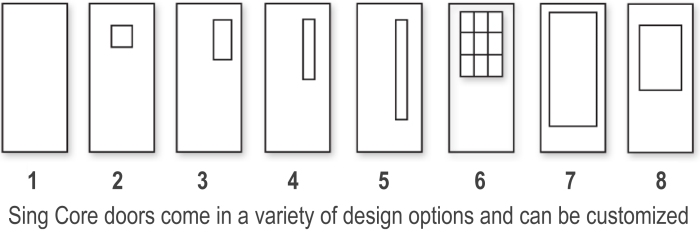

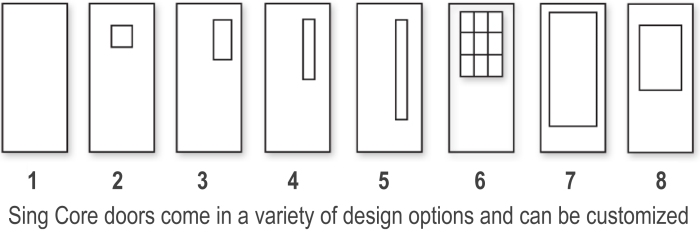

CUSTOM WINDOW CUT-OUTS – ANY SIZE – ANY SHAPE

for door professionals and manufacturers

Introducing the new, “American,” French door.

Say, “Au revoir,” to the traditional French door that limits your design options, and say, “Hello,” to the new Americanized Sing door that is nearly limitless in your creative design possibilities.

The Sing American door is basically a Sing Panel (that can be any size) custom cut for your window lights (without compromising the strength) to achieve your desired results, and can even be used to duplicate the exact appearance of any other door (and have been used in antique restorations).

The beauty of the traditional French door feature is in the greater light presence due to greater glass insertion and represents the status of traditional values. But, as you know, if you have shopped for French doors, you are limited to few options as to the placement and size of your light openings for glass.

