Sing Core Partners with Architects and Designers for a Better World

Lightweight does not mean weak, heavy does not mean strong; just as low cost does not mean inferior. If you are searching for lightweight panel, post and beam in wood, metal, cement board, FPR or plastic for your building design project. Newly Patented Sing core is changing the public’s previous knowledge about lightweight honeycomb sandwich material. Sing core is the only material used in such a wide range of industries and it has endless applications.

Lightweight does not mean weak, heavy does not mean strong; just as low cost does not mean inferior. If you are searching for lightweight panel, post and beam in wood, metal, cement board, FPR or plastic for your building design project. Newly Patented Sing core is changing the public’s previous knowledge about lightweight honeycomb sandwich material. Sing core is the only material used in such a wide range of industries and it has endless applications.

Sing Core’s mission is to provide superior eco-friendly product to architects who have share a common goal with Sing product to build a better World creating a healthier, green planet, benefiting all creatures and life forms for extended sustainability for the future.

Sing Core is Eco-Friendly

Sing Core is manufactured with less, energy consumed, using earth-friendly renewable veneers. No formaldehyde is used in the adhesives between the structural and sandwich facings to ensure a true green end-product.

Sing Core is Lightweight

Sing Core is extremely lightweight. Though traditional honeycomb panels and products have been effectively used in your designs, patented Sing Core weight is approximately 4-6 lbs per cubic foot. No other core or sandwich material can lay claim to the lightweight advantages of patented Sing Core.

Sing Core is extremely lightweight. Though traditional honeycomb panels and products have been effectively used in your designs, patented Sing Core weight is approximately 4-6 lbs per cubic foot. No other core or sandwich material can lay claim to the lightweight advantages of patented Sing Core.

Sing Core is Strong

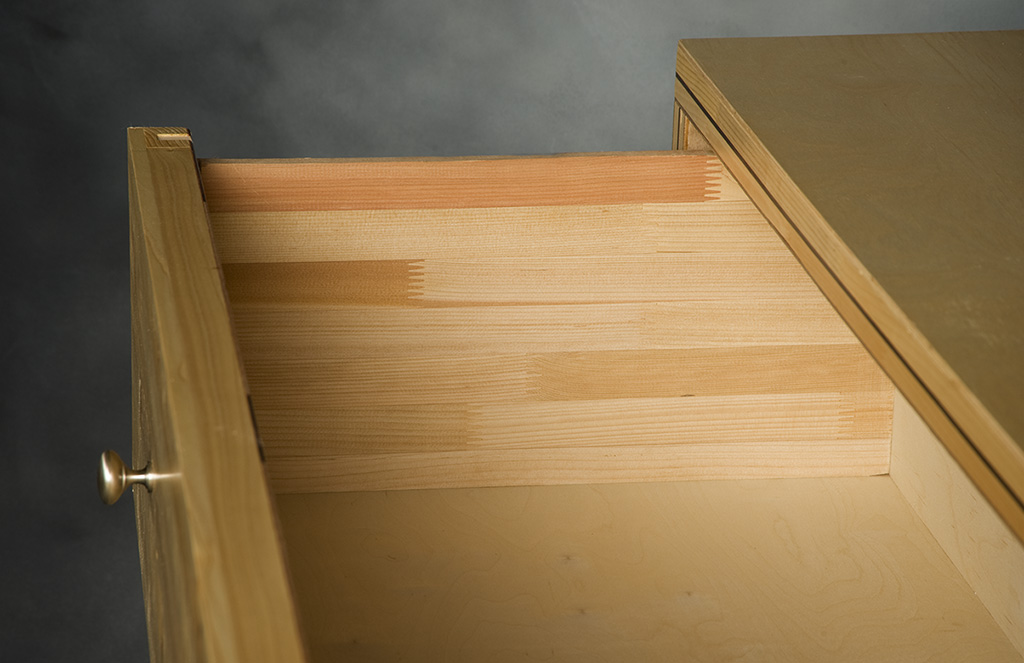

Traditional aluminum, paper and/or plastic honeycomb core cell size is commonly 3/8 inch to ¾ inch. The average compression strength are 10 to 100 psi; but the smallest Sing Core grid is 2 inch x 2 inch which when tested at the University of Washington reached 660 psi. for Sing Core’s honeycomb core.

