All Sing Core Doors are pre-insulated with sound dampening features that are enjoyed by all suppliers and end-users. This high-level of performance has increased the demand for a solution for our discriminating high-end clients to raise the bar once again in our Sing Sound Solutions.

You will find Sing Sound Doors in use in service in professional or home recording studios, voice over booths, film and television studios, broadcasting studios, instrument rehearsal booths, audiology booths, trade shows portable meeting rooms, telemarketing stations, houses of worship, government facilities and scientific testing labs.

You will find Sing Sound Doors in use in service in professional or home recording studios, voice over booths, film and television studios, broadcasting studios, instrument rehearsal booths, audiology booths, trade shows portable meeting rooms, telemarketing stations, houses of worship, government facilities and scientific testing labs.

The first generation of Sing Sound Proof Doors used lead, which is extremely heavy, and the patented Sing Core torsion-box/foam core helped address the problems associated with the weight issue, and also the softness of lead.

Without the Sing Core base material, it would be impossible to produce a true flat lead door.

In 2014, Sing Core introduces the Sing Sound Proof Door that does not have any lead content whatsoever. We have embraced new sound proof technology that meets the needs of our most particular high-end clients in the entertainment and scientific communities.

According to our clients, standard Sing Core doors are equivalent to roughly STC 30* depending on the core materials selected by the client. One recording studio engineer says, “We can build a sound-proof room, no problem. But the door… That is the weakest link. Thanks to the Sing Sound Door we have solved that problem, and are seriously considering Sing Core for use throughout the entire new studio build that we are considering at another location.”

This new generation of lead-free Sing Core Sound Proof Doors that we have made for some of our most critical clients reached higher testing ranges up to STC-56. We can help you achieve the results that you desire according to your specifications and requirements.

That said, Sing Core might be the secret ingredient of your most demanding project…

Sing Core Will Team Up With You

We work with sound engineers all the time, but we are looking to partner with someone to help us develop our sound proof line. If you have a large quantity/quality sound proof project including walls, doors, ceilings, floors, we would like to team up with you to get the job done. We have access to local sound testing facilities to achieve the higher STC rating that you desire and will share the STC rating costs with you (or totally absorb the cost if the job is big enough). Contact us for more information.

Increasingly, private and commercial accounts are seeking out Sing Core for all their sound proof needs, like sound booths and do-it-yourself sound-proofing.

1. In the Beginning…

Our adventure in sound-proofing started when our high-end door clients discovered the innate sound-deadening qualities of our standard Sing Doors, which led to the development of our Sing Sound Doors as we assisted in solving the challenges associated with elimination of excessive sound.

You will find Sing Sound Doors in use in service in professional or home recording studios, voice over booths, film and television studios, broadcasting studios, instrument rehearsal booths, audiology booths, trade shows portable meeting rooms, telemarketing stations, houses of worship, government facilities and scientific testing labs.

Sing Core provides the sound proof door solution that does not have any lead content whatsoever. We have embraced new sound proof technology that meets the needs of our most particular high-end clients in the entertainment, industrial and scientific communities.

2. How to Sound Proof a Room

Whether you’re looking to build an exotic home movie theater or a portable sound booth for street construction, we have been providing the most simple solution to sound reduction with the easiest form of delivery and construction method of all; the Sing Panel. Sing Panels have built-in structure, so that you don’t need framework, yielding you more usable space regardless of the size of your project. Every Sing Panel is imbued with sound-deadening qualities, which can be matched to your specifications. These stronger-than-steel panels are also lightweight, so that you can easily assemble your project (and disassemble, if desired or necessary) without a huge construction crew.

Whether you’re looking to build an exotic home movie theater or a portable sound booth for street construction, we have been providing the most simple solution to sound reduction with the easiest form of delivery and construction method of all; the Sing Panel. Sing Panels have built-in structure, so that you don’t need framework, yielding you more usable space regardless of the size of your project. Every Sing Panel is imbued with sound-deadening qualities, which can be matched to your specifications. These stronger-than-steel panels are also lightweight, so that you can easily assemble your project (and disassemble, if desired or necessary) without a huge construction crew.

We work with engineers, designers and upscale homeowners to create the results that they seek. We love helping to bring people’s dreams to life; we provide them with the materials they need to make their project a success, while standing by our solutions with an up to 50-year guarantee.

3. Building Your Quiet Place Can Be as Quiet as the End Result

Making your sound dream come true is as quiet to build as the end result. No heavy equipment, loud saws, sawdust or nail-pounding or even a tool-belt is required as most of your tools can be reduced to a single Allen wrench. Sing Panels are created to your specs and can easily interlock with cam-locks for a perfect fit every time. Set-up and tear-down is both quick and silent, without debris or cleanup.