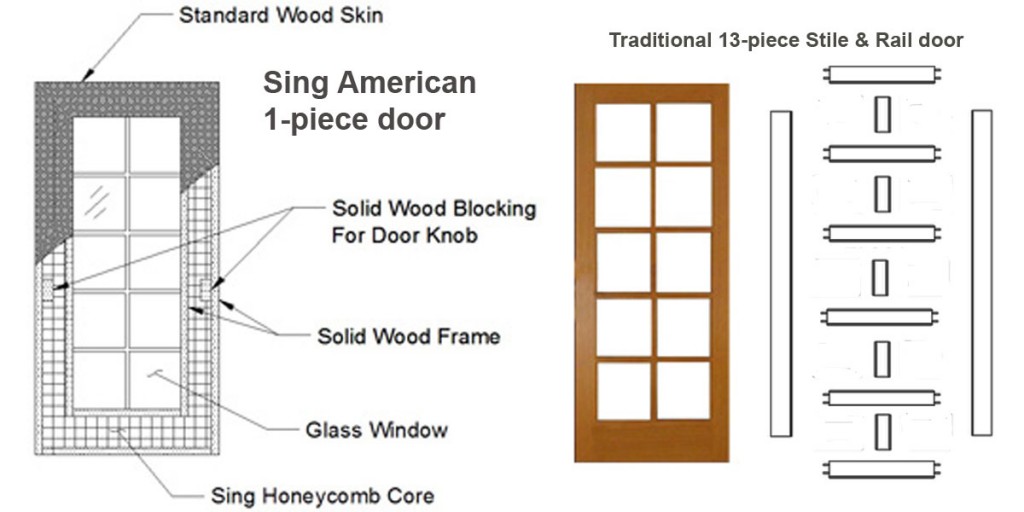

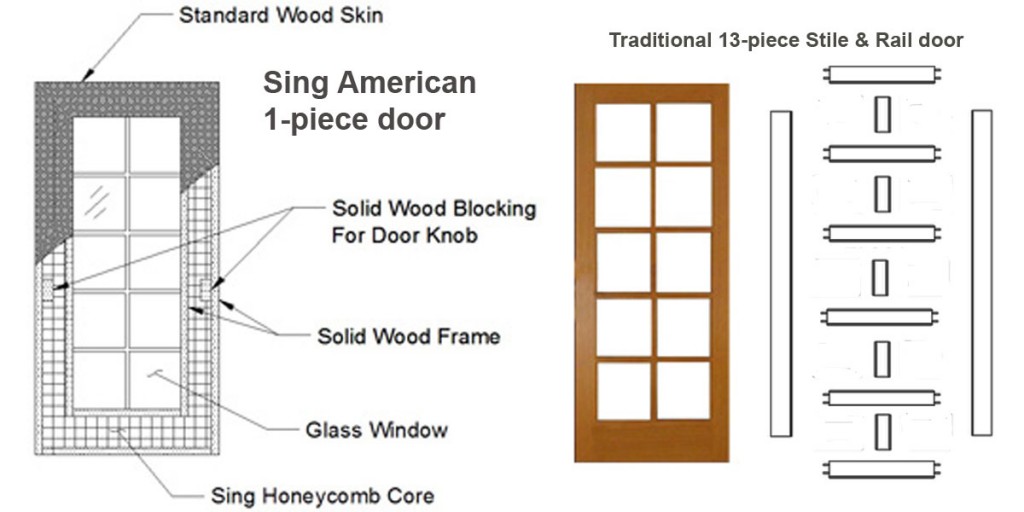

Compare Sing American Door solid one-piece design (left) to traditional 13-piece frame (right).

Up ‘til now, the only option for you, if you wanted an extraordinary French door, was to hire a high-end custom door craftsman or millwork to make your custom door to your specifications, even extremely big doors.

1 STRENGTH

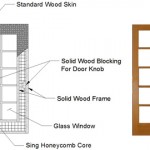

Each Sing American Door features a one-piece Sing Panel construction with window light openings cut to your specifications, then install the glass. Traditional French doors are based on stile and rail design, which makes the door weak at the four connection points and all the joints in between the glass are the weakest points of your door.

2 SIMPLIFIED DOOR MANUFACTURE

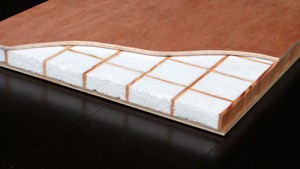

The unique one-piece Sing American Door uses patented Sing Core as the foundation of the process in contrast to conventional French glass door construction which is solid wood, stile and rail or features a sandwich panel design with foam, wood based, paper or hollow core which does not have the strength of Sing Core (one kick will delaminate other cores and they will warp, while kicking a Sing door will break your leg and can be warp-free). See core comparison used in door and many other industries.

3 COST EFFECTIVE

Custom high end doors or even regular import panel doors and French doors are created laboriously via craftsman-like intense processes. Alternatively Sing American Door require a fraction of the labor cost. You could pass these savings on to your customer or have a better profit margin by promoting high quality, long lasting true flat doors made in the USA.

4 SAFETY

Sing American Doors are lightweight. It is safer for families that have children (with precious fingers and toes). Another safety concern is due to the possible risk of injury or breakage due to kicking glass at the bottom of the door. Many designers are looking for options of reducing the glass exposure at the bottom of the door without compromising the overall appearance.

5 BE CREATIVE

Enter the Sing American Door, the door inspired by the traditional French door but allows you to have complete control of the design process. The Sing American Door is our most popular of all the Sing Doors that we manufacture.

There are many other reasons (below) that explain the advantages of Sing American Doors vs. other conventionally manufactured doors.

|

Sing American Door |

French Door |

| New Technology |

✓ |

x |

| True Flat |

✓ |

x |

| Lightweight |

✓ |

x |

| High Strength |

✓ |

x |

| Insulated |

✓ |

x |

| Sound Deadening |

✓ |

x |

| Any Size |

✓ |

x |

| 1-piece Construction |

✓ |

x |

| Custom Glass Light |

✓ |

x |

| Any Shape |

✓ |

x |

| Any Thickness |

✓ |

x |

| Any Surface Material |

✓ |

x |

| Easy Glass Install |

✓ |

x |

| Fast Turnaround |

✓ |

x |

| Eco-friendly |

✓ |

x |

A new technology for manufacturing doors – especially doors with glass – is used by all major high end millwork professionals and some leading edge door manufacturers. It starts with a patented Sing Core flush door, then cut window openings in any shape or size without compromising the strength of the door.

Sing Outside the Box

Sing Outside the Box

Embrace your creativity and let your imagination run wild!

