It is not uncommon for potential Sing products users to get overwhelmed by the ever expanding wide variety of products and applications of Sing Core. There are hundreds of Sing products available covering dozens of industries, but the pricing method is just as simple as buying lumber or solid metal.

It is not uncommon for potential Sing products users to get overwhelmed by the ever expanding wide variety of products and applications of Sing Core. There are hundreds of Sing products available covering dozens of industries, but the pricing method is just as simple as buying lumber or solid metal.

We understand that it is easy to get confused… but as vast as our offerings are, our ordering and pricing process is very simple and easy.

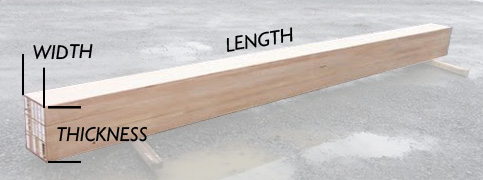

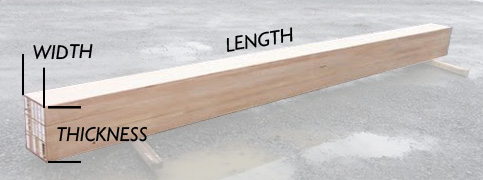

Basically, everything we make is a panel, post or beam. Every order can be broken down into 3 measurements: the length, width and thickness. Then the only piece that you have, after that, is what surface you want on your end product; we call that the “skin.” It really is that easy: we have reduced everything down to a unique, standard ordering process.

PRICE = LENGTH + WIDTH + THICKNESS + SKIN

|

Ordering is as just as easy as any lumber or solid metal, except instead of specifying the wood species, you tell us the final “skin” of the surface material. Check out our pricing section to see how easy it is.

Simple Process

Sing Core has made the process simple enough to get this material into the hands of the people who would like to enjoy long-lasting maintenance-free enjoyment of their projects or products while making the world a better place by using his Eco-friendly lightweight high-strength building material.

Skin Options

Basically, patented Sing Core can host any flat surface material. To date, these are the most popular:

Any Wood Species

Sing Wood

Non-warping Sing Wood Planks are growing in popularity among the architectural community used for door, floors, ceilings, siding and scaffolding.

2-5-1-1. Aluminum

One of our most popular Sing Core surface material is aluminum due to its unique properties, especially when maintaining true flatness over a long spans.

One of our most popular Sing Core surface material is aluminum due to its unique properties, especially when maintaining true flatness over a long spans.

Standard aluminum facing material sizes are:

For more information on Sing aluminum materials see Sing Aluminum

2-5-1. Metal

Expanding on the widespread potentials of Sing Core, metal is used in order to imbue it with essential attributes for specific design integration, solving the problems of lightweight without compromising strength (as Sing Core bonded with metal is actual stronger than solid metal).

Expanding on the widespread potentials of Sing Core, metal is used in order to imbue it with essential attributes for specific design integration, solving the problems of lightweight without compromising strength (as Sing Core bonded with metal is actual stronger than solid metal).

Standard metal panels are lighter and stronger than steel and available in the following metals:

- Aluminum

- Tin

- Colled-rolled steel

- Galvonized steel

- Hot rolled steel

- Stainless steel

- Stainless diamondplate

That is just a sample of the many varieties of metal that can be used to house Sing Core. We can use nearly any metal material to accommodate your needs while resulting in a superior end product.

For More information of Sing Metal, see Metal Index

2-5-3. FRP Fiberglass

Fiberglass, FRP and plastic skins are popular exterior surfaces for Sing Core. A variety of options exist, for more information, see Fiberglass Index

2-5-4. HPL High Pressure Laminate

High Pressure Laminate (HPL) is resistant to abrasion, high temperatures, shock, flame and can be used in both interior and exterior applications.

Available in standard thicknesses: .020, .040

2-5-5. Cement Board

Cement board is a versatile Sing Core exterior due to its unique properties of water resistance, will not mold, mildew or physically break down in the continued presence of moisture or leaks.

