Note:

SingCore Contact Information

Office Hours: 8:30-4:30 Monday-Friday PST

Email: info@singcore.com

Phone: (360) 495-3577

Fax: (360) 495-4585

Mailing Address: P.O. Box 1691, McCleary, Washington , 98557, USA

Note:

Office Hours: 8:30-4:30 Monday-Friday PST

Email: info@singcore.com

Phone: (360) 495-3577

Fax: (360) 495-4585

Mailing Address: P.O. Box 1691, McCleary, Washington , 98557, USA

Sing Core’s Metal Fabrication Department is shaking up the industry!

Sing Core’s Metal Fabrication Department is shaking up the industry!

Our new applications are changing how to fabricate metal panels: Don’t’ Get Framed! One of our clients, I-5 Designs, has us expanding our capabilities to meet the increased demand for the longest, most beautiful aluminum panels that are eco-friendly, lightweight and stronger than steel.

Traditional metal fabricated panels expend excessive energy in their creation, using aluminum framing and the result is a panel that looks acceptable but has no strength.

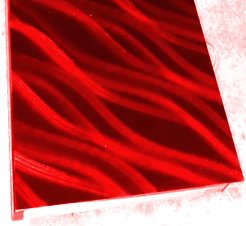

This is extremely advantageous when maintaining structural integrity over long spans… Check out this page on our web site: . You will see these 37 foot long beautiful ruby red aluminum panels that we are so proud of. Lightweight, eco-friendly, superior strength and gorgeous; you must see it to believe it.

1-2 Sing Core vs. Other Cores

1-2 Sing Core vs. Other CoresCompared to other material Sing Core is possibly the most significant Eco-friendly, renewable structural advancement in the last century increasing the strength and reducing the weight of any solid structural material.

When compared to solid material, Sing Core:

The conclusions in the following chart are based on our independent analysis. If you do not agree with any comparison results, please let us know. If you agree that these conclusions are accurate, please share this with your friends to help us build a better, more sustainable world. |

Sing Core Comparisons Based on 2″ x 2″ Grids

| Sing Core | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x |

| Solid | ✓ | ✓ | x | ✓ | x | x | x |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ |

| Oversize | ✓ | x | x | x | x | x | x |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Affordable | ✓ | x | x | x | x | x | ✓ |

| Waterproof Upgrade? | ✓ | ✓ | ✓ | x | ✓ | ✓ | x |

| Fire Retardant Upgrade? | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ |

| Bullet-proof Upgrade | ✓ | ✓ | x | x | x | x | x |

| Thickness Available | ✓ | x | x | x | x | x | x |

| Skin Options | ✓ | x | x | x | x | x | x |

| Easy to Machine | ✓ | x | x | x | x | x | x |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Even though Sing Core is less expensive than most solid material, the end result is more structurally sound, lightweight, will not compromise over time and reduces the amount of man-hours and equipment to install.

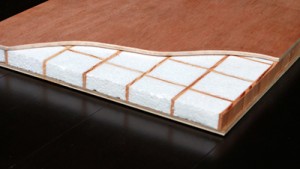

Sing Core is a honeycomb sandwich panel composite material with built in structural grids. Sing Core could have the exterior surface skin of any material including, but not limited to wood (seen in photo), metal, plastic, glass, Kevlar, even concrete and cement. The strength of our design is due to the structural grids made of naturally abundant, renewable, vertical grain veneer wood fiber. Sing Core is constructed in a fashion similar to torsion box technology most commonly found in the aeronautics and space exploration industries.

This technology is what allows our panels remain strong, lightweight, and flat without denting, cracking, and warping. See a comparison here. Inventor Peter Sing uses this torsion box technology, along with wood fiber and foam to create patented Sing honeycomb core: the incredibly strong, true flat, lightweight, renewable composite material of the future. Check out our products section to see a few different applications.

Engineering Myth-busters

Most construction is a waste of materials, natural resources and has a negative impact on our planet. Solid materials are overused in an attempt to increase the strength or lifespan of the project. This excess of materials and resources is not necessary… and can be likened to killing a fly with a machine gun.

