1-1 About Sing Core

We humbly agree with industry professionals that we build the best doors, walls, floors, ceilings, roofs, carriage doors and tiny houses.

The truth is that we supply the unfinished components to the artists, designers, manufacturers, builders and craftspeople that make our product look so good. While Sing Core is associated with the most beautiful and ornate end products it is the artist who makes us look so good when our applications are revealed.

We supply the core material that makes the high performance of the end product possible by providing the artist with an Eco-friendly, lightweight base that is high-strength on which to build their creations resulting in dreams being realized.

In this regard, Sing Core is more comparable to a plywood manufacturer that supplies a craftsman with the raw materials necessary to create their works of art.

Except for a few items that we sell retail, our function is in the wholesale delivery of this high performance material directly to the millworks and manufacturers.

On vary rare occasions we cooperate directly with an end-user for a highly customized one-of-a-kind creation/solution but this is extremely rare and costly.

SingCore is the strongest lightweight, earth friendly, low cost material with endless applications. With SingCore honeycomb panels you can build strong, lightweight, environmentally friendly products that are true flat and stay flat. Potential applications include furniture, concrete tables, truck bodies, boats, and airplanes. The possibilities are endless. Sing core products have built an entire home (click here) from floor to roof. A Sing home is the strongest, lightest weight, most energy efficient home in the world. We serve the best companies in major markets from coast to coast who seek out our specialized services when faced with particular challenges in design and building. Due to Sing Core’s patented design, it is the only Eco-friendly material that is lightweight, stronger than steel pound for pound with the unique ability to remain straight and true flat over long spans, even under stress, and can stay flat for centuries. If you’re not currently using Sing Core, maybe your should contact us so that you can become one of our clients.

Sing Core is proudly made in the USA and is the only patented structural composite material that comes with a limited lifetime warranty. See: testimonials

1-2 About the Inventor

Make the World a Better Place

When Peter Sing was a teenager, he learned about the properties of the honeycomb structure from the aluminum honeycomb used in aircraft. It was very lightweight and high strength material but was expensive to produce because of the energy consumed in the manufacturing process. Peter worked to invent a honeycomb material that used renewable resources and a low-energy process to produce a low-cost, high-strength honeycomb building material. This is how a life time of invention started – and now, after 30+ US and International patents, SingCore Honeycomb Products have become the best combination of natural materials and human ingenuity you will find on the market today.

Wood is next to earthen material as the most commonly used building material on our planet. Grown naturally for millions of years, humans started to use wood in the construction of their shelters after they moved out of caves. For thousands of years our ancestors cut natural wood to build furniture and construct shelters. Later, engineered wood products started to replace solid wood: laminated wood, plywood, chipboard, OSB (oriented strand board), and the list goes on.

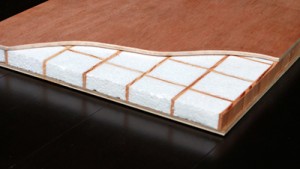

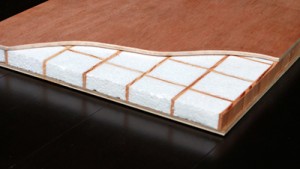

The invention of the Sing Honeycomb process is based on very simple idea: it takes less wood fiber to provide the same strength as solid wood, and with a better insulation value. Imagine taking 100% of the wood fiber out of the solid wood and reintegrating 10% of that wood fiber into vertically structured foam arranged in geometric shapes. The honeycomb core material is made of thin wood veneer, which is the main component of plywood, surrounding an insulated and sound-deadening foam base material. The implanted vertical grain veneer is composed of high strength wood fiber . This unique torsion box technology yields the strongest, lightest weight, fully insulated for block heat and sound low-cost, long lasting material ever created with natural materials.

Helping the homeless

When Peter Sing thought of the invention of Sing Core, he also put the homeless in mind. With help, Sing Core can help homeless families by providing tiny house kits to help these families with privacy and shelter in their hard times. If you would like to help click here to learn more about what you can do to help.

See: Sing for the World to help battle housing and economic struggles at home and abroad

Peter Sing President Sing Square Log Homes P.O. Box1691 McCleary, WA 98557 (360) 495-3577 www.singcore.com

1-3 Sing Core vs. Other Cores

Compared to other material Sing Core is possibly the most significant Eco-friendly, renewable structural advancement in the last century increasing the strength and reducing the weight of any solid structural material.  The invention of Sing Core is a hybrid technology fusing the positive attributes of Balsa wood (only 8% of natural wood fiber) and foam core (recycled) into the revolutionary new building material that is changing the way construction impacts our world. When compared to solid material, Sing Core:

The invention of Sing Core is a hybrid technology fusing the positive attributes of Balsa wood (only 8% of natural wood fiber) and foam core (recycled) into the revolutionary new building material that is changing the way construction impacts our world. When compared to solid material, Sing Core:

