Applications -> Building Components -> Doors -> Technical Information

Door Panel Tech Info

Architectural Door Specifications

Handy Sing Core & Sing Panel Technical Information

Handy Sing Core & Sing Panel Technical Information

Buying wholesale Eco Logs- by buying our logs whole

Make sure the bank has experience to release the fund to you as an owner builder instead to the general contractor

Renewable and recyclable building materials—Sing home uses small diameter timber and clean wood veneer as or main ingredients of home construction materials.

Functional home—-high strength to sustained high winds, earthquake, excellent sound deadening for peace and quite, thermal mass and moisture compensation keep indoor moisture and temperature steady.

Simple and easy to build—Takes less building processes. Less management and handling, easy for average person to build, and less weight but with high strength building materials.

Dimensionally stable—-It takes less skillful labor to build and will have higher quality walls that allows coating to last. It will increase the life span of the home. It will not cause leakage due to movement of building components.

Affordable—It takes less labor for almost any person to build a fine home, Sing home building materials are lightweight, costing less to ship and ease of installation on the job site.

About how much do Sing Logs cost?

Sing Square Log costs approximately $26/sq.ft.Sing Eco Log approximately $15/sq ft.

How big are Sing Logs?

The Sing Log is about 6” thick, while the Sing Eco Log is 8-9”thick. Both are 10 ft long. The premium cedar log is more weather resistant and slightly larger than the regular log.

What makes Sing cores different from paper honeycomb trade show panels?

A: Our trade show panels use recycled eps foam and our patented vertical grain grid system, which provides much more strength and is as light/lighter than paper honeycomb.

How can I get Sing trade show panels?

A: There are three ways to order Sing trade show panels, 1) Order one or more pre-congfigured trad show display kits (easiest way, buy with one-click). 2) Build Your Own Booth. Create your own DIY customized trade show display kits using patented Sing Core trade show panel kit components, or 3) Create your own custom trade show display design and we build it to your specs using patented Sing Core inside (requires drawing).

What makes Sing cores different from paper honeycomb trade show panels?

A: Our trade show panels use recycled eps foam and our patented vertical grain grid system, which provides much more strength and is as light/lighter than paper honeycomb.

How much is a custom trade show drawing?

A: If we create the drawing for your custom trade show display the cost is $60, whereas if you attach your drawing (your drawing doesn’t have to be professional, it could be simply sketched on a napkin) to your quote request form, there is no charge for the drawing. The reason we require a drawing is so that we can know the basic shape of your structure which will help us to better quote your trade show display.

Can our company purchase only the Sing Core to make our own trade show panels?

A: The different options of our Sing Core and Sing Core Panels and our Sing Trade Show Panels allow you to decide how you want to work with our technologically advanced core material. You can choose how much or little work you want to apply to the core*. (*when applying skins you will need to use a cold-press method)

How strong are your museum panels?

A: Our Sing Trade Show Panels 4’ x 8’ x 1 3/8 standard trade show panels can support the weight of 4 people between 2 saw horses with no other support and with negligible bending.

Are significantly more water resistant than paper honeycomb museum and trade show panels.

Our Sing trade show panels come with a 10 year limited structural warranty. Limited warranty

How light are your Sing trade show panels?

A: Our Sing trade show panels are at least one-third or more lighter in weight.

How much do your Sing cores, Sing panels and Sing trade show panels cost?

What types of material can I laminate to Sing Core?

A: Any substrate (skin) that is capable of carrying a load.

How do you ship?

What is your lead time?

A: Usually four to six weeks, but this has been known to extend out to five or more weeks on occasion. For our regular contract customers, we block out production time for them and for others we will “work with them” as our production schedule allows.

How does my company become a “Regular Contract Customer”

A: You can become one of our “Regular Contract Customers” by entering into a contract to order at least 50 cores per month with our company (this allows you to receive better discounts and reserved production and shipping times)

What size are your panels?

How do we assemble a large Sing trade show display?

How much pressure to I use to apply skins myself?

A: Enough for intimate contact with our Sing Core with or without solid wood edging but too much pressure can cause damage to the core.

Do you have distributors?

A: No, at this time everything is sold directly by us from our manufacturing location in McCleary, Washington.

Do you keep any panels in stock?