It may be hard to believe, at first, but for the first time in our history, a truly responsible structural alternative can be found in Sing Core technology. Many of our clients were skeptical when they queried us about our lightweight and strong solutions to their design challenges.

That is why Sing Core is the secret ingredient found in the homes, offices, estates and showrooms of royalty, political and religious high-end environments. Once you try the Sing Core alternative, you will never go back to traditional building materials in some cases.

Traditional honeycomb panels have come to the rescue addressing the lightweight needs of industry. Sing Core is compatible to (if not well out-performing) most honeycomb technology in terms of weight, but no other honeycomb core can compare to Sing Core in terms of strength. None.

Before today, you did not know about Sing Core’s environmentally responsible solutions to function and sustainability. Now that you do, what will you do with that knowledge?

Take the Sing Core challenge.

install Sing panel, post and beam products are much easier than conventiaonl solid material. It is lighter in weight, high strength, true flat. It is safe for worker handle lightweight but sturdy material especially certain job site require heavy lifting, and hard to reach high rise work place.

Sing panel and post and beam have solid edge and solid wood implant if necessary at any desire location. It could machine drill, fastening sanding and cutting like solid material, according to the design of solid wood preinstalled.

Why Sing Core is “True Green” Technology

|

Why Sing Core veneer structure is “Green” and the most earth friendly way to use natural and manmade materials? Many people ask… “Is the foam used in Sing honeycomb core a green product?” The answer is yes when looked at in terms of sustainability. The life cycle assessment (LCA) is emerging as the accepted way to determine the true environmental impact of any product. LCA provides a “cradle to grave†measurement of a product’s environmental impacts from raw material extraction and manufacturing through distribution, use, maintenance, and disposal. A good example that we are all familiar with is a coffee or tea cup made of Styrofoam or a coffee mug made of same material but enclosed in a solid container. Solo cups are only used once than thrown away as garbage to fill our land fill. But the same solo cup material made into a permanent coffee mug could last 10 years without being replaced. You will agree that the same materials use, life span, and impact on the environment are the way to judge green and non green. The cost of solo eps foam cup is not only how much you spend for 10,000 cups during 10 years of time. (Assuming: 3 times a day x 365 days, times 10 years = 10,000 solo cups to the land fill from one person.) ——- But the total cost is the energy to produce, ship raw materials, and disposal. LCA studies show that wood is better for the environment than steel or concrete in terms of embodied energy, global warming potential, air emissions, water emissions, and solid waste production. Sing Honeycomb core structure is made of 100% natural vertical grain wood veneer. This sets us apart from our counterparts who use paper, particle board, aluminum, and plastic.  Furniture made of honeycomb can last 10 times or longer than furniture made of paper honeycomb, and particle board. If the price of Sing Core furniture is divided by 10, it will be the most economic furniture on the market today. If you consider the life span of these products than you will agree Sing honeycomb is the answer for green products. Sing honeycomb products are made of recycled foam, and 100% clean wood veneer. Sing honeycomb reinforces, reduces the weight and replaces the high energy consuming materials such as wood, plastic, metal, fiberglass, and concrete with minimum impact to the earth. The following is the energy consumption comparison of sing honeycomb vs. wood, and wood vs. the other man made materials for your reference. The energy consumption of wood products vs. others: The energy required to produce one ton of wood is much less than that for other materials. Compared to the energy required to produce a ton of wood, it takes: 5 times more energy to produce 1 ton of cement 14 times more energy to produce 1 ton of glass. 24 times more energy to produce 1 ton of steel. 126 times more energy to produce 1 ton of aluminum  Sing honeycomb vs. wood, —— Sing honeycomb only has 10% or less of wood and almost 90% of air. It is the strongest lightweight, renewable material made of vertical grain natural wood veneer fiber. Products made of Sing honeycomb core are the strongest lightweight renewable products available at a low cost. Deciding if a product is “Green” should be based on the Life Cycle Assessment and energy consumption required to produce, transport, and dispose. This is why Sing Honeycomb is a truly “Green” product. Facts about Polyurethane Foam

