Shipping, Receiving, and Care of

Your Warp-free Sing Door

Sing Core only works with the best and most highly proficient millworks and door manufacturers. This segment of the industry is well-versed in how to deal with high-end building materials such as Sing Core. For many years, Sing Core has provided unfailing warp-free solutions to the biggest and best architects and millworks in the world, without one complaint.

As more millworks and smaller door companies are reaching out to offer their clients access to Sing Core, we do occasionally run across industry professionals who are not aware about what to expect or how to handle Sing Core raw materials. Some of these less-experienced, newer and/or smaller millworks and door companies may not know what to expect when dealing with a product like patented Sing Core. We desire to welcome newcomers to have access to patented Sing products. For those, we are providing the following information:

Unfinished

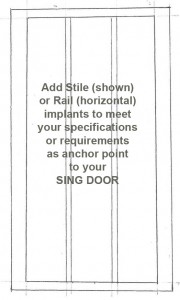

All Sing products are shipped as unfinished to the millworks and door companies who are highly proficient in working with high-end materials such as Sing Core. A Sing door blank is not a ready-to-install door and are not available from the factory with hardware or as pre-hung doors. Sing Core works in tandem with the industry professionals and the factory may, or may not, handle some of the detail works, such as applying exterior skins to the door blank. The door finishing, hardware, framing, and installation are all coordinated before your Sing door blank is built.

All Sing products are shipped as unfinished to the millworks and door companies who are highly proficient in working with high-end materials such as Sing Core. A Sing door blank is not a ready-to-install door and are not available from the factory with hardware or as pre-hung doors. Sing Core works in tandem with the industry professionals and the factory may, or may not, handle some of the detail works, such as applying exterior skins to the door blank. The door finishing, hardware, framing, and installation are all coordinated before your Sing door blank is built.

Packaging and Shipping

Sing products tend to be very large in size and require custom crating to assure they are not damaged in shipment to the industry professionals. Even with the best efforts of Sing Core’s custom crating team, sometimes a Sing product may arrive blemished and/or damaged by the shippers entrusted with the handling of crated Sing materials. In most, if not all, cases the level of structural integrity of Sing products in combination with the high level of proficiency of the finishers receiving Sing products, even damaged Sing Core can easily be returned to new condition, even if mishandled or damaged in shipment.

Sing products tend to be very large in size and require custom crating to assure they are not damaged in shipment to the industry professionals. Even with the best efforts of Sing Core’s custom crating team, sometimes a Sing product may arrive blemished and/or damaged by the shippers entrusted with the handling of crated Sing materials. In most, if not all, cases the level of structural integrity of Sing products in combination with the high level of proficiency of the finishers receiving Sing products, even damaged Sing Core can easily be returned to new condition, even if mishandled or damaged in shipment.

Arrival of Sing Products

Upon arrival of Sing products, be prepared to receive an unfinished product via truck. Offloading may require a forklift and dock for receipt. That said, there will be work that needs to be done to the product received by the millwork or door company before it is retail-ready.

Acclimatization

In most cases, when receiving a multiple Sing Core order, where Sing door blanks have been shipped in a stack, or side by side, it is perfectly normal for even a warp-free door blank to appear to be warped upon receipt. Usually, the Sing door blank(s) which face the outside of the crate, or the top of a stack of warp-free door blanks will appear to be warped. By acclimatizing these doors, they will straighten out to their straight and true flat appearance.

In most cases, when receiving a multiple Sing Core order, where Sing door blanks have been shipped in a stack, or side by side, it is perfectly normal for even a warp-free door blank to appear to be warped upon receipt. Usually, the Sing door blank(s) which face the outside of the crate, or the top of a stack of warp-free door blanks will appear to be warped. By acclimatizing these doors, they will straighten out to their straight and true flat appearance.

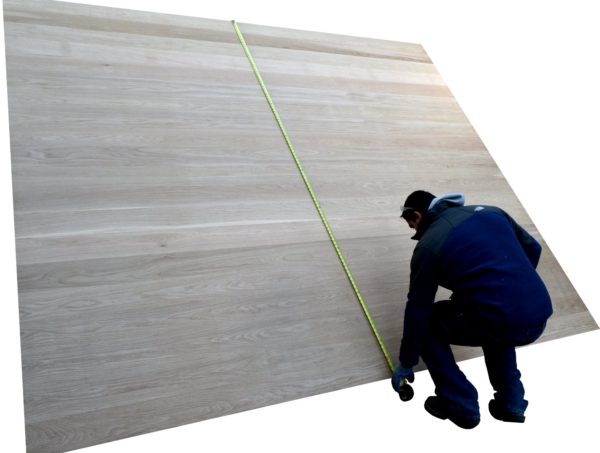

To acclimatize your Sing door core, stand your door on its edge at least twelve inches away from any adjoining surface area, allowing it to acclimate for up to 72 hours. Measure your door again and you will find it to be straight and true. If not, document for warp and contact Sing Core.

Panels must be sealed or painted before being hung to prevent warp.

Panels must be protected from weather exposure with overhang, sealing, or cladding to prevent warp.

Storage

After you’ve received your patented Sing products, in the event that you will have to store them prior to finishing and/or installation, try to store them standing upright, on end, with plenty of space in between. Do not lean Sing products against a wall. If you have to store them stacked, wrap in plastic and place one or two sheets of plywood underneath and on top of the stack of Sing products. This will help keep the entire stack similarly acclimatized while not in use, otherwise, you may have to re acclimatize the top and/or bottom Sing products later, when you are ready to use them.

