Welcome to Sing Core’s Greatest Hits a compilation of our most requested Sing innovations that starts with your FREE CONSULTATION. Book your private show with Sing Core today and you’ll be breaking records and singing a new song while you dance all the way to the bank.

Hot Rolled Steel Doors

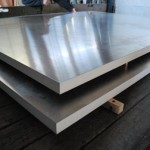

Sing Core brings an Eco-friendly approach to working with large spans of hot rolled steel with less weight and more strength than plain steel pound for pound, revolutionizing the steel fabrication process. In fact, we are best known for our large hot rolled steel metal doors and hot rolled steel wall panels.

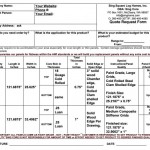

Our patented rolled steel panels feature custom metal fabrication uses high grade formaldehyde free adhesives instead of the more destructive welding process and your Sing Hot Rolled Steel Panel can host an exterior hot rolled sheet metal thickness of 16 gauge or more.

Sing hot rolled steel takes metal working into a whole new arena that is being embraced by steel companies making huge hot rolled steel products without having to use heavy steel framing.

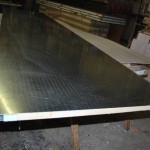

One of the primary functions of Sing hot rolled steel products is in the area of commercial steel entry doors. If you are new to metal manufacturing, you will find that raw hot rolled steel has a more primitive or industrial feel to it, it has a less smooth surface than cold rolled steel and requires finishing to avoid rust or oxidation. The unique appearance of hot rolled steel panels appeals to designers, architects, museums, art galleries and often used in steel wall art.

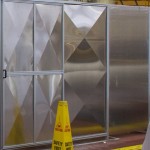

Especially if you’re considering utilizing hot rolled steel for your large doors, Sing Core can help to mitigate the damages caused by the heavy weight of hot rolled steel doors with interior steel frames that require welding. This allows you to build hot rolled steel doors of immense size that are high precision, just like other types of Sing metal.

Especially if you’re considering utilizing hot rolled steel for your large doors, Sing Core can help to mitigate the damages caused by the heavy weight of hot rolled steel doors with interior steel frames that require welding. This allows you to build hot rolled steel doors of immense size that are high precision, just like other types of Sing metal.

The Sing Core material is extremely high precision (within +/- .006 inch) which keeps your hot rolled steel door straight and flat regardless of its size. The advantages of the straighter and truer big metal doors come in handy when you multiply the door’s required integrity by two when dealing with steel double doors. Double steel doors, especially if they are large and oversized, are fraught with additional challenges.

Sing hot rolled steel can be used for upscale industrial steel doors and in commercial metal door replacements for increased performance and high precision which also supply the project with built in insulation and sound deadening qualities.

Our hot roll steel solutions are changing the scope of architectural metal fabrication because the nature of hot rolled steel is predominantly restrictive due to the weight and framing required to support the raw material. Having access to a lightweight, high strength alternative, like Sing Hot Rolled Steel Panels, opens doors to unencumbered creativity.

Sing Core’s hot rolled steel doors are just some of the best doors that are among the many types of doors that have put us on the map as the best door featured in the most high end jobs across the country and the world.

You will find Sing hot rolled steel panels used not only as a standard swing door but also as hot rolled steel flooring, hot rolled steel counter tops, hot rolled steel wall panels and room dividers, hot rolled steel pivot doors and hot rolled steel sliding doors.

Let Sing hot rolled steel set your creativity free. See also: Steel Fabrication

Click here for hot rolled steel prices.

Hot Rolled Steel Large Sliding Doors

- Insulated honeycomb steel door panels

- Patented honeycomb doors

- Large honeycomb steel panels

- Lightweight honeycomb metal panel

Wide Doors for Hinge or Pivot Door Hardware

Exclusive to multimillion dollar spec homes, the standard extra wide exterior doors are pivot doors to accommodate the unique challenges of wide doors.

Exclusive to multimillion dollar spec homes, the standard extra wide exterior doors are pivot doors to accommodate the unique challenges of wide doors.

The Problem

Wide doors will warp, not just top to bottom but side to side which compromises the seal and creates a problem for latching the door. Wide doors are problematic due to warping requiring regular maintenance to adjust the wide door accordingly.

