The Most Beautiful Tiny House in the World

The Most Beautiful Tiny House in the World

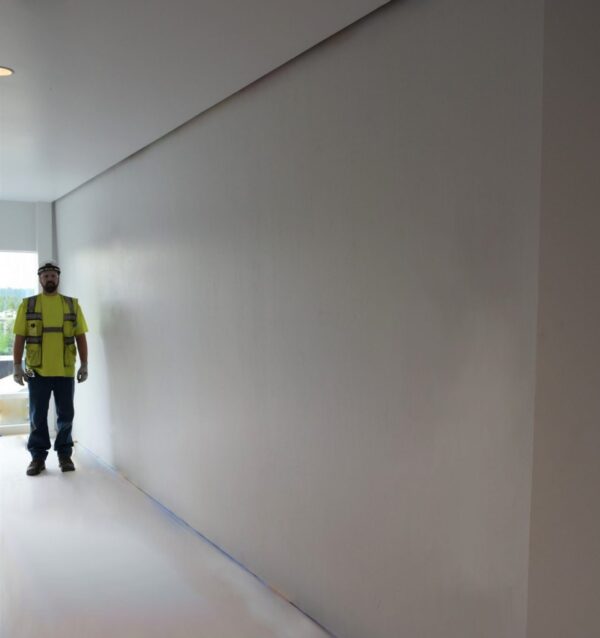

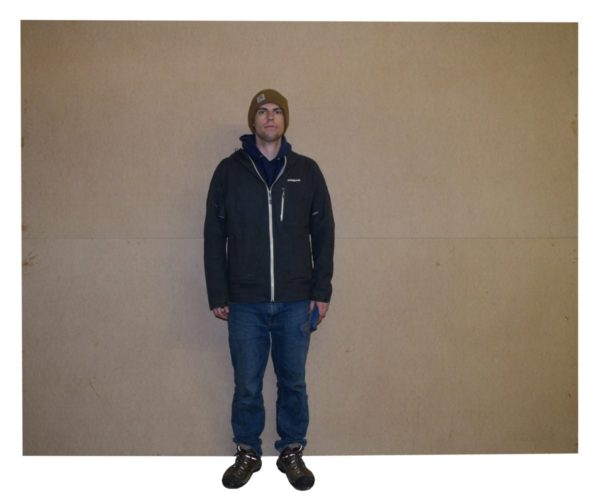

When an artist and craftsman comes to you and asks “what materials would be best to use in the making of the most impressive hand-tooled woodworking tiny house project?” The answer could very well be “Sing Core.” The inventor of Sing Core, Peter Sing, asked the creator of this beautifully executed project that could easily […]

How to Build a Tiny House Photos

How to Build a Tiny House Photos

There are many ways to build a Sing Tiny House. Here’s an step-by-step example of a highly energy efficient tiny house with R-27 walls being built from scratch. How to Build a Tiny House Photos Fill out my online form. Tiny House News See Also: Free Tiny House eBook Tiny House How to Build […]

Tiny House Reinforced Structural Insulated Panels Home Improvement

Tiny House Reinforced Structural Insulated Panels Home Improvement

Sing Core is proud to announce that their Sing Sandwich panels are now conveniently available at your local Lowe’s Home Improvement Warehouse. Why Build a Tiny House with Sing? There are so many reasons but the most popular ones are: Fastest and easiest tiny house building Why spend weeks building your tiny house, when you […]