Door Warp Definition

Door warp is a variation from a plane surface within the door itself. It does not refer to the door in relation to the frame or jamb in which it was hung. Bow, cup, and twist are terms which describe warp in a door and are defined as follows: Bow is a curvature along the door height, or a deviation from a flat plane from end to end. Cup is a curvature across the door width or a deviation from a flat plane from side to side. Twist is a distortion in which one corner is out of the plane of the other three corners. Warp is usually a result of unequal stresses within the door from one face to the other caused by changes in humidity and temperature conditions or uneven conditions from one face to the other. Buildings shall be humidity and temperature controlled before doors are delivered and installed. Required conditions are 25% to 55% relative humidity and 50° to 90° F (10° to 32° C) temperature range. Improper handling, stacking, and storage can also contribute to warp. Doors shall be stored flat on a level surface off the floor with cross supports.

Warp-free definition: Doors with patented professional SingCore inside outperform any other Eco-friendly door in the world in terms of being lightweight (SingCore weight is approximately 10 % of solid wood, timber or plywood core) and high strength (660 PSI+, stronger than steel pound-for-pound). No other door Eco-friendly door made in the USA can reach our high precision (SingCore approximately +/- .006 inch) or flatness meets or exceeds door industry allowance for door warp, as seen above). We guarantee no other Eco-friendly, lightweight, high-strength insulated door can compare with any door that has patented professional Sing Core inside. SingCore is raising the standard of what is possible in terms of building large doors that can be true flat and warp-free.

How can you tell if you have a warped door or not?

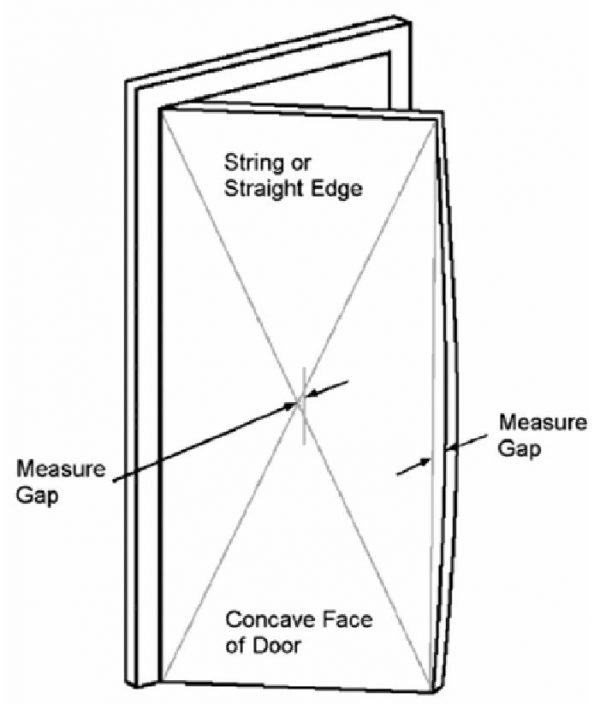

There is an industry standard method of determining whether your door is warped or not.

To determine whether you have a warped door or not you will need a length of string (longer than the length or height of your door) and a measuring stick or tape measure.

a) Tape one end of the string to the edge of the door and the other end to the opposite edge of the door.

The string should be straight. If there is a gap between the string and the door’s surface, you may have a warped door.

The string should be straight. If there is a gap between the string and the door’s surface, you may have a warped door.

b) Measure the gap between the string and the door’s surface area.

If the gap is greater than ¼” your door is warped (according to AWI standards for 1-3/8 to 1-3/4 inch doors 3’-0” to 3′-6″ x 7’-0”).

c) If the length exceeds 7 ft. AWI standard applies to any 7 ft. section. Apply string to any 7 ft. span.

Contact your door maintenance company and send them two photos.

d) [1] Photo of the length of the string which shows as much of the door in its entirety, or at least from one end of the string to the other. Then [2] a closeup photo of your measurement of the gap.

Armed with these two photographs, which can easily be emailed to the millwork or door maintenance company of your choice, the recipients will be able to determine how best to approach the repair or replacement of your warped door.

You might consider replacing your warped door with a professional door which has Sing Core inside which can be guaranteed not to warp, bend twist or otherwise fail so as to avoid this pitfall in the future.

For more information, see: Door Warping vs. True Flat

What if my door with Sing Core inside is warped?

The same standard method of determining and measuring any door with Sing Core inside is used just like any other door (as noted above).

Contact Sing Core about your concerns about your door being certain to include the two photos as noted above.

If you have purchased a professional door with Sing Core inside, you may be the recipient of a replacement Sing door.

Note that upon arrival and un-crating of a door with Sing Core inside, a door may appear warped (and indeed it will be measurable). This is normal for a door which has been packed and in transit. Stand your door on its edge at least twelve inches away from any adjoining surface area, allowing it to acclimatize for up to 72 hours. Measure your door again and you will find it to be straight and true. If not, document for warp (as above) and contact Sing Core.

In the event that a professional door with Sing Core inside is warped (which is highly unlikely) your help in determining the cause of the door’s warping is appreciated. Please assist documenting the chain of custody of your professional door with Sing Core inside, including the millwork or door company which finished the door, and the installers who installed the door, to help us insure your replacement door remains warp-free.

See Also: Sing Core Definition of Terms