It is no surprise that many industries are attracted to Sing Core due to its sound deadening properties, yet you also get the added benefits of working with a lightweight, high-strength and Eco-friendly building material. You will find Sing Sound portable recording booth solutions in use in recording studios, voice over booths, translation recording, broadcast booths, musical instrument practice booths, medical isolation booths, audiology, forensic and ballistic testing labs, etc…

4. Sing Sound in the Studio

Working with recording studios, Sing Core helps the upscale sound studio solve the acoustic challenges facing the uncompromising recording engineer with the sound isolation of the studio mic from the rest of the recording equipment.

Working with recording studios, Sing Core helps the upscale sound studio solve the acoustic challenges facing the uncompromising recording engineer with the sound isolation of the studio mic from the rest of the recording equipment.

Originally Sing Core was sought out when trying to resolve issues when faced with trying to find the answer to how to soundproof a door. It wasn’t long and the door was expanded to other applications by some of the brightest engineers and designers, because if you remove the door frame, you have a wall, lay it flat and it is a floor or ceiling.

Little is more important to the music producer than the vocal booth when recording the vocal tracks in recording studios NYC who work with the top record companies.

When working with recording studios in Chicago, Sing Core consistently solves the variety of challenges that arise from dealing with a wide variety of talent with completely customizable audio recording setups. In this specialized arena, it is more important to use the Sing acoustic sound walls as moveable and reconfigurable components for portable sound booths.

While recording studios in Atlanta presented us with providing the solutions for acoustic treatment in their rap studio in the intrinsic nature of the rap studio using Sing Sound Wall to solve the issues inherit in mixing and mastering in the sound recording process.

While recording studios in Atlanta presented us with providing the solutions for acoustic treatment in their rap studio in the intrinsic nature of the rap studio using Sing Sound Wall to solve the issues inherit in mixing and mastering in the sound recording process.

On the West Coast a record producer working with a recording studio in Los Angeles worked with Sing Core’s Sing acoustic panels in the recording studio design of their re-engineered remodel.

Whether you’re doing voice over work or mastering if you’re dealing with issues related to the recording microphone, Sing Core offers a wide variety of solutions for recording microphone isolation or pristine acoustically flat music mastering environment via our portable vocal booth or soundbooth components and/or materials.

Sound absorption issues were resolved in recording studio equipment and whisper room design in recording studios in Houston, eliminating the need for sound blankets.

5. Sing Sound Home Studio Solutions

Not to forget the countless home recording studio applications of Sing Soundboard which is available in any dimension, is easy to assemble, disassemble and reconfigure on-the-fly and stores flat so that it can be completely inconspicuous when not in use.

The home studio setup offers many opportunities to achieve the optimum high-end results from their music studio making the end product indistinguishable when compared to commercial music studios.

Among other applications, you will find collapsible small meeting rooms at tradeshows for quiet visitation between sales and new acquaintances manufactured with Sing Sound Board.

6. Home Cinema Theater Sound Treatments

6. Home Cinema Theater Sound Treatments

Helping architects provide their clients with the acoustical resources to deliver the goods when it comes to high-end home theater systems and designs is not only a welcomed challenge, but Sing Core excels in the architectural acoustics arena.

Of primary importance is to preserve the integrity of the theater look, feel and experience, while having as little impact on the other areas of the home, exterior environment and/or surrounding neighborhood.

In an effort to preserve the investment in home theatre system, care must be taken in establishing a base structure to compliment your home theater installation.

You could have the world’s best home theater system, including the home theater seating, top-drawer surround sound and décor; the last thing you want to do is to compromise the integrity of your residential theater.

You will also find the Sing Sound solution in theater architecture, acoustical wall treatments, cinema acoustics and media rooms.

7. Do-it-Yourself Sound Proofing Doesn’t Have to be Expensive

We help people create their own sound proof environment, quickly, easily and quietly, without breaking the bank. These folks simply use our Sing Panels as their base structure, then soundproof to their heart’s content. This is an effective approach to both permanent and temporary installations.

8. Temporary Trade Show Sing Sound Applications

Among the various business segments we (Sing Panels) are often invited to join our business clients as they fabricate their own trade show booths on-the-fly. Rather than relying on us (or third-party designers) they simply obtain Sing Panels as their raw materials, then build and decorate to their heart’s content.

Among the various business segments we (Sing Panels) are often invited to join our business clients as they fabricate their own trade show booths on-the-fly. Rather than relying on us (or third-party designers) they simply obtain Sing Panels as their raw materials, then build and decorate to their heart’s content.

At a trade show you want to look your best and sometimes it is important to have a professionally isolated area where you can interact with your clients without the distraction of the ongoing tradeshow noise and distractions.

You could spend top-dollar for your Sing Trade Show Booth, or simply do it yourself. All you need to do is to order the number of Sing Panels that you need to create your booth, i.e., a 12 x 8 trade show booth can be easily constructed our of seven Sing Panels (three for the back and two for each side). Your trade show booth can be assembled quickly, easily and quietly with an electric screwdriver, and can be assembled in minutes singlehandedly.