The Solution

The Sing non-warping Professional Pivot Door Panels are the solution because if the door does not warp, you’ve solved the problem with the failure of wide doors altogether, and can be guaranteed to remain non-warp for 50 years. Even $10,000 wide doors cannot be guaranteed not to warp; even for one day.

This wide door could use concealed door hinges as swing door hinges or pivot door hardware for extra wide exterior doors thanks to Sing Core.

Advantages

Using the Sing non-warp door blank as the basis extra wide exterior doors used in multimillion dollar spec homes is not only the only solution, but also imbues your door with the following benefits:

Using the Sing non-warp door blank as the basis extra wide exterior doors used in multimillion dollar spec homes is not only the only solution, but also imbues your door with the following benefits:

- Lightweight: Sing wide door blanks are 17% the weight of other solid wide wooden doors, i.e. 120 lbs. vs. 720 lbs. at 4 ft. wide door.

- High Strength: Sing wide door blanks are stronger than steel pound-for-pound (660 PSI).

- Insulated: Sing wide door blanks are packed with rigid foam insulation rated at R3.5 per inch at no extra charge for heating/cooling control as well as sound dampening.

- Non-warp: Only Sing wide door blanks can be guaranteed not to warp, bend or twist –including full structure integrity – for 50 years.

Affordable Wide Doors

Expensive pivot doors start at about $10,000 and just the hardware (due to the heavy weight of the door) can run into thousands of dollars and requires highly skilled craftsmen to install/maintain.

Sing wide door are a fraction of the weight and price of extra wide exterior doors. Due to being so lightweight, less expensive pivot door hardware can be used. In fact because Sing wide doors are so light in weight, you can even use standard hinge door hardware. This is why Sing wide door blanks are the premium choice of high end carriage door manufacturers.

Sing wide door are a fraction of the weight and price of extra wide exterior doors. Due to being so lightweight, less expensive pivot door hardware can be used. In fact because Sing wide doors are so light in weight, you can even use standard hinge door hardware. This is why Sing wide door blanks are the premium choice of high end carriage door manufacturers.

Now, wide doors need not be relegated only to million dollar homes, because making them more affordable puts them within the reach of discriminating home owners who would like to increase the impact of their entrance door by switching to an extra wide front door.

Retro-fit Wide Doors

Say, “goodbye,” to sidelites. Sing wide doors can easily be retro-fitted to replace a standard existing exterior front door and sidelites with a single Sing extra wide front door using your choice of side hinges or pivot door hardware.

Sing Wide Doors Always Latch

Sing Wide Doors Always Latch

The difference between sing wide doors and any other extra wide door is that you can always count on one thing: Sing wide doors will always secure and latch every time because they will not warp nearly eliminating wide door maintenance. This high precision can be guaranteed non-warp for 50 years.

Hinge Any Way You Want

Thanks to the light weight of Sing Door blanks, you can choose whether your extra wide exterior doors use side hinges (we suggest considering the use of concealed SOSS hinges) or lightweight pivot door hardware for easy hardware installation.

- Concealed hardware

Professional Pivot Door Panels

Pivot Doors are becoming the most desirable entry door, enhancing the value of high end homes.

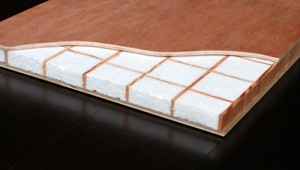

The most cost-effective way to make a pivot door is with patented Sing panels. They are fully insulated with urethane, patented Sing core grid makes it stronger than steel pound for pound, and come with a fifty year non-warp warranty with our professional Sing panels. They are also very lightweight, which can save you hundreds in hardware costs alone, as well as save you on shipping costs, labor, and making installation safer. See also: Wide Doors for Hinge or Pivot Door Hardware

These are the best true-flat, high precision pivot doors available.

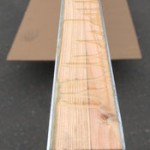

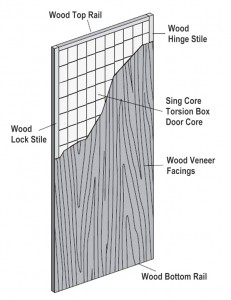

These pivot door panels come standard with frame of 1.5″ wood stiles and 3″ rails, also included 4″ x 12″ wood lock blocks 30” on-center (OC) from bottom.