A: All of our Sing Cores, Sing Panels, & Sing Trade Show Panels are made to order for each of our customers.

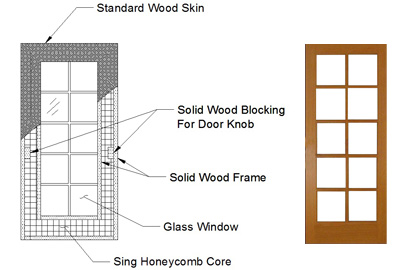

The typical houshold door is either hollowcore or made with paper core.

These doors are very weak and flimsy. Sing Core doors on the other hand can reach up to 660 psi.

This stack of doors represents one week of broken doors at a local door company. The doors are cheap to buy and cheaply made. Even worse, these doors cannot be fixed so they have to be disposed of and that is terrible for the eco-system. Sing doors do not break very easily and when they do break, they are easy to repair. You will never see a stack of Sing doors that need to be disposed of.

You will often hear about that guy that punched through his door. You will never hear of the guy that punched through a Sing Core door. Sing Doors are punch proof. We even have a punch proof challenge.

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel.

|

|

|---|---|

|

Punch proof Sing Core door.

|

Typical paper core door. (click to see more)

|

What door companies do not want you to know.

As long as you cannot see the paper core hide inside the door, they will not change it to Sing core. Sing core does not cost not much more than core made of paper but is at least 49 times stronger.

As long as you cannot see the paper core hide inside the door, they will not change it to Sing core. Sing core does not cost not much more than core made of paper but is at least 49 times stronger.

Punch through a Sing door and you will break your hand. If you can manage to punch through a Sing core punch-proof door and don’t break your hand then you will get a free sing door from us.

The most common doors used in most homes are paper core doors. With one punch you can destroy one of these flims doors. Once the door is broken you will need to take it to a door shop to get if fixed or replaced and then take it back and install it. The cost is not only a door, it is how to dispose of it, take it in and out of the shop, build or replace the door and install it. Why not just buy a Sing door to begin with. Sing doors are not much more expensive than paper core doors when consider the life span and they are free. What is your time worth?

Your door doesn’t have to be steel to be strong. Sing Honeycomb Doors are stronger, lighter and more stylish than steel and vinyl doors due to the torsion box core.

Sing Doors are more stable, insulated and lightweight than solid wood doors. The torsion box core holds the Sing Door Panel flat so that it willnot warp and sag like ordinary wood. A 16lb steel hammer will easily dent a steel or vinyl door, but not a Sing Door. Because Sing panels are efficient to produce, they are more affordable than solid wood doors.

Sing Honeycomb doors are versatile, and customizable. Even the technoly used to construct the door can cater to our customers’ individual needs.

To see more torsion box pictures and web sites visit the Google image galery.