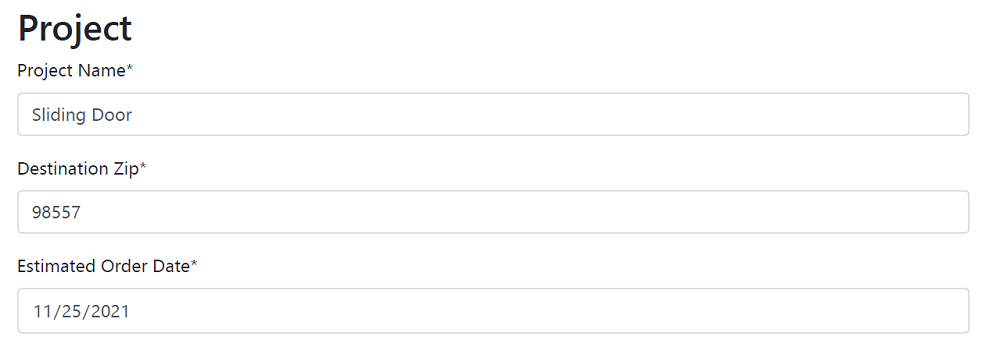

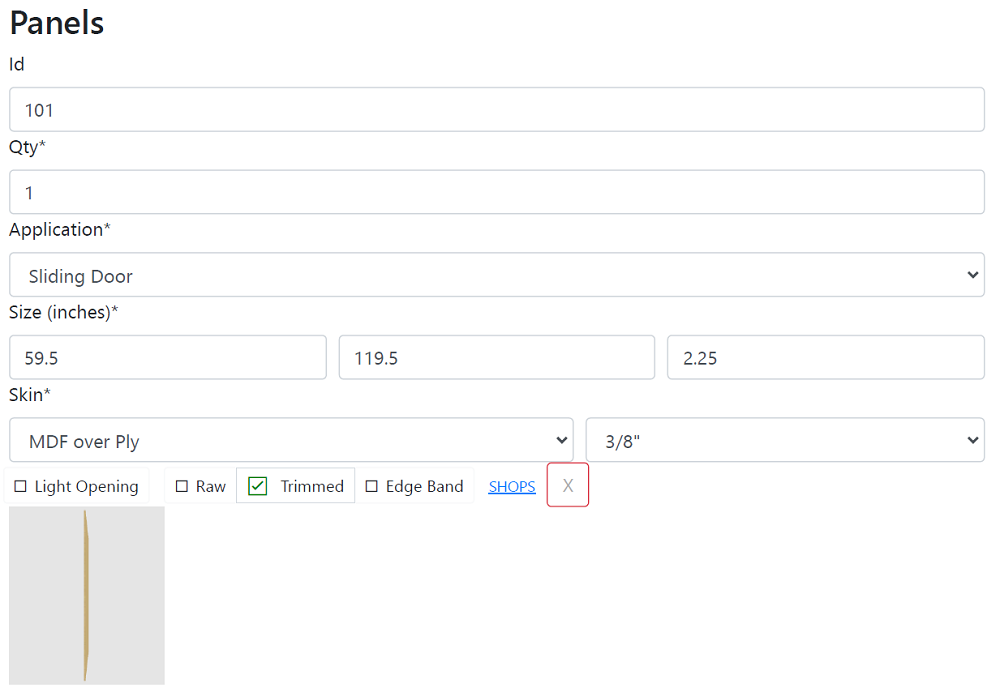

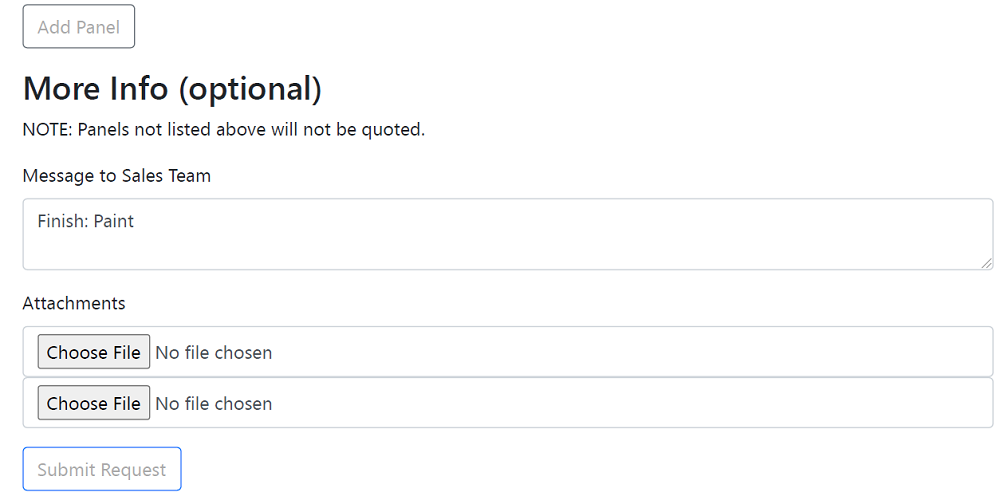

How to Design, Order and Build your Tiny House

How to Design, Order and Build your Tiny House

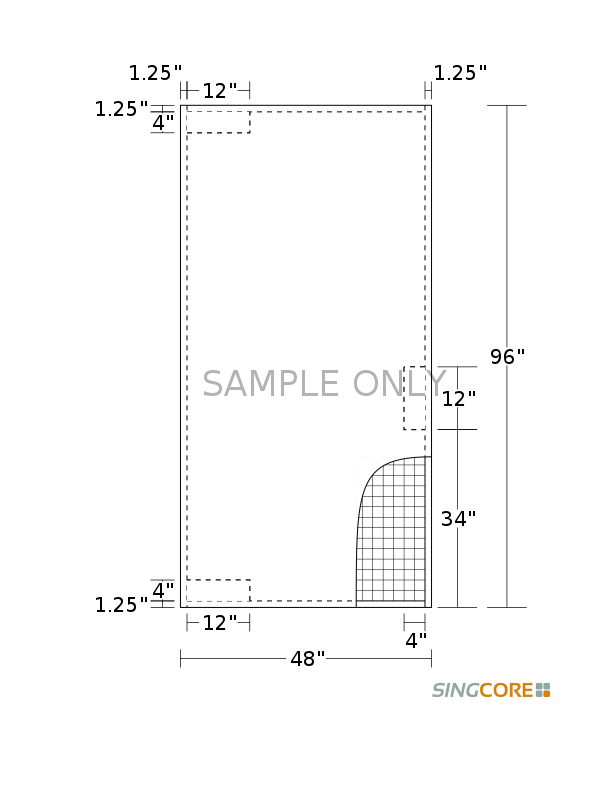

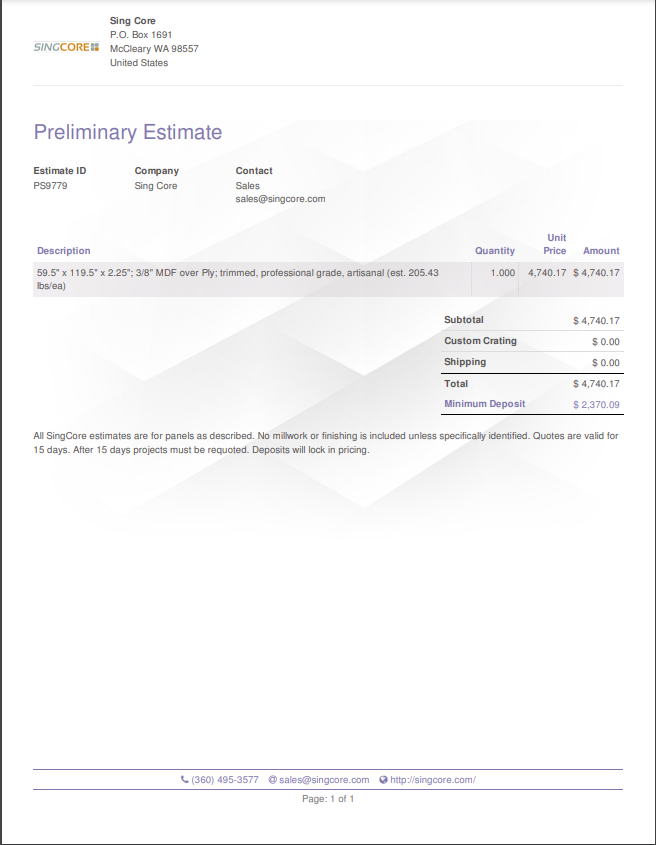

Patented Sing Core has endless applications. Because some of the finest, high-end tiny houses are built using Sing technology, we get a lot of calls about using Sing Panels in tiny house designs with varying degrees of preparation. We work with architects and designers who have the concept completed, and they order the number panels […]

Shop Tiny House

Shop Tiny House

Breaking News Sing Core took the Seattle Home Show by storm in 2019 by introducing a new concept in Tiny House building and design. This year Sing Core rolled out a two-and-a-half story tiny house that would be too tall to transfer via public highways. That is, unless the top folded down upon itself so […]

Upscale High-end Tiny House

Upscale High-end Tiny House

Many people, who stick their toe in the water of the Tiny House movement, are lulled by the inexpensive option(s) associated with living affordably in a structure that is a fraction of the square footage of a larger home. To some this makes perfect sense and is an Eco-friendly approach to living more simply for […]

Tiny House Mobile Small Home on Wheels

Tiny House Mobile Small Home on Wheels

Patented Sing Panels have been used in many industries such as home building, boat building even in the aircraft industry. Making its way to the forefront recently are advancements being recognized by the tiny house community. These tiny house designs are springing up all over the United States (and the world) in the smallest footprints […]