- uses less solid material

- environmentally sound

- structurally stronger

- lasts longer

- less expensive than most solid material

- easier to work with

| The conclusions in the following chart are based on our independent analysis. If you do not agree with any comparison results, please let us know. If you agree that these conclusions are accurate, please share this with your friends to help us build a better, more sustainable world. |

Sing Core Comparisons Based on 2″ x 2″ Grids

|

Sing Core |

Foam |

Aluminum |

Balsawood |

Nomex |

Plastic |

Cardboard |

| Insulation |

✓ |

✓ |

x |

x |

x |

x |

x |

| Sound Deadening |

✓ |

✓ |

x |

x |

x |

x |

x |

| Lightweight |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

x |

| Strength |

✓ |

x |

✓ |

✓ |

✓ |

x |

x |

| Solid |

✓ |

✓ |

x |

✓ |

x |

x |

x |

| Eco-friendly |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Renewable |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Oversize |

✓ |

x |

x |

x |

x |

x |

x |

| Dimensionally Stable |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

| Affordable |

✓ |

x |

x |

x |

x |

x |

✓ |

| Waterproof Upgrade? |

✓ |

✓ |

✓ |

x |

✓ |

✓ |

x |

| Fire Retardant Upgrade? |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

✓ |

| Bullet-proof Upgrade |

✓ |

✓ |

x |

x |

x |

x |

x |

| Thickness Available |

✓ |

x |

x |

x |

x |

x |

x |

| Skin Options |

✓ |

x |

x |

x |

x |

x |

x |

| Easy to Machine |

✓ |

x |

x |

x |

x |

x |

x |

| Fast Turnaround |

✓ |

x |

x |

x |

x |

x |

x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

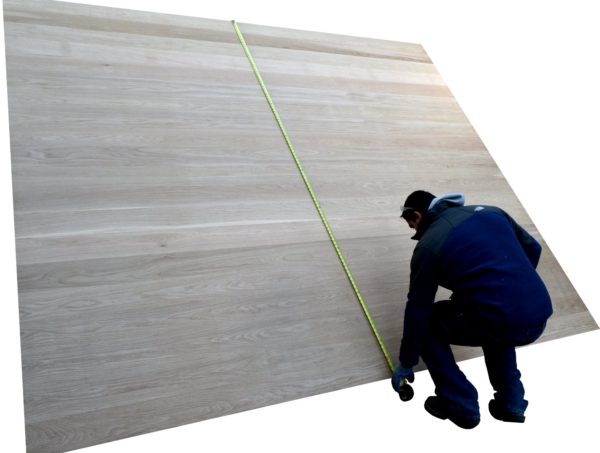

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Even though Sing Core is less expensive than most solid material, the end result is more structurally sound, lightweight, will not compromise over time and reduces the amount of man-hours and equipment to install. Sing Core is a honeycomb sandwich panel composite material with built in structural grids. Sing Core could have the exterior surface skin of any material including, but not limited to wood (seen in photo), metal, plastic, glass, Kevlar, even concrete and cement. The strength of our design is due to the structural grids made of naturally abundant, renewable, vertical grain veneer wood fiber. Sing Core is constructed in a fashion similar to torsion box technology most commonly found in the aeronautics and space exploration industries. This technology is what allows our panels remain strong, lightweight, and flat without denting, cracking, and warping. See a comparison here. Inventor Peter Sing uses this torsion box technology, along with wood fiber and foam to create patented Sing honeycomb core: the incredibly strong, true flat, lightweight, renewable composite material of the future. Check out our products section to see a few different applications. Engineering Myth-busters

- Heavy is not equivalent to strong

- Lightweight is not equivalent to weak

- Expensive material does not ensure high function

- Solid material is overused and not ecologically responsible

Most construction is a waste of materials, natural resources and has a negative impact on our planet. Solid materials are overused in an attempt to increase the strength or lifespan of the project. This excess of materials and resources is not necessary… and can be likened to killing a fly with a machine gun. It may be hard to believe, at first, but for the first time in our history, a truly responsible structural alternative can be found in Sing Core technology. Many of our clients were skeptical when they queried us about our lightweight and strong solutions to their design challenges. That is why Sing Core is the secret ingredient found in the homes, offices, estates and showrooms of royalty, political and religious high-end environments. Once you try the Sing Core alternative, you will never go back to traditional building materials in some cases. Traditional honeycomb panels have come to the rescue addressing the lightweight needs of industry. Sing Core is compatible to (if not well out-performing) most honeycomb technology in terms of weight, but no other honeycomb core can compare to Sing Core in terms of strength. None. Before today, you did not know about Sing Core’s environmentally responsible solutions to function and sustainability. Now that you do, what will you do with that knowledge? Take the Sing Core challenge.

1-4 Environment & Energy Friendly

How is Sing Honeycomb “Green”

1 Sing Core – the most earth-friendly way to use natural renewable materials Sing Honeycomb core structure is made of 100% natural vertical grain wood veneer. This is what sets us apart from our counterparts who use honeycomb core materials such as paper, particle board, aluminum, and plastic. Here at Sing Honeycomb, environmentally friendly construction is our mission.

