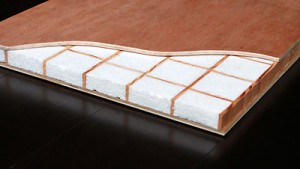

- Lightweight strong painted door

- Insulated non warping garage door

Guaranteed: Less labor, less material cost to build the best lightweight, high-strength (any type of) door using patented Sing Core technology and you can be licensed to manufacture it yourself.

Guaranteed: Less labor, less material cost to build the best lightweight, high-strength (any type of) door using patented Sing Core technology and you can be licensed to manufacture it yourself.

Inventor Peter Sing would like to talk to your owner/CEO about partnering with your door company to manufacture his patented door core at your facility.

You’ve probably heard about Sing door core’s ability to create super-large doors that are lightweight, high-strength (stronger than steel), true flat and guaranteed to stay flat for 50 years. This is why the most high-end millworks and corporations, like NASA, Boeing and the United States Military branches depend on us out for their large insulated door applications.

We are looking for a door company, like yours, to manufacture the patented door core. This would allow you to manufacture doors using this advanced technology with very little expense. We will teach you everything you need to know and Mr. Sing will guide you through the whole process and help set-up your factory.

If you’re interested, Contact Us

360-495-3577

Sing Post & Beam Gantry |

Post & Beam Trade Show |

Post & Beam Structure |

We are so thrilled to see that sustainably conscious Tiny House designers and builders are embracing patented Sing technology to build the most sophisticated tiny houses in the world.

We are so thrilled to see that sustainably conscious Tiny House designers and builders are embracing patented Sing technology to build the most sophisticated tiny houses in the world.

The advantages of building a Tiny House using Sing Reinforced Structural Insulated Panels are well known. No other system offers Eco-friendly frameless technology that is lightweight, stronger than steel pound for pound and pre-insulated.

We love the Tiny House movement and fully support the idea of living small for a better world. In our effort to further support the proliferation of tiny houses equipped with all the benefits of Sing technology, we are offering 50% off our Tiny House Kits as well as any additional Sing Panels that you may need to make your dream come true and complete your tiny house project.

High-end upscale tiny homes

When choosing panels for tiny homes, Sing panels are the highest in quality and durability. Click here to learn more.

We are huge fans of tiny houses but do not have the staff or time available to do R&D in terms of Tiny House design because we are so busy serving our other clients. See: How to Design and Build your Tiny House. To better serve you, we are issuing a challenge to the greater tiny house community:

Not only will we help to subsidize build your Tiny House using Sing technology, but we want to encourage you to build the best Tiny House and share your story with us.

The tiny house builders and owners who submit their completed Tiny Houses built with Sing technology will be featured on our Web Site (and others) and fans and visitors will help to comment and vote on your Sing Tiny House project.

Winners will receive a

If your Tiny House project is chosen amongst the winners, you will be rewarded with a free Tiny House Kit to build another tiny house, the same size as your tiny house entry.

Use the free tiny house in any way you choose, use it as a shop or guest room, sell it, give it away, donate it to the homeless shelter, whatever is your heart’s desire.

Don’t forget, you could also get a Free Tiny House by helping us to spread the word by joining our Sing Tiny House Referral Program to earn your Sing Tiny House Kits..