Standard surface = Luan plywood, upgrade to marine plywood add $100.

You can then lay up whatever skin material you wish: wood stave, steel, stainless steel, FRP or HPL on the surface of Sing pivot door panel or even cut a light opening to satisfy the design of your clients.

The professional Sing pivot door standard panel measures 4 ft x 8 ft x 2.5″ and is untrimmed.

Retail price of pivot doors made with Sing Core pivot door panels often range from $5,000.00 to $10,0000.

Custom oversize pivot doors featuring Sing Core door panels can oftentimes reach $30,000, depending on the skin and finish.

See some of the pivot doors made of patented Sing panel: Pivot Door Gallery

No-fail Pivot Doors

The nature of pivot doors – especially oversized large pivot doors – leads to increased maintenance costs due to warping. When you think of pivot doors warping, you first thought is to think that the door warps along the longest length from top to bottom; it is even more common side to side. Any warp will not only compromise the seal of the door but it will also prevent the door from securing and latching properly. Only Sing pivot doors can be guaranteed not to fail.

Advantages of Professional Sing Pivot Door Panels

ProfessionalSing pivot door panels are the only Eco-friendly lightweight, high strength pivot door blanks that can be guaranteed not to warp or structurally fail for 50 years.

- Lightweight Modern Door

Eco-friendly

Made in the USA professional Sing pivot door panels are manufactured using less natural resources (natural wood), recycled rigid foam and formaldehyde-free adhesives. The manufacturing process uses less energy to produce that creates little or no waste.

Lightweight Hardware

The lightweight nature of a professional Sing pivot door blank means saving thousands of dollars in labor, transportation and installation as well as the heavy duty hardware that would be necessary for a heavier door. For instance, a standard 8 ft. door would weigh-in at 720 lbs. compared to lightweight Sing Core’s 120 lbs. reducing the cost of the hardware significantly. In fact, Sing pivot doors are so light, you could use standard hinges, if you wanted to, without fail.

720 lbs

|

120 lbs

|

High Strength and Non-warp

No other Eco-friendly lightweight pivot door core is so strong nor can compare to Sing Core’s structure strength of 660 PSI. The unique attributes of Sing professional pivot door panels is that they are specially designed with patent pending technology allowing them to be non-warping and structurally guaranteed for 50 years.

Sing Core Patented Torsion Box Panels

We do not sell finished pivot doors, we only supply the Sing pivot door panel for door manufacturers to build the best pivot door.

For overseas transactions there are administrative fees and minimum order restrictions.

How to Fix a Warped Door

Many people struggle with how to fix a warped door. Nothing is more frustrating than spending your hard-earned money on a nice door, only to have it warp, bend, twist or cup not long after installation.

This problem is magnified exponentially especially if the door is a large oversized door. Some of these high-end large doors can cost tens of thousands of dollars only to discover failure due to warp when the season changes. This can mean job security for door repair services, millworks and contractors serving the account, but can lead to dissatisfaction and frustration for the client.

Dealing with how to fix warped wood doors is considered standard maintenance for high-end applications; that was until the invention of patented Sing Core. Only large oversized wood doors made of Sing Core can be guaranteed true flat – and to stay flat – for 50 years. See: No More warped Doors.

Sing Core solves the issues with warping and eliminates the mystery of the warping door. By integrating Sing Core into your door’s composition you can have an elegant, maintenance-free long-lasting door that will not warp, bend, twist or fail regardless of size or application.

Free Door Consultation

The most prestigious clientele around the world seek out expensive door professionals (Certified Door Consultants) to help design doors that meet or exceed the performance standards. We provide free large door consultation to trade professionals to assure that the door that your client receives delivers the high precision performance that they expect.

Click here to see how patented Sing Core door planks/panels/blanks are made providing the only 50 year non-warping guarantee.

Click here to see how patented Sing Core door planks/panels/blanks are made providing the only 50 year non-warping guarantee.