Rigid polyurethane and polyiso products deliver a unique combination of properties, as described below. Energy Efficiency

High Performance

Versatility

Thermal/Mechanical Performance

Environmental

Rigid polyurethane and polyiso foams contribute to society and culture by conserving resources. Their ideal properties exceed those of any comparable material in strength-to-weight ratio, R-value and durability, while their versatility enables builders to use them for dozens of different applications, each yielding high performance and exceptional energy efficiency. Click Here to read article written by Green Builder Magazine |

|

1) Our environmentally friendly honeycomb structure is made of 100% vertical grain wood veneer. This is the foundation for the strength of our panels. The close up image of the vertical grain wood veneer material is what makes up our honeycomb core. Honeycomb Core – This is the strongest, lightweight, affordable, earth-friendly honeycomb core ever invented. Sing wood veneer honeycomb core takes less energy to produce than other honeycomb cores such as aluminum, plastic, and paper.

2) Rot Resistant – Sing Panels and Beams are rot resistant even with ground contact. They can withstand extreme moisture and humidity. Sing Panels and Beams are also able to withstand extreme dryness and heat. |

|

|

|

3) High Strength – Sing Panels are the strongest and stiffest insulated wood panels in the world. The strength of Sing Panels is unmatched. Sing Honeycomb Core Concrete home building system. It is the strongest lightweight insulated low cost home in the world—-We prove our claim by the picture below and to the right. $1000.00 dollar reward if you can prove otherwise. Pictured to the right is a one ton truck on a piece of 1/4″ inch thick Hardy Plank wrapped around our Honeycomb core. it does not crack under the pressure of a 1 ton truck. This is the future economical, concrete home structure. The picture is proof. Can you drive a 1 ton truck over a conventional frame home wall without it cracking??

|

The picture above shows a 2 inch paper honeycomb panel failing.

The above picture shows a 1 3/4 inch Sing Wood Veneer Honeycomb panel with a heavy load resting on the top. |

|

|

4) Flat and Straight – Sing Panels and beams are manufactured to be the most flat and straight. When force is applied to a panel its performance is measured in stiffness and deflection (How much it bends.) Sing Panels stiffness and deflection properties exceeds current panel manufacturing requirements for performance.

|

|

|

|

5) Lightweight – Sing Super Honeycomb Panels and Beams are the lightest and strongest, earth friendly, affordable, honeycomb structures on the Market.

|

|

|

|

6) Sound Deadening Properties – Sing insulated wood panels offer unsurpassed sound deadening properties. This ensures that you can enjoy the quiet solitude of your home or cabin. Experience the quiet, calm in your home even during a storm with Sing Insulated Paneling.

|

|

1) Are Sing Panels like other honeycomb core panels?

· Only in appearance. Other honeycomb panels do have a grid system, but generally the grids are left empty.

· Sing Panels feature vertical wood grain torsion box to form the grids. The voids are bonded and filled wall-to-wall with resilient recycled foam (a variety of foams are available to meet your specifications).

· Only Sing Panels are solid as a rock. (Warning: Do not kick a door made with a Sing Panel, you will break your leg before you break the door.)

2) What is the R-value of the Sing Panels?

· The R-Value of Sing Panels using EPS Foam is 3.5 per inch. The R-value of Sing Panels using Urethane Foam is 6.5 per inch.

3) How strong are Sing Panels?

· Very strong. In fact, they are the strongest affordable lightweight building material.

· They have been independently tested by the University of Washington to exceed 660 PSI, and can be custom designed to achieve over 1,000 PSI per your specifications.

4) Do Sing Panels have solid wood edges?

· Yes. Sing Panels feature solid wood (or other solid material) edges. If solid edges are not necessary, consider Sing Sandwich panels.

· The wood edge is visible between the exterior surfaces (or “skins”) on the edges. Edge-banding is available at extra charge.

5) What surface materials are available for Sing Panels?

· Our standard surface material is Luan (lightweight plywood).

