Sing Core Security Doors

Sing Core Security Doors

Your front door is the gateway between your home, family, and belongings, and the outside world. Nowadays, it’s not enough to just protect your home from the elements, your door needs to provide safety and security for you as well. Sing Core’s new Security Door provides the same durable and high quality comforts you’re already familiar with, with added protection against intrusion.

What is a Security Door?

A Security Door is used to provide additional protection and peace of mind over what a standard door can do. Whether used as an exterior door, an interior door, or even a garage door, our Security Door can bring this added safety to your home or business.

Sing Core door panels are already incredibly strong, resilient, and guaranteed to last, and we stand by those qualities. However, intruders are constantly looking for ways to bypass the protection provided by traditional doors. These methods can include using anything from a chainsaw, to a circular saw, to an axe. While we trust in the strength of our standard core, with enough time and strong enough tools, even they can be cut through. With our new Security Door, that changes.

Why Choose a Sing Core Security Door?

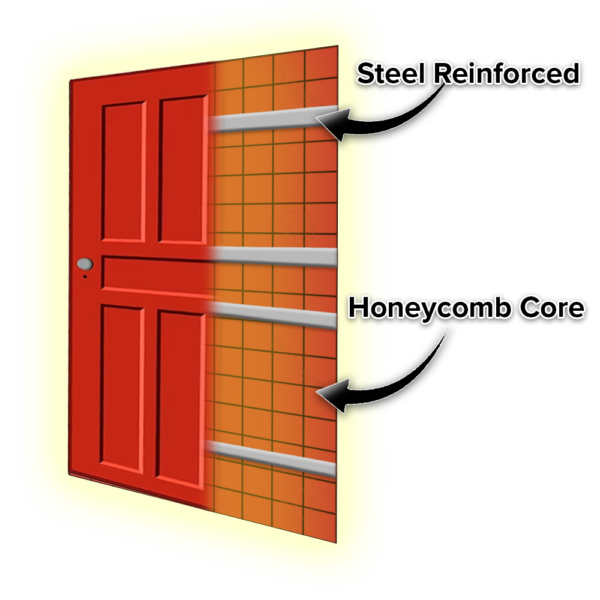

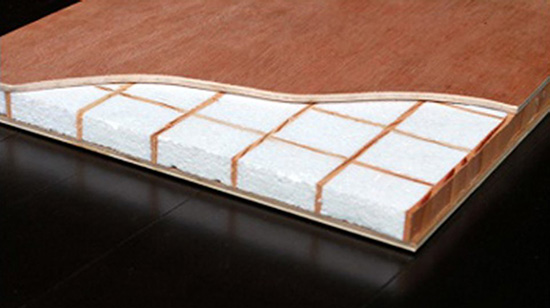

Sing Core Security Door Panels come with our patented high-quality honeycomb core and rigid steel reinforcements. The honeycomb core provides insulation, strength, and sound-deadening features, while also remaining incredibly lightweight. By adding the steel reinforcements, we double down on the strength and durability of the panel, making it incredibly difficult to cut or break through. Plus, the door remains impressively light for the quality it provides.

A traditional door can be cut through in less than a minute, and while it would often make a lot of noise, these break-ins are often done when no one is home, meaning you won’t be there to catch them in the act. Cutting through a Sing Core Security Door with the same tools would take substantially longer, and brings other challenges to the intruder, such being much louder, the likelihood of breaking a tool on the unexpected metal reinforcement, and a significantly higher chance of being caught.

In addition, these doors can be used in many cases aside from the standard front door scenario. Businesses with expensive equipment or sensitive documents may want to secure them in a more effective way, and luxury car owners may want a garage door that can’t simply be kicked in or cut through. You could even use Sing Core Security Panels to build a mobile and lightweight cabinet for on-the-go secure storage.

When it comes to your home, security is not an area where “good enough” is all you need. There are many ways you can improve the safety and security of your home, and installing a Sing Core Security Door is one of the most effective options. A break-in happens every 26 seconds in the United States, reaching 2.5 million break-ins every year, with over half being home burglaries. Let’s keep your homes and businesses off of that list.

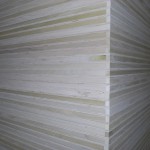

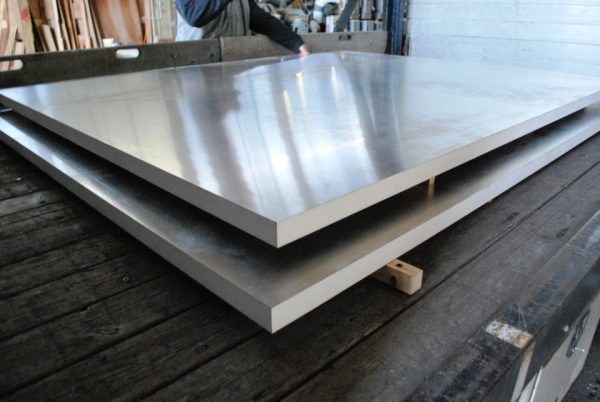

SingCore panels are engineered with a lightweight, insulated, vertical grain tension box core. Then two skins are adhered to create a panel that’s lighter, stronger, and warp-resistant. Because the strength off our core doesn’t rely on wood, which is a naturally warping material, SingCore panels have a

SingCore panels are engineered with a lightweight, insulated, vertical grain tension box core. Then two skins are adhered to create a panel that’s lighter, stronger, and warp-resistant. Because the strength off our core doesn’t rely on wood, which is a naturally warping material, SingCore panels have a