Available in standard thickness: 1/8”, 1/4″

Other surface materials include:

– MDF

– Hardboard

Decorative Surfaces

– Thermally Fused Laminate (TFL)

– Decorative Paper/Foils

– 3D Laminates

– Continuously Pressed Laminate (CPL)

– Engineered/Value Added Veneers

– Decorative Metals

– Polypropylene Film

– Polyester

– Solid Surface

… And nearly any other building material known to man…

Sing Core technology is manifested in so many ways we’ve tried to narrow down the basics to make the possibilities easy to comprehend.

Sing Core technology is manifested in so many ways we’ve tried to narrow down the basics to make the possibilities easy to comprehend.

What are Sing Composites?

Sing Composites are the combining of different abundant raw materials for the greater good. Sing Composites are:

- Stronger

- Lightweight

- Eco-friendly

While reducing:

- Waste

- Energy

- Production costs

- Labor costs

- Shipping costs

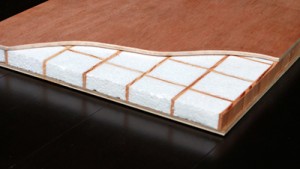

To understand Sing Core technology, you must understand that in all Sing Core products the Sing Core is the actual core of the product that produces the vast number of characteristics that make up the Sing Core line.

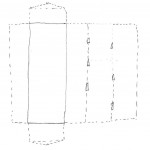

Sing Core with two exterior skins is a Sing Sandwich Panel, adding solid edges makes a Sing Panel. Basically, all the products listed below are Sing Panels, separated into shape, size and dimensional categories and primarily feature wood exteriors, but could be available in nearly any exterior material. We do all this, and make it affordable to have the greatest impact on the world.

All Sing Core products share the same exceptional characteristics.

Best Seller, the most versatile: 2×12

There are three basic formats for demonstrating the attributes of the Sing Core material, they are:

1. Sing Plywood

Sing Plywood enables you to use a lightweight, strong, wooden torsion-box panel empowering you to create anything from basic furniture, large sliding doors or to create affordable housing with unparalleled longevity.

Sing Plywood enables you to use a lightweight, strong, wooden torsion-box panel empowering you to create anything from basic furniture, large sliding doors or to create affordable housing with unparalleled longevity.

- available in large almost seamless oversized panels

- as large as 12 ft wide x 48 ft in length

- as thin as 1/2 inch

- Can be as much as 6 inches thick

Oversize Sing Plywood will have the tightest seam that will not shift due to patented technology, making it guaranteed to maintain structural integrity and seal, unlike solid wood.

With an appearance identical to traditional plywood, the physical characteristics are nothing short of shocking in comparison, as Patented Sing Plywood

2. Sing Planks

Sing Core Wood Planks are elongated and rectangular solid wood on six sides, a lightweight super-strong eco-friendly alternative to solid wood material used in carpentry and the construction of ships, houses, bridges and other structures.

Sing Core Wood Planks are elongated and rectangular solid wood on six sides, a lightweight super-strong eco-friendly alternative to solid wood material used in carpentry and the construction of ships, houses, bridges and other structures.

In stock standard sizes of Sing Planks:

Sing wood planks are available in any width from eight to twelve inches, any thickness from 1/8 inch to six inches and any length up to 50 feet long.

A variety of options are available for your Sing Wood Planks

3. Sing Post and Beam

Sing Posts and Beams are more dimensionally stable and structurally sound than any other building material; maintaining unparalleled strength over long spans, while remaining lightweight. Sing Posts and beams are super strong and resistant to rot, weather and temperature variations, warp and twist.

Sing Posts and Beams are more dimensionally stable and structurally sound than any other building material; maintaining unparalleled strength over long spans, while remaining lightweight. Sing Posts and beams are super strong and resistant to rot, weather and temperature variations, warp and twist.

In stock standard sizes of Sing Posts and Beams:

- 4×4

- 4 x 6

- 5 x 8

- 6 x 8

- 8 x 8

- 8 x 10

- 8 x 12

Sing Posts and Beams are available in any width from four to twelve inches, any thickness from 4 inches to forty-eight inches and any length up to 50 feet long.