Now you can sing with us and have your own Sing American Door customized to have glass openings custom cut to your specifications.

We see so many different and unique custom requests and styles that are unrestricted. We love enabling our clients to make their custom door dreams come true and so enjoy this creative process.

Plus, Sing American Doors have the super-strong benefits of being a solid structure without any weak connecting points to compromise your door and are resistant to warp, twist and rot over time, designed and constructed for lifetimes of maintenance-free enjoyment.

Eco-friendly Sing Doors are manufactured with our true green patented process using 92% less precious raw materials, with much less labor, energy expended and waste than any other door.

Sing American Doors come to you ready to install the glass and finishing by your door installer, or we can have the door finished for you.

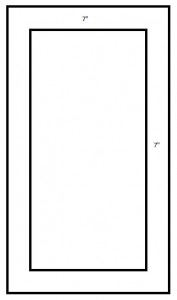

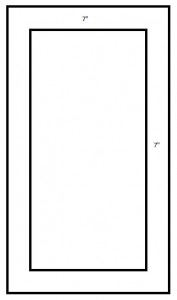

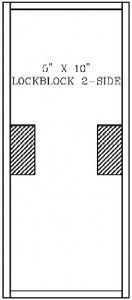

For optimal strength and resilience we suggest that you keep your window light opening locations within a 7 inch door perimeter, and you enjoy extra safety and security due to having an elegant solid door without weak spots that is fully customized by you.

The Sing American Door Secret

The secret is in the strength of patented Sing Core (click here to see Sing Core vs. other cores) that is 4-to-5 times the strength of aluminum honeycomb core used in the aviation industry. The superior compression strength (can be 700 PSI or more) and built-in insulation makes the Sing Panel the most high-performance door. Sing Core is 20-to-60 times stronger than the foam core found inside foam-core doors. A regular foam-core door is not strong enough to cut and support glass installation without reinforcement.

Doors made of Sing Core provide the possibilities of adding more trim and molding or the highest rating(s) for fire proof, bullet proof or sound deadening to build specialty doors with a designer look.

High-end Sing Doors

High-end Sing Doors

We make the most exclusive, precision high-performance door for our most exclusive clients. To achieve these spectacular results each door is custom crafted by hand. The Sing American Door is the economical alternative allowing you to duplicate the results of the custom handcrafted Sing door, saving you $1,000 or more on each door.

Sing American Doors are proudly made in the USA for you.

Any Surface Material

While French doors or doors with windows are normally considered to be wood or wood grain finished, with your Sing American Door, you can specify what material your door is made of, like aluminum, ceramic, concrete, glass, fiberglass, metals, plastics, steel, even fire-resistant mag-board and bulletproof Kevlar. So whether you are looking for an interior door with glass or an exterior door with glass, even a steel entry door with glass or any other type 1 metal door with glass, you can be certain that your door with glass insert will outperform any other door with glass insert and method. When you care to have the best interior door with glass insert, your Sing American Door with glass panels is guaranteed to be the best affordable solution.

What is a French Door?

A French door is a door style consisting of a frame around one or more transparent and/or translucent panels (called lights or lites) that may be installed singly, in matching pairs, or even as series. A matching pair of these doors is called a French window as it resembles a door-height casement window. When a pair of French doors is used as a French window, the application does not generally include a central mullion (as do some casement window pairs), thus allowing a wider unobstructed opening. The slender window joinery maximizes light into the room and minimizes the visual impact of the doorway joinery when considered externally. Often, the doors of a French window open outward onto a balcony, porch, or terrace and they may provide an entrance to a garden. (Wikipedia.)

You, our client, your dreams and desires are our priority. Let us help you achieve your American dream with your Sing American Door.

