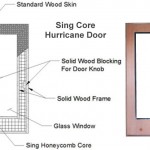

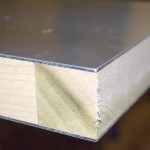

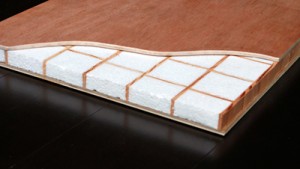

Sing High Precision Doors are a marked improvement in door development, design and implementation thanks to a newly invented Eco-friendly core material that is lightweight, insulated and stronger than steel pound for pound.

Sing High Precision Doors are a marked improvement in door development, design and implementation thanks to a newly invented Eco-friendly core material that is lightweight, insulated and stronger than steel pound for pound.

This new technology is revolutionizing the door industry especially in regards to large oversize doors. Architects, designers, mill works and door manufacturers all experience problems with doors that are larger than normal size.

Large doors present a variety of challenges in areas, like:

- choice of available materials

- lightweight doors are weak and tend to fail

heavy doors strain hardware and structure

heavy doors strain hardware and structure- increased regular maintenance

- failure due to warping

Sing High Precision Doors solve all these issues with an Eco-friendly insulated solution.

How high precision are Sing High Precision Doors?

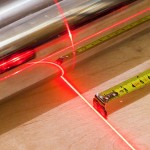

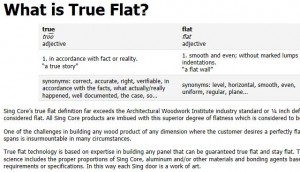

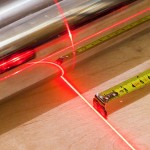

Sing High Precision doors are created with so much accuracy that the original door slabs are perfectly flat within .0006 inch accuracy.

After applying your desired composite materials and/or skin, your high precision door can be laser CNC machined for a perfectly flat surface, limited only by the accuracy of your CNC machine shop capabilities.

The Large Challenge

Certainly, you could use laser CNC cutting and engraving to machine nearly any door made of almost any commonly used door material for a flat result. The challenge comes from standing the door upright and expecting a degree of effective usefulness over time.

Why Large Doors Fail

Why Large Doors Fail

The effects of gravity, varying degrees of moisture and/or atmospheric change, and the natural limitations of the characteristics of the building materials that comprise the door all contribute to its failure. This causes dissatisfaction for the end user, who has invested a great deal of expense in the design, manufacture and installation of this specialty large door.

Door warping is the number one problem for oversized doors that are otherwise enjoyed by the most discriminating end users.

The Disappointment

No one wants to spend that kind of money on a door that is going to warp, bend, twist, delaminate or compromise the structure or hardware with normal recommended use.

Now, here’s the exciting part…

Sing High Precision Doors can be guaranteed not to warp, bend twist or otherwise fail for 50 years!

Imagine having a large door that can be installed that will not pave the way for repeated service calls over the life of the door.

Imagine having a large door that can be installed that will not pave the way for repeated service calls over the life of the door.

Take a look at some of our clients who trust us with those difficult door challenges because they are the most reputable high performers in the industry who only deliver the highest marks in terms of customer satisfaction, especially now that they can deliver a fail-free large door that will not cause frustration for their client’s or their service departments. See clients List.

Highest Precision in Doors

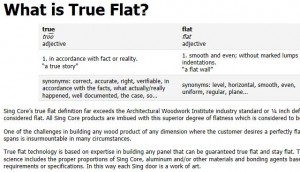

Click Image for True Flat

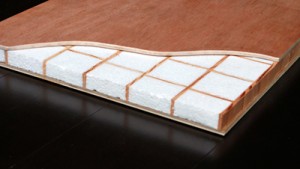

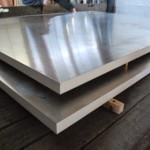

No other building material can be guaranteed to maintain a true flat surface and milled with laser precision for long-term maintenance-free performance for 50 years. This is why you can find the growing demand for the Sing solution from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

No other building material can be guaranteed to maintain a true flat surface and milled with laser precision for long-term maintenance-free performance for 50 years. This is why you can find the growing demand for the Sing solution from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

The high precision Sing solution is not just for doors; turned flat these very same Sing Panels can become floors, tables, counter tops, ceilings and roofs. Turned on their sides, these patented panels become walls, moveable partitions or virtually any other type of application.