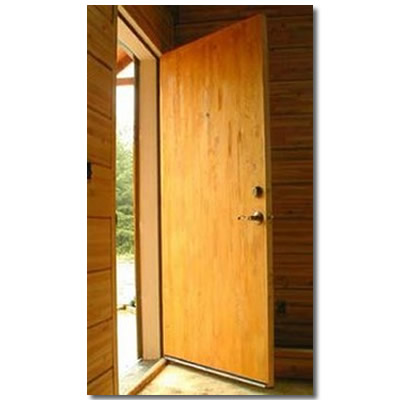

Custom Door Skins let you design any door you want. And with Sing Core inside, your door stays flat, strong, and light. Because of this, architects, millworks, and contractors trust our panels for projects of every size. And yes, you can choose almost any skin you want.

To get pricing, visit our Estimate Page. It is fast. And it is easy.

Why Choose Custom Door Skins?

Custom Door Skins change the way doors perform. First, the skin sets the look. Then, the Sing Core inside gives you strength. And finally, the door stays lightweight, even at huge sizes. With Sing Core, your doors resist warping, denting, and twisting better than anything else.

So, your door lasts longer. And your project stays on budget.

Get your Custom Door Quote FAST!!!

Get your custom door quote fast with our easy estimate page. First, choose your size. Then, choose your skin. After that, send your details. As a result, you get the best price for your project. So, visit our estimate page now and start your door today.

Custom Door Skin Options

Below are the most popular Custom Door Skins. Every option works with Sing Core panels. And every panel can be made in almost any size.

1. Paint Grade Door Skins

Paint Grade skins are the most affordable. They are simple. But they are strong. And they are light. Because of this, they are perfect for builders who want a clean, smooth look. You can prime and paint them in any color.

2. Wood Veneer Door Skins

Wood Veneer skins create a rich, natural look. They are ideal for staining. And they offer a high-end finish. Even better, they stay flat because Sing Core supports them from within. Choose from many veneer species.

3. Solid Wood Plank Door Skins

Solid Wood Plank skins give a warm, real-wood feel. Yet they cost far less than thick solid-wood doors. These planks create a premium appearance while staying light. And therefore, they are great for extra-wide or tall doors.

4. Metal Door Skins (Steel or Aluminum)

Metal skins make ultra-strong doors. They are available in many thicknesses. And they can meet high fire ratings. You can even design bullet-resistant doors. Because Sing Core reduces weight, these metal panels stay easy to handle.

5. Fiberglass Door Skins (FRP)

Fiberglass skins are very durable. They resist weather. They resist dents. And they work indoors or outdoors. They are also low-maintenance, which makes them ideal for high-traffic areas.

6. Ceramic Door Skins

Ceramic skins are perfect for fire-rated and high-heat doors. And, thanks to the impact-absorbing Sing Core, they resist cracking better than standard ceramic panels. These skins offer both protection and style.

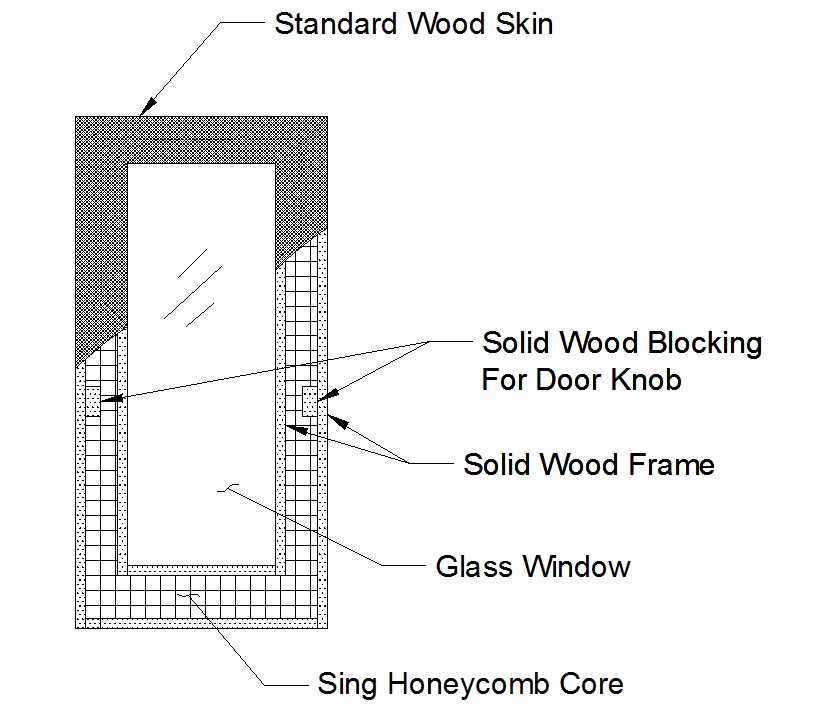

Why Custom Door Skins Work So Well with Sing Core

Every Custom Door Skin performs better with the Sing Core structure. The core is light. It is strong. It is stable. And as a result, your door stays straight for decades.

If the outer skin is ever damaged, you can repair it easily. The structure supports patching without sagging or distortion.

Door thickness ranges from 3/4 inch to no maximum thickness. Door sizes range from tiny cabinet doors to doors over 16 ft tall and 24 ft wide.

Door Types We Build

We use Custom Door Skins on four main structures:

-

Solid Doors

Best for doors up to 4 ft by 8 ft. Very strong. -

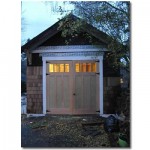

Barn-Style Multi-Panel Doors

Large doors joined with strips or trim. Simple and affordable. -

Oversize Paint-Grade Doors

Seamless construction using biscuit joints. Smooth. Stable. Ready for paint. -

Wood-Grain Veneer or Plank Doors

The look of fine wood. The stability of Sing Core.

How to Order Custom Door Skins

Ordering is simple. First, choose your Custom Door Skin. Then choose your size. After that, send your dimensions. And finally, get your quote.

Because custom work varies, we price every panel by size and quantity. So, for fast pricing, visit our Estimate Page now.

Ready to Design Your Door?

Sing Core makes Custom Door Skins for every project. And with our lightweight, high-precision core, your door stays strong and straight for years.

Click below to get your estimate today.

It’s so easy to use Sing Panels to make beautiful

It’s so easy to use Sing Panels to make beautiful