General Specifications

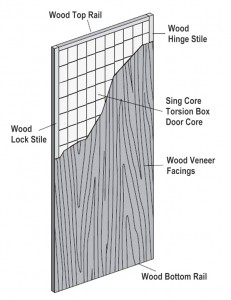

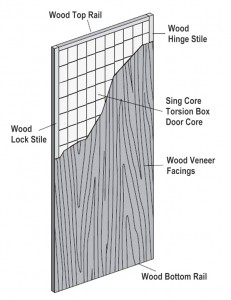

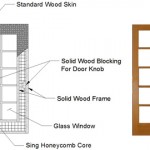

Standard Sing Core doors are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is EPS foam. Natural wood lock blocks are positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is wood framed by 1 ¾ “ natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior material (skin) according to your specifications. The default is a wood-grain (Luan) material. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Standard Sing Core doors are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is EPS foam. Natural wood lock blocks are positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is wood framed by 1 ¾ “ natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior material (skin) according to your specifications. The default is a wood-grain (Luan) material. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Click here for tips on How to Create the Right Sing Panel for your specific project.

Every Sing Core manufactured door is unfinished (unless specified otherwise) and is guaranteed for 10 years for structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core door is intended for use in:

- Single family dwelling interior applications

- Multifamily dwelling, low-rise professional office, library and low-rise motel interior applications

- Lighter use industrial building and factory, hotel and retail sales building interior applications

Product Description: 1 ¾” side-hinged door panel manufactured by Sing Core

- Door component includes paint-grade door panel only

Door Panel Materials: Sing Core doors are manufactured using Eco-friendly cold-press process. Composite materials include:

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam- Core material is framed with wood stiles and rails

- Facings are wood veneer (Luan)

- Formaldehyde-free bonding agent is used for adhesion of all components

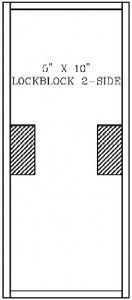

Interior Blocking: Solid wood implants are inserted as lock blocks or anchor points.

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core door from factory to your location including proper crating to protect the natural beauty of your door during transport.

Storage and Protection: Store your Sing Core door in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that door frame openings are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

- Verify that hinging and latching assemblies operate freely and correctly

Finishing: The finishing of the Sing Core standard door is the responsibility of the client due to the product being delivered in paint-grade quality unless specified otherwise in writing. Any sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary.

- Seal all 6 surfaces with two coat minimum on operable panel(s)

- Finishing or re-finishing must be completed following acclimatization and installed within 7 days

- Avoid finishing after rain (or damp) or during periods of higher than average humidity

- At least once a year, conduct periodic inspections of coating to ensure no door components are exposed

- Reseal the surface as necessary

Machining: Sing Core doors are easy to work with in the millwork shop for CNC machining or on-site for finishing, sawing, sanding, cutting and fastening. No specialized skills or equipment is necessary, other than standard woodworking tools. Treat Sing Core doors just like you would any other standard door blank.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core doors feature built-in insulation value with an R3 (can be upgraded to to R6.5 or more) rating per inch, depending on architect’s specifications.

Acoustical Performance: Sing Core standard doors have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30*. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Warranty: Sing Core manufactured doors are structurally guaranteed for 10 years under normal conditions.

Door Specifications

|

|

Door Width

|

Rough Opening Width

|

Rough Opening Height 6/8

|

| 2/0 (Single) |

26″ |

82-1/2″ |

| 2/4 (Single) |

30″ |

82-1/2″ |

| 2/6 (Single) |

32″ |

82-1/2″ |

| 2/8 (Single) |

34″ |

82-1/2″ |

| 3/0 (Single) |

38″ |

82-1/2″ |

| 4/0 (Double) |

*50″ |

82-1/2″ |

| 4/8 (Double) |

*58″ |

82-1/2″ |

| 5/0 (Double) |

*62″ |

82-1/2″ |

| 5/4 (Double) |

*66″ |

82-1/2″ |

| 6/0 (Doulble) |

*74″ |

82-1/2″ |

See also: Door Technical Information

How to Order

Simply determine the dimensions of the door you have in mind, the height, the width and the thickness. Then determine

- The external skin material

- Any internal implants required and their locations

- Any performance specifications desired

Now, you’re ready for our easy ordering process, using our online price quote.

-

-

lightweight sing honeycomb insulated door panel

-

-

-

sing honeycomb lightweight glass sandwich

-

-

non warping strong honeycomb sandwich

-

-

-

-

-

-

-

-

Insulated honeycomb sandwich door

-

-

French Doors

-

-

-

-

How to Buy

To order Sing Doors w/glass openings submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Door with wndow light openings are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.

Sing Core is committed to our strict US made pledge.

Sing Core is committed to our strict US made pledge. “We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.

“We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.