· Sing Panels are available in basically any flat exterior building material and is limited only due to availability.

6) What thicknesses are available?

· Standard thickness of Sing Panels are 3/4 inch to 8 inches thick.

· Custom thicknesses are available to meet your required specifications, up to 12 inches and beyond.

7) How big can you make Sing Panels?

· Standard sized Sing Panels are 4 ft. x 8 ft..

· They are available in any dimensions, up to 22 ft. by 40 ft. or larger.

· Note: When ordering oversized Sing Panels be certain to confirm that the panels that you order will meet your performance specifications.

8) Are Sing Panels weather resistant?

· Sing Panels are lightweight, high strength and weather resistant only to the degree of the surface material.

· Sing Panels can be manufactured to withstand the most extreme weather conditions, and are even used in underwater applications (consult with Sing sales staff prior to ordering waterproof Sing Panels).

9) Can Sing Panels resist the heat of powder coating?

· Yes. Sing Panels can be designed and manufactured to withstand the heat of powder coating.

10) Can I bond other materials to the surface of Sing Panels?

· Yes. Many of our high-end millworks adhere other surface materials to Sing Panels when used as substrate.

· Standard Luan (lightweight plywood) surfaces are easily adhered to with regular carpenter glue and cold-pressed.

· If your intention is to laminate other materials to your Sing Panels, you should check with us first, to make sure that you are using the proper bonding agents) to achieve the results you desire..

11) Can I use Sing Panels to make furniture?

· Yes. In fact many leading edge furniture manufacturers are joining the Sing Panel revolution. See: Sing Furniture.

12) Can I hot press Sing Panel?

· Yes. We just finished up a 40 run of hot-press veneer for one job. Tip: When using a wood veneer, some warping could occur. Our expert staff encourages adding a thin later of aluminum between the core and the skin.

Sing Core mission statement: To make life easier, Sing Panels are simple to build with, simple to use and are built to last and this makes them beautiful, so Simple is Beautiful.