Sing Laminate Beams replace oversize traditional laminate beams sporting superior strength and lightweight, while retaining all the natural wood beauty. For more information, see Sing Post and Beam

Sing Core Menu

| SKIN |

Thickness |

PANEL |

PLANK |

POST & BEAM |

CUSTOM |

| Plywood |

1/8″ – 1 1/8″ |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Wood Stave |

1/8″ |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Wood Plank |

1/4″ – 2″ |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Aluminum |

.020 – .090 |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Metal |

varies |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Fiberglass |

varies |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| HPL |

.020 – .040 |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

| Cement Bd |

1/8 – 1/4 |

4 x 8 – 4 x 16 |

2″ x 6″ – 2″ x 24″ |

4″ x 4″ – 12″ x 12″ |

Almost any size… |

The surface material that is featured on Sing Core material greatly enhances the characteristics of the end product and endows it with unique properties for a variety of products and applications. Examples include:

Plywood / Wood Veneer

When Sing Core is sandwiched between two exterior skins of plywood, the result is a building material that is unmatched in the world of standard building materials due to the increased strength and lightweight properties of the end product, as well as resistance to warp and twist.

When Sing Core is sandwiched between two exterior skins of plywood, the result is a building material that is unmatched in the world of standard building materials due to the increased strength and lightweight properties of the end product, as well as resistance to warp and twist.

Standard plywood exterior surfaces are available in

You may specify the individual characteristics of the plywood used to your specifications. For more information, see: Sing Plywood

Wood Stave

Woodstaves (a narrow length of wood “stave” with a slightly beveled edge) can be utilized to form the exterior of Sing Core. These can be used to replace other types of solid wood building materials.

Woodstaves (a narrow length of wood “stave” with a slightly beveled edge) can be utilized to form the exterior of Sing Core. These can be used to replace other types of solid wood building materials.

Standard wood stave exterior measures:

Other thicknesses of wood stave may be available upon request, in nearly any wood species.

For more information on Sing Core’s wood staves, see Wood Staves

Wood Plank

Sandwiching Sing Core between two wood planks results in an incredibly strong structural-strength building material, that will remain straight and true, lasting the test of time.

Sandwiching Sing Core between two wood planks results in an incredibly strong structural-strength building material, that will remain straight and true, lasting the test of time.

Standard wood plank thicknesses include:

- 1/4″

- 1/2”

- 3/4″

- 1”

- 1 1/2″

- 2”

Other thicknesses are available upon request per your specifications. Fore more information, see Sing Wood Planks

Keep in mind that any Sing product may feature any of the following:

- Aluminium of various grades and finishes

- Metals and Steels including painted, primed, galvanised and stainless grades

- Lead (used especially as a facing for construction/lining panels in radiology areas)

- Rubber and Plastics; a wide range including GRP, PVC, Acrylic, Polycarbonate and ABS

- Lightweight/Insulation Foams; many types including EPS, XPS, PU, PIR, Phenolic, all with differing characteristics and levels of mechanical and compressive strength, insulation and fire resistance.

- Wood based sheets; all types such as plywood, MDF, OSB and particle board

- Decorative HP laminates of all types

- Dry Lining or Plasterboards based on Cement, Gypsum or other compositions with high fire resistant and sound insulation properties.

And product can be customized with any combination of composite materials to meet your requirements or specifications.

Sing Core is the manufacturer of our patented invention and as such we are not qualified to deal with or train end users on the uses for – or handling of – the building material itself.

If you want to use patented Sing products in your upcoming project, there are ways you can make that happen.

1 – If you are a manufacturer, millwork, high-end woodcraftsman and you already have a commercial account with us, then you have access to our materials – including the rare, high-end one-off custom projects that we help to solve every day. If you are a high-end retail establishment, you may be eligible for a commercial account. Please contact us and find out, today.

1 – If you are a manufacturer, millwork, high-end woodcraftsman and you already have a commercial account with us, then you have access to our materials – including the rare, high-end one-off custom projects that we help to solve every day. If you are a high-end retail establishment, you may be eligible for a commercial account. Please contact us and find out, today.

