Sing Core High End Giant Factory Sliding Doors Increase Productivity

Sing Core Large Factory Sliding doors can be used for all kinds of industrial purposes. They are ideal for warehouses, hangars, factories, plants, manufacturing facilities, and other industrial and commercial scenarios. Using our patented and patent pending technology, we manufacture doors that are easier and less expensive to install, lighter in weight, so they allow you to use less expensive hardware than doors made by the competition.

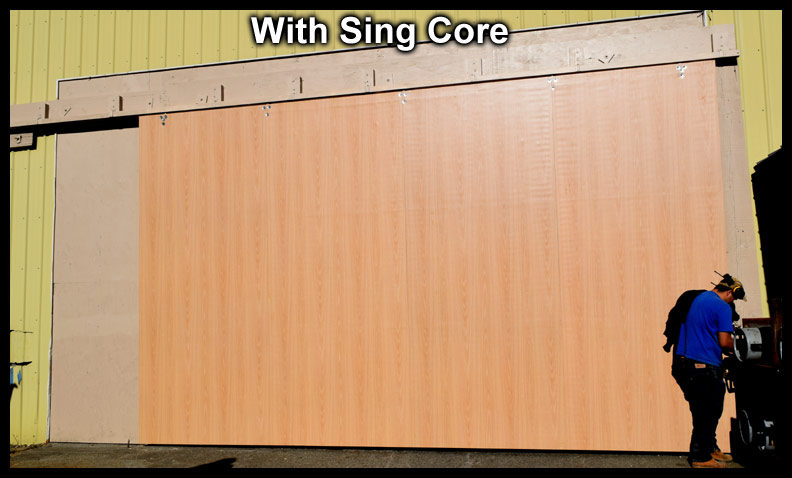

At this factory, the workers were struggling daily with their large factory door that was warping and twisting, due to environmental factors. Their door was excessively weighty and the door was extremely difficult to open and close. Door functionality was severely impaired, because of warping and twisting. It was also peeling and falling apart, due to poor construction. The managers knew they needed to fix the problem, but not just any door would do. This is why they called upon Sing Core to solve their problems.