Demystifying Door Warping

There is no longer any need to be frightened of doors warping, due to our extensive experience in providing doors (even huge, enormous doors) that are guaranteed not to warp for 50 years to the most proficient building designers, contractors, mill works and high end door manufacturers.

The biggest problem for doors is warping (especially in large doors) used n high-end home building projects and commercial projects when building sliding doors, pivot doors and big interior doors.

Most door manufacturers and millworks avoid building doors over 8 feet tall or offer a very limited one year warranty with many exclusions/restrictions to prevent exposure to damages due to warping. Click here to see

When you buy your door, and even following installation, it may or may not be flat. Most doors begin to shift and move following manufacture. By the time your door arrives at the job site, it may already be warped or beginning to experience separation between the exterior surfaces and the core material.

Certainly after years of regular use (paper core, foam core) will warp and/or delaminate.

No matter what kind of standard core a door is made from, whether paper core, foam core, SLC (Stave lumber core), particleboard, SCLS (Structure composite lumber), LVL (Laminated veneer), mineral core, MDF, cardboard, etc… warping is inevitable. Even a solid wood door will warp. A sliding or pivot door will have unbearable warp at only ¼ inch due to the reference next to a straight wall or door jam. This warping is even worse in a door over 8 feet because of the strength of the movement. So far, the best solutions have been to only make 7-foot high doors, or to make excuses (i.e., no or very limited warrantees) for doors over 8 feet, or to use gaskets to hide the minor warping, but these are temporary solutions that require costly maintenance and replacement and tarnish the reputations of the building trade professionals involved in the projects. As such, most doors usually do not have warranty protection against the inevitable warping. Even with SCLC (Structure composite lumber core) and LVL (Laminated veneer), commonly used in high end large door will not remain true flat due to the wood fiber constantly moving.

No matter what kind of standard core a door is made from, whether paper core, foam core, SLC (Stave lumber core), particleboard, SCLS (Structure composite lumber), LVL (Laminated veneer), mineral core, MDF, cardboard, etc… warping is inevitable. Even a solid wood door will warp. A sliding or pivot door will have unbearable warp at only ¼ inch due to the reference next to a straight wall or door jam. This warping is even worse in a door over 8 feet because of the strength of the movement. So far, the best solutions have been to only make 7-foot high doors, or to make excuses (i.e., no or very limited warrantees) for doors over 8 feet, or to use gaskets to hide the minor warping, but these are temporary solutions that require costly maintenance and replacement and tarnish the reputations of the building trade professionals involved in the projects. As such, most doors usually do not have warranty protection against the inevitable warping. Even with SCLC (Structure composite lumber core) and LVL (Laminated veneer), commonly used in high end large door will not remain true flat due to the wood fiber constantly moving.

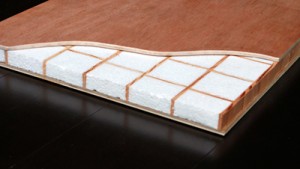

Finally, Sing Core provides a guaranteed solution to the challenges of warped doors and it is the only affordable lightweight high strength solution that can provide 50 years of high performance, remaining straight and true without fail. Plus, Sing Core offers insulation qualities that cannot be found in other strong (heavy) building materials. Only this unique patented torsion box/rigid foam composite can offer the superior strength – bridging long spans, or towering heights – while insulating and providing sound deadening benefits.

Sing Core helps door manufacturers and mill workers build doors which satisfy even the most challenging high-end door market. (Click here to see our client list.) Doors made with our patented Sing core panels are true flat and may be guaranteed to stay true flat for 50 years. In addition, our patented Sing Panels (door blanks) are:

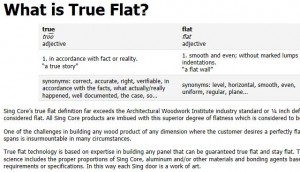

1. Dimensionally stable with a high precision tolerance of +/- .006 inch. This is laser precision which produces the smoothest and most true-flat panels.

2. Fully insulated for temperature control and sound-deadening qualities and which are 3 to 5 times more insulated than solid wood-based door cores.

3. Lightweight so that even a 4 inch thick door will weigh only 2 to 3 pounds per square foot. An average wood-core weighs 8 to 10 times more than our patented Sing core.