2 – Lumber retailers and sheet product distributors are invited to carry regularly stocked Sing Core products that retail well to local builders, contractors, woodworkers and DIY homeowners.

3 – DIY creative artists are supported by Sing Core indirectly. Though we do not have support available for the end-user, we do provide all the necessary information for your due diligence as you research the integration of Sing Core products into your project.

Homeowners or project creators ask, How Do I Get Sing Core?

Homeowners or project creators ask, How Do I Get Sing Core?

If you possess adequate woodworking and building skills, you may be able to educate yourself enough to begin your do-it-yourself Sing project. For projects like these, please contact your local lumber supply or home building center. We’ve made it easy for them to set up with us and we will ship the items that you want directly to that supplier. You can easily pick it up at their location or have it delivered to your location (if they offer that service).

Simple Way to Tell the World

Much of what we do to promote Eco-friendly Sing Core is done by word of mouth based on over-delivering affordable options in the areas of affordable lightweight and high-strength.

You can join the Sing Team by singing our song. We invite you to help us spread the word about Sing Core by joining our Referral Program and we will pay you 20% of every sale that is made through your referral link.

It’s free and a great way to help us make the world a better place together.

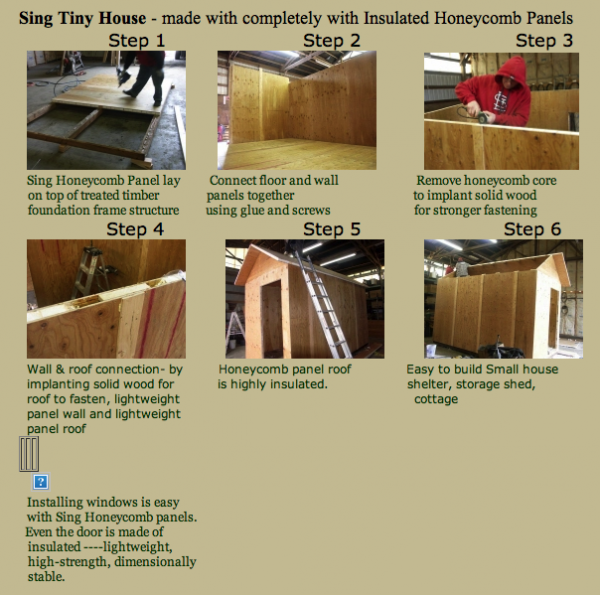

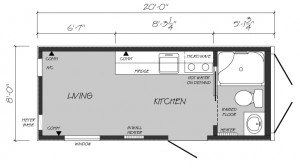

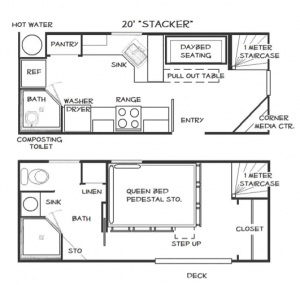

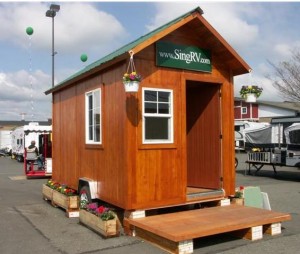

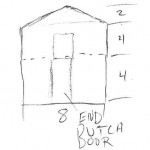

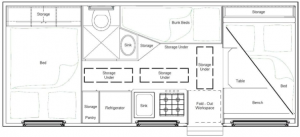

Sing Core will provide you with the materials to build a complete insulated (up to R6.5) 8 ft x 19 ft structure. We will supply windows, door, gray water tank and hinges for folding design at below cost. Structure materials will include reinforced torsion box Sing Sandwich panels with aluminum exterior surface (paintable and weatherproof) and plywood, aluminum or HPL interior walls.

Sing Core will provide you with the materials to build a complete insulated (up to R6.5) 8 ft x 19 ft structure. We will supply windows, door, gray water tank and hinges for folding design at below cost. Structure materials will include reinforced torsion box Sing Sandwich panels with aluminum exterior surface (paintable and weatherproof) and plywood, aluminum or HPL interior walls.