1-1 Making the world a better place

2-1 Sing core

2-3 Sing panel

3-1-1 Door

3-1-1-1 Sliding door

3-1-1-1-1 Barn door

3-1-1-1-2 Cold storage sliding

3-1-1-1-3 Glass sliding door

3-1-1-1-4 Sliding pocket doors

3-1-1-1-5 Sliding door hardware

3-1-1-2 Large oversize doors

3-1-1-2-1 Large oversize sliding door

3-1-1-2-2 Large aluminum doors

3-1-1-2-3 Large aluminum/wood composite

3-1-1-2-4 Large oversize custom doors

3-1-1-2-5 True flat oversize door

3-1-1-3 Standard size door

3-1-1-4 Exterior door

3-1-1-5 Interior door

3-1-1-6 Flush door

3-1-1-7 French door

3-1-1-8 Carriage door

3-1-1-9 Overhead garage door

3-1-1-10 Pivoted door

3-1-1-11 Painted door

3-1-1-12 Wood door

3-1-1-13 Aluminum door

3-1-1-14 Metal door

3-1-1-15 Steel door

3-1-1-16 Fiberglass (FRP) door

3-1-1-17 Ceramic door

3-1-1-18 Cement board door

3-1-1-19 Bi-fold door

3-1-1-20 Sound proof door

3-1-1-21 Truck door

3-1-2 Floor

3-1-2-1 Wide plank floor

3-1-2-2 Large floor panels

3-1-2-3 Ice hocky and ice skating event floor

3-1-2-4 Portable

3-1-2-5 Raised floor

3-1-2-6 Lightweight high rise commercial floor

3-1-2-7 Stage floors

3-1-2-8 Mezzanine floors

3-1-2-9 Clean room floors

3-1-2-10 Temporary industrial floor

3-1-3 Walls

3-1-3-1 Wall panel

3-1-3-2 Structure insulated panel wall

3-1-3-3 Rain screen wall

3-1-3-4 Curtain wall

3-1-3-5 Aluminum insulated panel wall

3-1-3-6 Modular office wall, partition wall

3-1-3-7 Aluminum insulated panel wall

3-1-3-8 Museum display walls

3-1-3-9 Movable walls

3-1-3-10 Recording studio walls/Sound booths

3-1-3-11 Elevator wall panels

3-1-3-12 Whiteboard walls

3-1-3-13 Sound proof walls

3-1-4 Ceiling

3-1-4-1 Cloud ceiling

3-1-4-2 Ceiling

3-1-5 Roof

3-1-5-1 Roof structure/Sing beam

3-1-5-2 Roof/Sing timber truss

3-1-6 Window frame

3-1-7 Out door structure

3-1-7-1 Storage unit

3-1-7-2 Out door deck

3-1-7-3 Stepping stone

3-1-7-4 Portable garden concrete floor

3-1-7-5 Out door furniture

3-1-8 Stair

3-1-8-1 Wood stair tread

3-1-8-2 Metal stair tread

3-1-8-3 Cement board,concrete Stair tread

3-1-8-4 Rail for stair

3-1-8-5 Wood stair tread

3-1-9 Post and beam

3-2 Museum, trade show, store fixture

3-2-1 Whiteboard & magnetic white boards

3-3 Signs

3-3-1 Signs aluminum

3-3-2 Signs wood

3-3-3 Signs concrete

3-3-4 Signs plastic

3-3-5 Sign graphic displays panels

3-4 Transportation

3-4-1 Deck, wall, door for truck and train

3-4-2 Elevator

3-4-3 RV

3-4-4 Aviation

3-4-5 Marine

3-4-6 House Boat

3-4-6-1 Flooring

3-5 Industry

3-5-1 Cold storage

3-5-2 Equipment enclosure

3-5-3 Mezzanine

3-5-4 In plant building

3-5-5 Clean room booth

3-5-6 Dunnage

3-5-7 Sheet good 4 ft x 8 ft Sing panel holding tray

3-5-8 Shelf

3-5-9 Rack

3-5-10 Cart

3-5-11 Pallets

3-6 Sing furniture

3-6-1 Bed room

3-6-1-1 Dressers

3-6-1-2 Armoires

3-6-1-3 Captain bed

3-6-1-4 Bedframes

3-6-1-5 Night stand

3-6-2 Living room

3-6-2-1 Bookcase

3-6-2-2 Bookshelves

3-6-2-3 Entertainment center

3-6-2-4 Shelf storage / shelving

3-6-3 Dinning room

3-6-3-1 Dinning table

3-6-3-2 Folding table

3-6-3-3 Bench

3-6-4 Kitchen furniture

3-6-4-1 Island center

3-6-4-2 Butcher block table

3-6-4-3 Butcher block

3-6-4-4 Cutting board

3-6-4-5 Kitchen cabinet

3-6-4-6 Vanity

3-6-4-7 Island Cart

3-6-5 Garage

3-6-5-1 Out door furniture

3-6-5-2 Folding table

3-6-5-3 Picnic table

3-6-5-4 Work bench

3-6-5-5 Closet organizer

3-6-6 Tables

3-7 Institution

3-7-1 Schools

3-7-2 Church

3-7-3 Medical

3-7-4 Judicial

3-7-5 Military

3-7-6 Mass media

3-7 Hospitality

3-7-1 Hotel, motels and resorts

3-7-2 Restaurant and bars

3-7-3 Travel and tourism

3-8 Sing Log home

3-8-1 Sing eco log

3-8-2 Sing log

3-8-3 Sing log post and beam

3-9 Sing Tiny house

3-10 Panelized home

3-11 Sing post and beam home

3-12 Aquatic

3-12-1 Pool cover

3-12-2 Ground swimming pool

3-12-3 Water tank

3-13-4 Hot tub

4-1 Homeowners

4-7 Distributors

7-1 Q and A

7-2 How to

7-4 Tech info

7-5 Miscellany

7-5-1 Metric Conversion

7-5-2 Warranty

7-5-3 Sing Product Catalog

8-1 News

8-2 Gallery

8-3 Video