Occasionally, at an increasing rate of late, our tradeshow people have been using Sing Panels as their structure material for building on site sound proof rooms that are built rapidly at low cost.

9. Disposable Sound Proof Rooms

Here are the DIY methods that we’ve seen some of our clients build the sound proof disposable conference rooms, or presentation theaters:

Quickly assemble a number of 4 ft. x 8 ft. x 2 in. (with ¼ in. luan facing) Sing Panels into the desired room configuration.

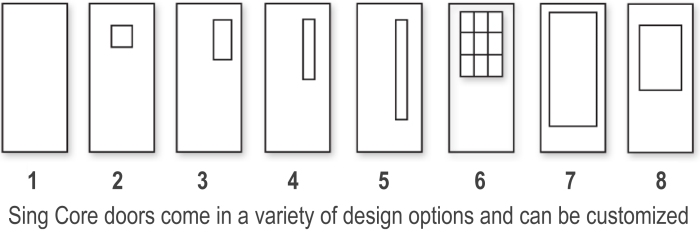

You will need a door for access. There are 3 ways to do this:

- Order 1 Sing Panels with a door (could be a Sing Sound Proof Door) built-in

- Cut a Sing Panel and insert your own door on site

- Hinge an entire Sing Panel as an access point

Using this method you will be able to assemble your private area within minutes.

Using this method you will be able to assemble your private area within minutes.

To increase sound crossover and privacy, add panels as floor and ceiling then consider how to sound proof a room:

10. The Inexpensive, Quick and Easy Way to Sound Proof Your Area

To sound proof your area, you could get Sing Sound Panels which are normally more expensive and used in permanent installations, or you could use the methods used by many of our tradeshow attendees and save thousands and thousands of dollars:

Once you have your basic Sing Panel structure assembled (including floor and ceiling) add as many layers of sheetrock to the exterior (and interior, if desired) as needed to obtain the level of sound-proofing desired.

Just have a local lumberyard deliver the inexpensive sheetrock that you need, affixing them to your existing Sing Core structure.

“How many layers of sheetrock can the Sing Panels hold?”

Remember, Sing Panels are not only lightweight and sound-dampening but they are also strong. Even without a frame (you don’t really need one because of the built-in torsion box frame) Sing Panels are many times stronger than a rinky-dink 2×4 frame and in fact are stronger than steel (see comparison). So, if you wanted to add a layer of lead for increased sound deadening, your Sing Panel frame can easily handle the extra weight.

An impressive way to increase the sound-deadening qualities of your structure is to alternate layers of sheetrock with sing panels. For example, the basic structure might be your Sing Panel core with sheet rock on both the inside and outside. On the outside add another later of Sing Panel and another layer of sheetrock to achieve the desired result.

You can also add acoustic textile, perforated acoustical soundboard or sound proof foam material to either the exterior or interior of your structure, or both.

11. Demolition of your Disposable Theater and/or Conference Room

Disassembly of your Sing Core theater or conference room is as easy as reversing the direction on your screwdriver.

Many of our economy sound-proof trade show people simply disassemble their areas, leaving the sheetrock behind for the convention center to dispose of (sometimes they even leave the Sing Panels behind, too, but most of them take the panels with them, if they can).

12. Perfect for the Do-It-Yourselfer

Think of the time and money you can save by using Sing Panels as your core structure material then have no fear in adding as much material as you want to bring your acoustic dream to life. Sing Core is strong enough to bear the weight of the heaviest sound-proofing materials, without fail. Don’t be framed, or shy, when using Sing Core.

Sound Dampening Options

We work hand-in-hand with architects, designers, sound engineers and professionals to give you the results that you desire using the products and specifications to decimate the challenges of sound absorption or sound proofing that you require.

Sing Core is not a sound proofing company, we are a specialty panel company that builds the best Eco-friendly lightweight, high-strength acoustic panels customized per your specifications for the sound proofing industry.

Note that Sing Core does not engineer STC rated doors, we only build to your architectural or engineered door specs. Be certain to detail how you want your sound door’s specifics. Sing Core can have sound doors tested and rated locally at the customer’s request and expense.

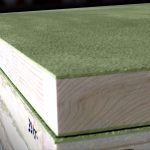

Sing Core internal options

Standard foam is EPS, common upgrade is urethane foam to increase sound deadening. Additional options include using rigid acoustic fiberglass (Armacell, ATSA, etc…) as foam replacement in the torsion box core.

Sing Panel Acoustic Skin Options

You may specify any acoustical exterior surface material that will fit the requirements of your project. Some exterior material options that we have used include: Magboard, Owens Corning 703, Knauf ECOSE® Insulation Board, Roxul Rockboard, concrete and even lead.

Additional Outer Layer Surface

Sing Acoustic Panels can be covered in a variety of additional sound absorbing acoustic materials including burlap, Guilford® of Maine acoustic fabric or any other additional outer layer surface material that is desired or requested.

How to Buy

To order Sing Sound Proof Doors submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Sound Proof Doors are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.