| News Updates / Press Release |

| Youtube videos |

| Customer’s Links |

| Testimonials |

Architect

Architects Find Gold

B2B Composite Material

B2B Honeycomb Core Panel Composite Material

Composite Material of the Future

Dear Building Professional

Metal Fabrication News

Newsletter June from Sing Honeycomb

Construction

B2B Composite Material

B2B Honeycomb Core Panel Composite Material

Composite Material of the Future

Dear Building Professional

Metal Fabrication News

Newsletter June from Sing Honeycomb

The Truth About Sips

Door Manufacturer

B2B Composite Material

B2B Honeycomb Core Panel Composite Material

Composite Material of the Future

Dear Building Professional

Door Companies

Metal Fabrication News

Newsletter June from Sing Honeycomb

Sing Honeycomb Door Cores

Interior Designer

B2B Honeycomb Core Panel Composite Material

Composite Material of the Future

Newsletter June from Sing Honeycomb

Millwork

B2B Composite Material

B2B Honeycomb Core Panel Composite Material

Composite Material of the Future

Newsletter June from Sing Honeycomb

Museums

Newsletter June from Sing Honeycomb

Tiny House

Sing Tiny House program

Tradeshow Exhibitor

Newsletter June from Sing Honeycomb

Trade Show Exhibitor

Woodworkers

B2B Composite Material

B2B Honeycomb Core Panel Composite Material

Newsletter June from Sing Honeycomb

Woodworking Letter

| News Updates / Press Release |

| Youtube videos |

| Sing Core News |

Recent Customers

Hyundai Design North America, Irvine, CA

Architect

Mill Work

General Contractor

Flip Builders

Door Manufacturers

Emerald City Door

Wine Country Gardens

Arts & Entertainment & Technology

PILR

California African American Museum

Lowe Mill Arts & Entertainment

RV-Tiny House-Garage-Small Cabin

Trade show Display

Crates – Packaging – Shipping

Cecilia Story

The Nature Conservancy

“Peter and Linda along with the rest of the Sing Home team were lifesavers! They were wonderful to work with and did all that they could to meet tight deadlines without losing the flawless quality in their work. I look forward to collaborating with them again.

All the best,”

Jane

Robert Drake

“I am a returning customer of yours from last year. I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.”

Robert Drake

Robert Drake Construction:

Yes, your doors were exactly what my client was looking for and no one else in the county had them. Please feel free to give my name, cell phone number, email address and any other information you want to your potential customer. They are welcome to call anytime.

Sincerely,

Robert Drake

Robert Drake Construction

125 Year-old Church Door Replacement

These doors were replacements for original doors on our 125-year-old Church in a historic village in upstate NY. The size of the doors were quite unique, so buying premade door slabs was not an option, and custom doors were well outside of our budget. For the cost we were quoted for one set of doors, we were able to build and hang all 3 sets with the end product being a good reproduction of the original solid doors.

The Sing Core panels allowed us to get an insulated door, in our custom size, and I was able to apply 1X lumber and trim on both sides which allowed me to recreate the look of the original stile and rail look of the existing doors. The panels were straight and flat, and made a great substrate for the trim. We painted the outside in the traditional red color common on Methodist churches, and stained the inside to match to paneling in the vestibule.

Bruce

“Thanks for the follow-up, I’m very pleased with the panels an how they have worked out with my project. As you can see, I framed them with poplar molding, glued in place with waterproof glue, and painted them to seal against the weather.

I brag on these panels all the time and everyone is always impressed.

Thanks again,”

Steve

“Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.” Amy

“ I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.” Robert D.

“I love your product!” Kevin B.

—

“Your product is the bomb diggity!” Smithy D.

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Chad Thompson

Trellis Interiors

Sing Homes,

Of course, please feel free to give them my name and cell phone.

Thank you,

Chad

| DeweyWebster |

|

Cloud House |

You bet! We love your doors!!

Regards

Dewey

Direct quotes from recent customer:

What did you think of the panels when they arrived?

They looked just as I expected. High quality workmanship and to my

exact specifications.

What was it like working with them to get the design you wanted?

Very easy to work with. The panels were totally flat and square.

What did you think of the panel’s weight in comparison to their size?

Weight came in as expected which is very light compared to a solid wood

door.

Do you think that our garage door panels are equal in strength to

standard garage panels?

I think these panels are stronger than standard garage doors.

Definitely stiffer.

If you were to do another project similar to this would you buy our

garage door core panels again?

YES.

Would you tell other people where you got your door cores from?

YES.

Please tell us in your own words about your experience with our panels.

I have nothing to complain about with regards to the entire

experience. Customer service while ordering the doors was top notch.

Price was great. Shipping/delivery was easy. Fabrication of my doors

was straightforward.

-Kevin B., California

—

Thanks for getting in touch.

Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.

If you are interested, i think you could market this product to artists.

I don’t think there is anything on the market in terms of oversize drawing boards.

Thanks again.

Amy

A Testimonial from Dave Kellog – Dave Kellog is the first Sing Home customer to build in Wyoming. He’s beginning with a 24′ x 36′ multiple use cabin, and will later add a large Sing Timber residence. Dave writes:

“The project is going extremely well… the building is 24′ x 36′, and after the foundation and floors were poured, I got to wall height (10’3″) in just seven days… All work has been completed by me alone…so this has been a one person operation. I have had a lot of interested folks stop by, all very curious about the Sing Timbers. I think when I get the house and garage built, I may spec one just to see how well it sells! It has been a lot of fun so far, just like building with big Legos, and boy is this thing solid! I really like the Sing system, it is wonderful for ‘do it yourselfers’, especially if it is only yourself doing it!”