4. High strength which has been verified by the University of Washington at above 660 PSI, making our Sing panels pound-for-pound stronger than steel. (You could drive a 12,000-pound forklift over them without crushing them!)

5. Water-resistance/waterproof doors made of patented Sing core panels can be completely exposed to the weather without warping. (Click here to see our exterior door gallery.)

6. Eco-friendly and non-toxic structure glue for bonding skins and Sing core.

- Click the picture to see our hardwood plan gallery!

Aluminum skin only for paint grade or wood stave.

- lightweight high strength large honeycomb door

Add MDF skin or plywood for paint grade and wood grain.

Click here to see how patented Sing core door planks/door panels/door blanks produce true flat stay flat (non-warping) doors in any size, shape or design with a 50-year guarantee. Call us for a free consultation at (360) 495-3577.

- Add molding to create stile and rail door appearance

- Oversize wood grain pivot doorlightweight

- lightweight high strength sing honeycomb door

- sing honeycomb lightweight sandwich wood sliding door honeycomb lightweight sandwich wood

- exterior lightweight honeycomb door

- lightweight high strength sing honeycomb sandwich

- True Raised Panel Doors

High Precision Doors

Sing High Precision Doors are a marked improvement in door development, design and implementation thanks to a newly invented Eco-friendly core material that is lightweight, insulated and stronger than steel pound for pound.

Sing High Precision Doors are a marked improvement in door development, design and implementation thanks to a newly invented Eco-friendly core material that is lightweight, insulated and stronger than steel pound for pound.

This new technology is revolutionizing the door industry especially in regards to large oversize doors. Architects, designers, mill works and door manufacturers all experience problems with doors that are larger than normal size.

Large doors present a variety of challenges in areas, like:

- choice of available materials

- lightweight doors are weak and tend to fail

heavy doors strain hardware and structure

heavy doors strain hardware and structure- increased regular maintenance

- failure due to warping

Sing High Precision Doors solve all these issues with an Eco-friendly insulated solution.

How high precision are Sing High Precision Doors?

Sing High Precision doors are created with so much accuracy that the original door slabs are perfectly flat within .0006 inch accuracy.

After applying your desired composite materials and/or skin, your high precision door can be laser CNC machined for a perfectly flat surface, limited only by the accuracy of your CNC machine shop capabilities.

The Large Challenge

Certainly, you could use laser CNC cutting and engraving to machine nearly any door made of almost any commonly used door material for a flat result. The challenge comes from standing the door upright and expecting a degree of effective usefulness over time.

The effects of gravity, varying degrees of moisture and/or atmospheric change, and the natural limitations of the characteristics of the building materials that comprise the door all contribute to its failure. This causes dissatisfaction for the end user, who has invested a great deal of expense in the design, manufacture and installation of this specialty large door.

Door warping is the number one problem for oversized doors that are otherwise enjoyed by the most discriminating end users.

The Disappointment

No one wants to spend that kind of money on a door that is going to warp, bend, twist, delaminate or compromise the structure or hardware with normal recommended use.

Now, here’s the exciting part…

Sing High Precision Doors can be guaranteed not to warp, bend twist or otherwise fail for 50 years!

Imagine having a large door that can be installed that will not pave the way for repeated service calls over the life of the door.

Imagine having a large door that can be installed that will not pave the way for repeated service calls over the life of the door.

Take a look at some of our clients who trust us with those difficult door challenges because they are the most reputable high performers in the industry who only deliver the highest marks in terms of customer satisfaction, especially now that they can deliver a fail-free large door that will not cause frustration for their client’s or their service departments. See clients List.

Highest Precision in Doors

No other building material can be guaranteed to maintain a true flat surface and milled with laser precision for long-term maintenance-free performance for 50 years. This is why you can find the growing demand for the Sing solution from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

No other building material can be guaranteed to maintain a true flat surface and milled with laser precision for long-term maintenance-free performance for 50 years. This is why you can find the growing demand for the Sing solution from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

The high precision Sing solution is not just for doors; turned flat these very same Sing Panels can become floors, tables, counter tops, ceilings and roofs. Turned on their sides, these patented panels become walls, moveable partitions or virtually any other type of application.