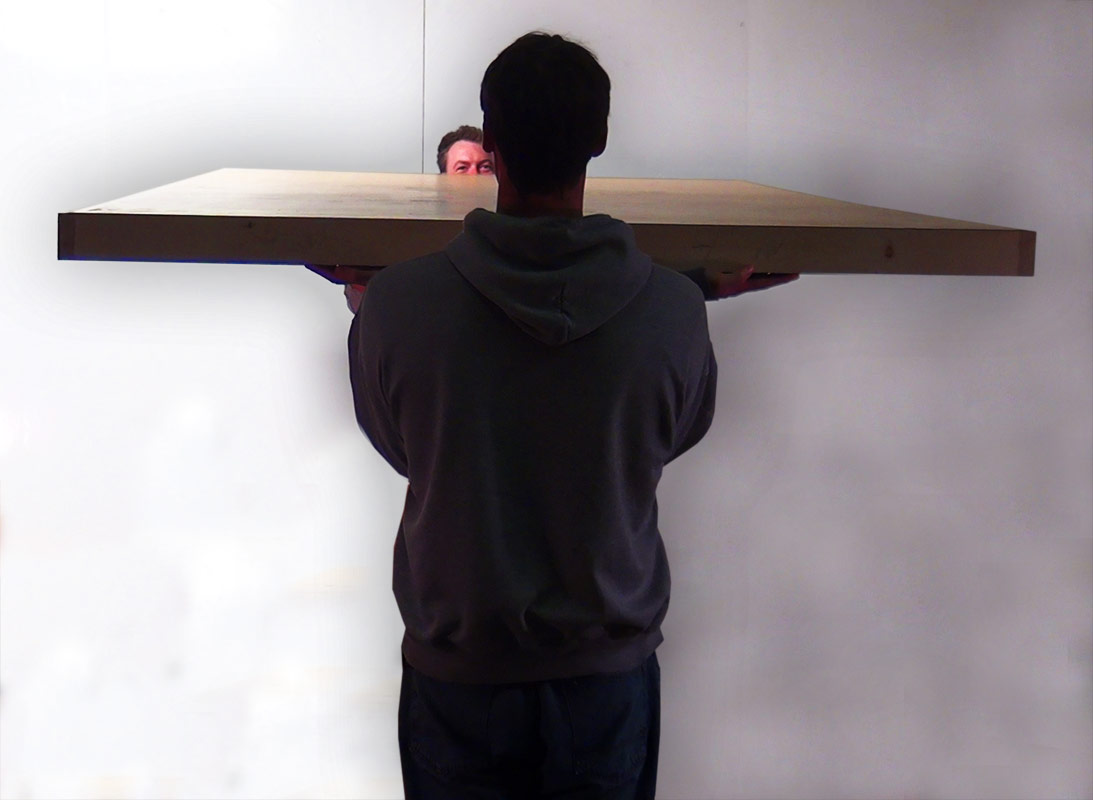

Sing Core tackled the problem immediately with their patented solutions. First of all, because of the size of the door, they knew they would need to solve the weight problem.

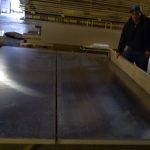

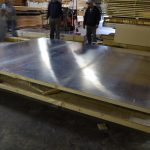

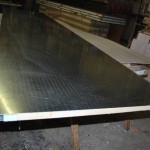

With our patented and patent pending methods, solved the weight problems. This huge panel measures 12’ x 5’ x 3” thick, yet it only weighs 121 pounds so it can be easily lifted by two men, as you can see in the photo. This demonstrates there are no other panels on the market as light and large as Sing Core panels.

The Strongest of the Strong

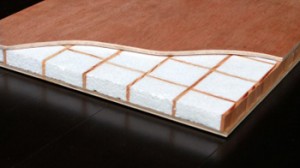

Tested independently, in UW labs, as able to withstand force upwards of 660 PSI, Sing Core, hands down, manufactures the strongest material in its weight class. Large doors need higher strength to stave off potential warpage. That’s how we provide doors that are stronger, lighter, and more warp free, according to AWI standards.

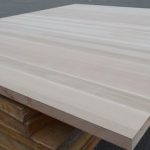

Sing Core doors also come with nearly any skin. Our most popular skins are Alder, Mahogany, Western Red Cedar, Fir, Pine, Hemlock, Balsa, Birch. Even better, we can apply hot rolled or cold rolled steel, aluminum, copper, bronze. Your doors are only limited by your imagination.

If you need the highest strength, lightest weight, most warp free large sliding doors and large pocket doors, available in more skin options than any other door, you need Sing Core doors.

This revolutionary new door has so many skins available that you will find it suits every possible purpose. You can use this door as a large factory door, a huge sliding hangar door, massive barn doors, very big manufacturing plant doors, colossal barn doors, and other magnificent bay doors that will leave your guests and customers in awe.

The Sing Core Advantage

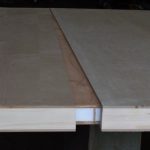

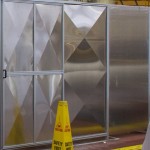

Another advantage to Sing Core is that you can apply any kind of skin or finishing. This photo shows high quality siding applied to the huge factory door. The siding is very easy to apply and is great in exterior weather conditions. Whether rain, snow, or hot sun, your door will be protected against the elements every single time.

Applying siding to your door will offer superior weather proofing.

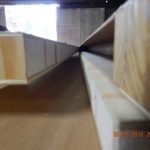

Giant factory doors are a Sing Core specialty, as you can see here from the picture, which shows how large and well built our doors are.

This photo shows the true scale of the door. When you see a full grown man standing in front of it, the massive nature of the door is apparent.

Sing Core Triple Panel Sliding Door

There are many ways to build a door. One of the most effective ways is to build multiple doors that open together in one space. There are advantages to covering your door opening with more than one panel. This allows each panel to be lighter and it offers more versatility with your hardware. Hardware does not have to be as strong, because the the weight of the full door does not rest all on one track. Also, it is much easier to install a door in sections, because very large doors tend to be heavier and much more difficult to install.

There are many ways to build a door. One of the most effective ways is to build multiple doors that open together in one space. There are advantages to covering your door opening with more than one panel. This allows each panel to be lighter and it offers more versatility with your hardware. Hardware does not have to be as strong, because the the weight of the full door does not rest all on one track. Also, it is much easier to install a door in sections, because very large doors tend to be heavier and much more difficult to install.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.