2 LCA (Life Cycle Assessment) Sing Honeycomb strives for a “cradle to grave” measurement of a product’s environmental impact from raw material extraction and manufacturing through distribution, use, maintenance and disposal. An obvious example is a coffee cup made of styrofoam compared to a coffee cup made of the same material but enclosed in a solid container. Solo cups are only used once and then disposed of, filling our landfills unnecessarily. But imagine that the same Solo cup material is put made into a permanent coffee cup that could last ten years without being replaced. Sing Honeycomb protects the foam by sandwiching it inside a durable wood framework. LCA studies show that using wood is less harmful to the environment than steel or concrete in terms of embodied energy, global warming potential, air emissions, water emissions, and solid waste production.

3 Long Lasting Sing torsion-box sandwich panels are warranted for ten years*, but may last much longer. This means Sing products will not need replacement or disposal for many years, cutting down on the resources used to manufacture panels. The foam used in Sing Honeycomb Core Panels comes with a 20-year thermal performance warranty, dimensional stability, compressive strength, and water resistant properties. See instructions for repair and recycling.

4 Energy Friendly Energy Saving in general: Our Sing Honeycomb Core starts from raw material, production process, shipping and product lifespan, and the recycle/reuse are the major energy savings characteristics. Sing products has set a new bench-mark for energy savings and is less harmful to the environment than other honeycomb products. Sing core is the most energy friendly, covers more broad-range products in modern time today, all guaranteed by the inventor and founder of Sing Core. Energy Saving as insulation Insulated, draft-free sandwich panels save your heating costs Sing has a long term stable R-Value. Sing Sandwich panels assemble and install quickly, saving you man power and time.

5 Leading edge of composite technology Composite material is a feature of energy solutions to solve our structure needs. Patented Sing Core is the leader of composite material products. Sing Core takes less energy to produce the strongest, lightweight material. Whether the product is called a torsion box in the wood-working industry, a honeycomb panels in the aviation industry or a sandwich panel in the building industry, it’s all the same thing and they all function in the same way – it’s a composite material sandwiched with a lightweight core. There are many different core materials such as paper, aluminum even plastic honeycomb, but our Sing Honeycomb is a torsion box or sandwich core structured with a vertical grain core that takes less energy to produce from renewable resource to our finished honeycomb core that we’re proud to say is strongest, lightest weight core that is the most environmentally friendly composite product ever invented.

6 Recycled Our foam core has a recycled content of 20% and is 100% recyclable.

This is a Sing Overhead Garage Door Panel compared next to a typical steel overhead garage door panel. Same size and thickness but as you can see the steel panel buckles with only a few pounds put on it while the Sing Panel holds almost all of Inventor Peter Sings weight without any problem. *See Warranty

1-5 Sing Core Services

What Services Does Singcore Provide?

1 Standard Stock Items (sold by per sq ft or linear homes as Sing Eco Log and Sing logs) Please visit patented Sing product store, stock items are cut to size as Sing Sandwich panels and Sing Panels for you to create endless Sing products, such as all types of building materials, furniture ready for assembly (dresser, table, armoire, etc…) and including trade show panels, tiny houses and Sing log homes.

2. Special Order No matter how big the door or table, wall panel, large floor or wide plank floor and your true flatness requirement (for special order you may require the guarantee the flatness for your product at higher cost if it is extremely high end application). We could build a door to consider certain weight, strength, especially the flatness such as 16 ft tall door x 16 ft wide by even one inch thick or six inch thick within the target of your requirement (you will find out we might be the only company in the world that can offer you this special order service for any panel and post and beam made of Sing Core) for a broad spectrum of products for all types of industries.

3. Prototype Let us be part of your R and D team to use Sing technology to build an affordable lightweight, high strength and Eco-friendly products (there are hundreds of products applications could use Sing Core as a better alternative). All you need is to fill out our simple price quote form, describe the length, width, thickness and skin choice. We are offering a prototype discount for your new and innovative potential application. The money that you invest in your prototype will be fully refunded if you going to production mode and in exchange your success story and… Your creativity will make a better world. (*Please note It might be an adding fee for complicated or test cost for your further R and D Sing products . in addition of material cost.)

4. You Design, We Produce (OEM) Let Sing Core manufacture your products for your company, such as door and table substrate, lightweight wood, lightweight MDF or plywood. In all types of applications, Sing Core Products can replace lower quality, shorter lasting items at lower cost if order by truck load. You can be a leader in your industry (see part of our clients list that made the switch to patented Sing Core as an alternative to regular aluminum, steel, plywood, solid wood MDF) and as a top player in your industry we can Sing for you.

See Also: Sing to the World opportunities for global investors and non-profits

We offer: 1. Marketing of Sing Products 2. Production of Sing Products 3. Partner to Win the Bid

Sing Core is committed to our strict US made pledge.

Sing Core is committed to our strict US made pledge. “We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.

“We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.