Solid Wood Stave Door Blanks

Applications -> Building Components -> Doors -> Solid Wood Blank Doors

Our panels make doors!

Patented Sing Core solid wood stave door blanks feature the newest technology in the door industry for composite doors yielding the only eco-friendly, lightweight, fully insulated, high-strength doors with wood blanks of any size (up to 40 ft.) that can be guaranteed true flat and to stay flat for 50 years.

Large door versus regular-size door challenge (i.e., over 4 feet wide and over 8 feet in length):

Large doors are heavy, dimensionally unstable, require more strength due to the heavy weight, and are a challenge to manufacture, ship and install. High-end jobs require precision and true flatness to please the customer. A homeowner’s architect, general contractor and mill worker must solve the problem of warping doors. The solution to the challenge is to use patented professional true flat Sing panels to make your doors.

Sing Core wood stave door planks are the only solid wood doors that will not warp, bend, twist or cup following installation. This means no more continuous service calls for maintenance of big doors that cannot possibly stay straight due to the limitations of solid wood – or any other door core – that is subject to failure. Sing panels have a patented honeycomb/torsion box interior which gives lightweight yet unsurpassed strength (pound-per-pound stronger than steel) and stability to any door, and allows Sing Core to provide a 50-year guarantee

Sing panels make amazing designer doors in any style. With Sing panels, fragile doors such as French doors are made lightweight yet strong, not warping or breaking hinges, which will last for many decades.

Sing panels make sturdy exterior doors in any style. With Sing panels, exterior doors are lightweight and strong, even when oversized. Our professional doors are guaranteed to stay true flat and not warp or twist for 50 years

The problem is that all door core materials are either not high precision, too heavy or will move when exposed to moisture, humidity or change in temperature resulting in door failure.

Heavy solid metal or steel will not warp, bend or twist, but is not high precision due to welding (sing core tolerance is + or – .006 inch!) and is often impractical due to the overweight issues causing excess strain on both the hardware and structure, causing continued maintenance issues. The solution is our patented lightweight yet strong Sing core technology.

Finishing a door blank:

There are two types of finish for door blanks: paint grade and wood grain. Paint grade includes such finishes as metal, Masonite, marine plywood, etc. Wood grain finish includes such finish as solid wood stave and thin veneer.

Why Use Solid Wood Instead of Veneer?

Never settle for substandard veneer doors again. Door engineers prefer to use inexpensive veneer as opposed to real solid wood facings because veneer is thought to be less likely to warp, bend or twist. But thanks to the super-strength of patented Sing Core technology, you can use solid wood stave and wood blanks with confidence knowing that your door can be guaranteed true flat and will stay flat.

How can a solid wood-faced door stay true flat? As every woodworker knows, when using a solid wood surface, the grain will move according to moisture or temperature change causing the door to fail. When using our patented Sing Core as a substrate you can safely use solid wood because the solid torsion box/honeycomb patented material is continually keeping the wood grain straight and true. Whereas wood stave has more wood fiber giving it more of a chance to warp than thin veneer due to the unbalance of the both side of the door moisture contents, patented Sing technology solves this problem by combining stiffing skin on both side of our patented Sing core. This Sing panel technology eliminates the troublesome movement of the door blank — warping is no longer a concern when wood stave is combined with patented Sing core.

In addition, solid wood is easy to work with, install (no need to hot press), repair and remodel. That’s why professionals trust Sing Core’s years of expertise in helping to design the only wood stave doors (that look just like solid wood doors) that can stay straight and true for many decades while respectfully honoring the beauty and elegance of solid wood, which far outlasts easily-damaged veneers, yet can be sanded and repaired if necessary.

Celebrate your real wood!

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize doors.

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize doors.

That’s why this technology is found everywhere, from beneath the sea (US Navy) to outer space (NASA) and everywhere in-between.

Sing panels may be finished in almost any wood species, like mahogany, redwood, teak wood, cherry wood, walnut wood, cedar wood, Ipe wood, sapele wood, poplar wood, ebony wood, ash wood, oak or any other hardwood or exotic wood types available.

This same wood blank composite technology is also a common solution for high-end projects like engineered hardwood flooring, shiplap, wood furniture, wood shelves, decking, shed doors or any other application demanding high precision and exemplary performance over time.