Dave Kellog

Lander, Wyoming

A Testimonial from Bob & Linda Freeman – The Freemans built two Sing Homes, a 24′ x 24′ cabin w/ garage, and a 2000 s.f. prow front home. They write:

“We built the garage/bonus room last year because our home in Bellingham was still for sale. We wanted to see if Sing Logs was what we really wanted. It turned out better than we thought it would. They are easy for people who know nothing about construction work. They look great and the logs are very strong…stronger than conventional post and beam. How do we know? We are now building the house attached to the garage and I had to cut the door opening. It was really difficult to knock the door out, even after it was cut with a chain saw! The logs also make the interior quiet, and through the winter, it was toasty warm with just a propane stove.”

Bob and Linda Freeman

Mazama, Washington

Chuck Dudley – Pioneer Home Services – I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up.

I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up in the Spring. After having built with their product, I do not want to build again using conventional framing. There simply is no comparison in quality, stability and strength, longevity, energy efficiency, or beauty. The cost is comparable to a custom stick-built home, but with so many more advantages. There is also a financial advantage with a Sing Home. As soon as the home is completed it can easily be worth more than a third more than it cost to build. Can I recommend a Sing home? Absolutely I can! I stake my reputation of 35 years in construction on the Sing Home product. Chuck DudleyPioneer Home Services

|

|

|

Here is a butcher block table top we made custom for a client, the beauty of the product speaks for itself!

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel. See our new C Series line of Affordable Barn Door and Sliding Closet Doors.

Sing Core door panels are easy to order. You may choose from our stock panels or order custom-sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day.

Sing Core door panels are available at a fraction of the price of conventional sliding door/pocket door panels. Sing Door Panels are insulated, lightweight, stronger and more dimensionally stable than solid wood panels – at less than half the price!

When using Sing Panels, you design your own door by adding the trim, paint, and hardware. Sing Core door panels are great for millwork shops and door manufacturers. Exclusive pricing is available to distributors and retailers.

Door Assembly Instructions:

Due to shipping limitations, our largest panel is 40” x 96”. However, you can combine these to make almost any size door you desire. Once your door panels have arrived, place them in the room where they will be installed and do the following:

1. Arrange your door panels on a level plane so that they can be joined precisely.

2. Join the panels in the horizontal position and applying glue in the grooved “biscuit” pocket.

3. Insert biscuit joint into one side of panel, apply glue to groove in second panel that will be attached to the first panel

4. Slide panel so that the other half of the biscuit is inserted into the biscuit groove and apply adequate pressure to the glued area. (We recommend formaldehyde-free, urethane glue)

5. Once all of the panels have been assembled together and the glue has completely dried, your Sing Core door is ready to install.

Check out the tutorial videos at the bottom of this page. Contact us if you have further questions/concerns on how to install our Sing Core door panels.

Order Custom Sizes:

To order custom door sizes, please submit a work order form. We’ll respond to you with a quote within two business days.

Step 1: Install the sliding door track.

Step 2: Prepare door for hardware installation.

Step 3: Install hardware and hang the door to make sure of fit and function.

Step 4: Finish and paint the doors.

Step 5: Admire your newly install Sing Sandwich Panel Sliding Doors.

Gallery | Technical Info | FAQ | Order Form | Standard Pricing

Title: Steam Room Door

Client: Pizza Company

Product: Sing Panels

Challenge:The client needed doors that resist moisture and close securely. He also needed the doors to withstand frequent use at a business.

Sing Solution:Sing Core doors are flat and straight enough to keep humidity from leaving the steam room. Water resistant coating was applied to protect the door, preventing it from warping and rotting.

Customer Quote:

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Title: Children’s Room

Client: Tremain Construction

Location: Washington State

Product: Sing Panels

Challenge: The family needed a large divider for their living room. It needed to be lightweight so that the kids could open and close it easily.

Sing Solution:Sing Core panels are light enough for a small child to move and easy to assemble. The family finished the doors with chalkboard paint to make it kid-friendly.

Customer Quote:

“As you can see, the photo below was taken right after install and finishing completed, still construction stuff in the area. The other picture is after the owners moved in and their kids started using the door, which is covered with blackboard paint; it becomes a moving mural in the space.” -P