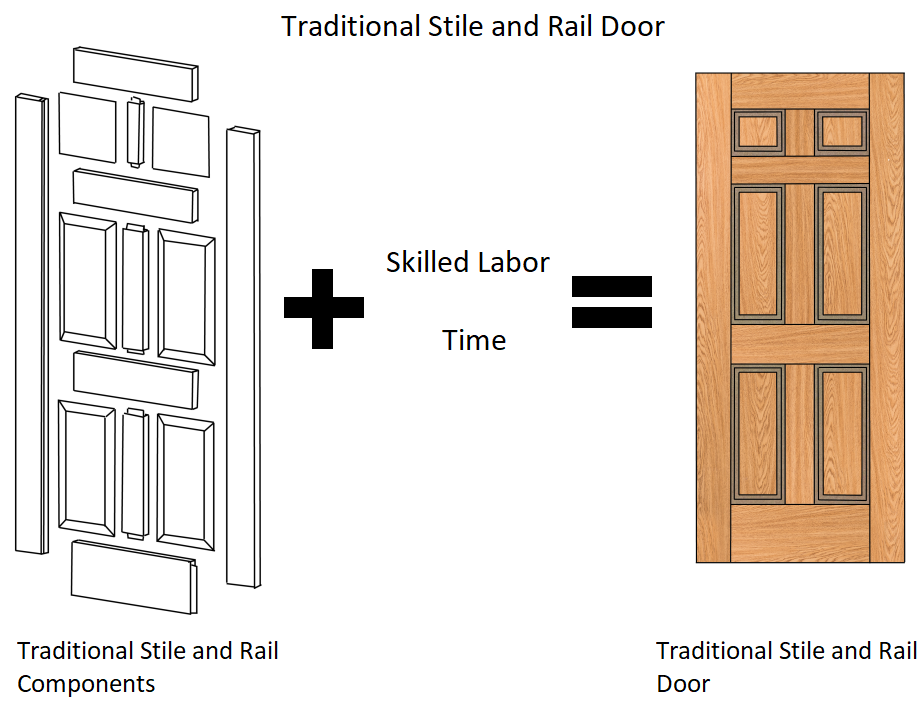

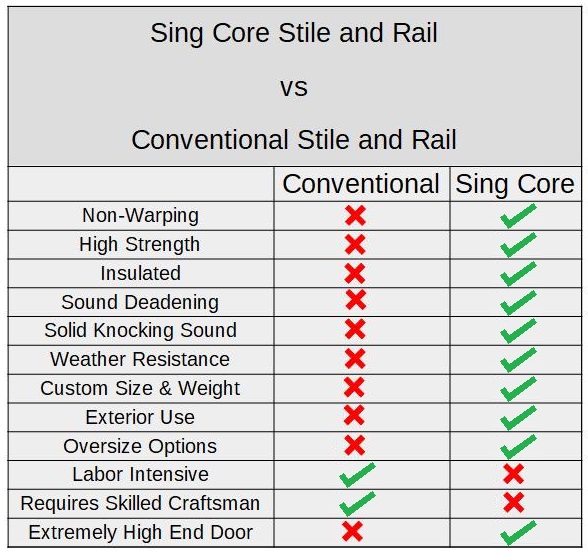

Tiny House How to Build

Tiny House How to Build

Sing Tiny House: How to build a Tiny House completely with Insulated Sing Honeycomb Panels Step Step 1 Lie Sing Honeycomb panels on top of a treated timber foundation frame and fasten with screws. Step 2 Connect floor and wall panels together using glue and screws. Step 3 Remove bits of honeycomb core to implant […]

Tiny House FAQ

Tiny House FAQ

Home -> Products -> Applications -> Tiny House -> Tiny House FAQ Tiny House FAQ 1) How can I get Sing Panels to use in my Tiny House? The demand for Sing Sandwich Panels in tiny house building is huge, be aware that we do not sell to end-users, only wholesale (unless you are purchasing a Sing […]

Folding Modular House Competition

Folding Modular House Competition

Four years ago a company introduced a concept that was recently presented to Sing Core. An excellent idea that did not work out well due to not having access to the adequate building materials. This aluminum shelter was a great idea and design, being unfolded and assembled quickly is a magnificent concept for a temporary […]

Smallest House in the World

Smallest House in the World

The Smallest House in the World can have all the conveniences of home in such a small space: Assembles quickly (easily in 10 minutes) Small quality living space Insulated floor and walls Easy to heat Very strong (can survive hurricane or earthquake) Plenty of headroom for Standing Exercising Pacing Plenty of room area to stretch […]