How is wood stave/veneer added to Sing panels?

Aloha Non-warping Hawaiian Large Doors

Aloha from Honolulu, Hawaii, where Professional Sing non-warping doors are making an impact.

Hawaiian door manufacturer sought out Sing Core in search of a non-warping exterior door solution for rigorous climate variances especially large oversized sliding doors and pivot doors.

During the free consultation, the manufacturer explains that large doors are known for warping top to bottom, but people don’t talk much about warping side-to-side, which makes it a constant struggle for latching and sealing the door. These are the constant issues that face the makers of large exterior doors.

The specifications for the door included a natural Sapele wood stave exterior which complicates the door project even more because the innate natural wood grain will have a tendency to warp, bend and twist according to changes in temperature and humidity.

The specifications for the door included a natural Sapele wood stave exterior which complicates the door project even more because the innate natural wood grain will have a tendency to warp, bend and twist according to changes in temperature and humidity.

Door manufacturers find it hard to believe that inventor Peter Sing would be willing to, “put his neck out on the line for 50 years.” It is this 50 year non-warp and structure guarantee that intrigues manufacturers of larger doors, especially if the door specs include exposed solid wood.

The undeniable fact is, patented Professional Sing Core is the only way to build a lightweight, high strength non-warp door. And Sing Doors are guaranteed not to warp – top-to-bottom or side-to-side – for 50 years including full structure guaranteed also.

We are the best door substrate for doors, not just in the continental USA, where we are best-known but also in Alaska and Hawaii, when it comes to the most prestigious big doors.

Here’s an example of a 98” x 84” x 3” Professional Sing Door with custom lite cutouts for a modern pivot door presentation and 1/8” Sapele wood stave exterior, weighing in at only 250 lbs.

Pricing for Homeowners

For Homeowners Who Care How Things Are Built

Homeowners who value craftsmanship, longevity, and performance often ask for Sing Core by name. It’s what many architects and fabricators choose when flatness, strength, and long-term stability truly matter.

While Sing Core products are used in residential projects across the country, they are not sold directly to homeowners or through retail channels. Sing Core is a behind-the-scenes material, trusted by professionals and built into some of the most refined doors, walls, and architectural elements in high-end homes.

If you’re planning a project and want the best possible foundation, simply tell your team you want

“Sing Core inside.”

What Sing Core Provides

Sing Core manufactures unfinished, high-performance structural panels that serve as the foundation for premium architectural work.

We focus on what we do best

• Flatness that stays flat

• Strength without unnecessary weight

• Stability that resists warping over time

Our professional partners take it from there, designing, fabricating, finishing, and installing beautiful finished products using Sing Core at the core.

What Sing Core Does Not Provide

To ensure the highest quality outcomes, Sing Core does not sell finished products to retail customers and does not provide

• Finished doors

• Hardware or hardware preparation

• Finishing or installation services

These steps are handled by skilled architects, millwork shops, and door manufacturers who specialize in turning high-performance materials into refined finished pieces.

How to Use Sing Core in Your Home

Step 1: Define your intent

Have a general sense of

• What you want to build

• Approximate sizes and quantities

• The look or exterior material you’re after

Step 2: Choose the right professional

Work with an architect, designer, contractor, door company, or millwork shop experienced in high-end residential work.

Step 3: Ask for Sing Core

Your professional will coordinate directly with Sing Core to specify the correct panel construction for your project.

Why Professionals (and Their Clients) Choose Sing Core

Sing Core is selected for projects that demand more than standard construction can deliver

• Lightweight yet exceptionally strong

• Insulated and energy-efficient

• Dimensionally stable

• Environmentally responsible

• Proven in demanding architectural applications

From large doors to architectural panels and custom furniture, Sing Core is built for performance that lasts, quietly doing its job for decades.

A Note on Support

Sing Core works exclusively with trade professionals. Your architect or fabricator is your guide through design, fabrication, finishing, and installation decisions. This ensures your project is executed by experts who understand both the material and the final application.

For homeowners, the path is simple

Choose your team

Ask for Sing Core inside

Enjoy a result that performs as beautifully as it looks