The height of Sing Core could be 6 inches or more and still has superior strength but the average height of traditional cores are limited to mostly within one inch because the taller the core, the less compression strength. That is why you never see aluminum core in a 6 inch thickness, because they fail structurally. Sing Core maintains its strength and integrity in thickness of 6 inches or more. Sing Core is redefining, “lightweight and strong.”

Sing Core’s Unlimited Applications

Sing Core panels are available in thicknesses as little as 1/8”and as thick as 8 inches in lengths of 50 feet or longer, in aluminum, plywood, even cement bprad or ceramic tile or fiberglass or any other facing. Sing Core beams have superior structural integrity and can be 20 x 12 inches thick and 50 feet long (or more).

Sing Core is Made in the USA

Sing Core is Made in the USA

100% of Sing Core is proudly manufactured in the USA, using local labor supporting our community. Though Sing Core is also proud to be exported to other countries with green building agendas, our hope is to provide American jobs, supporting the American economy while making America greener and more sustainable, ensuring a bright future for generations to follow.

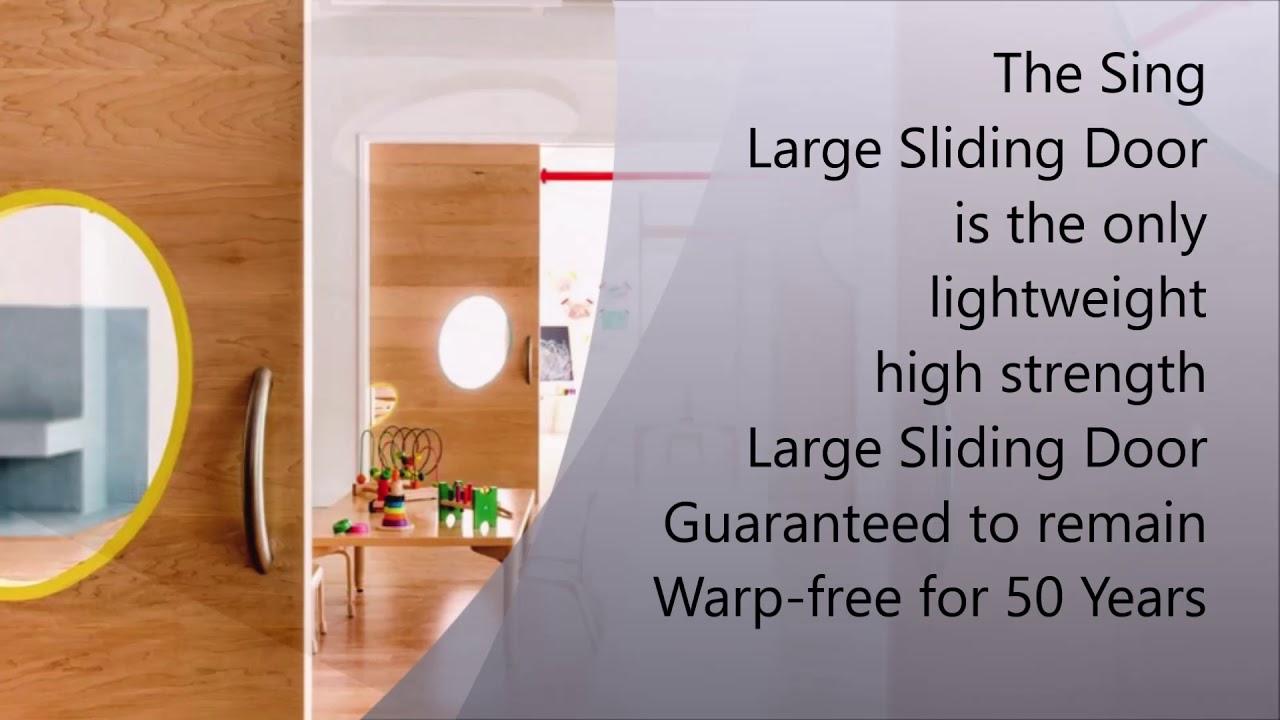

10 Year Warranty

Sing Core exceeds current code requirements. For example, in the door industry, AWI’s guidelines dictate that a door should be less than ¼ inch flatness. Sing Core routinely builds doors that are over 10 ft or longer in length, yet staying within those 7 ft doors code requirements. Doors made of Sing Core provide 10 years of structure warranty. As a common practice in door industry, most manufacturers offer only a one year warranty.

Products made with patented Sing Core can be easily repaired without compromising it’s original strength, due to the structure of Sing Core and the bonded stress skin which when compared to solid wood and other types of solid materials would pose a significant challenge.