Applications -> Building Components -> Doors -> Carriage Doors

How to Design Order and Build your Carriage Door

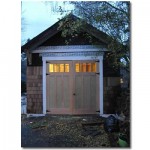

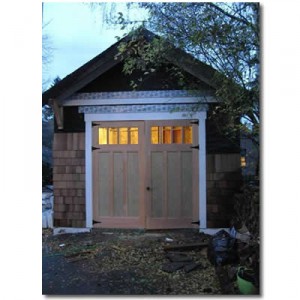

Sing Core is the top choice of discriminating home owners and high-end users making the switch from overhead doors to carriage doors who demand elegance and superior performance.

Sing Core is the top choice of discriminating home owners and high-end users making the switch from overhead doors to carriage doors who demand elegance and superior performance.

Sing Core Carriage Doors are imbued with unique characteristics that separate them from any other commercially available standard carriage door in the world. For instance,

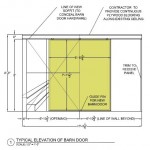

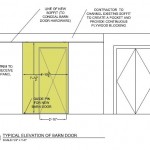

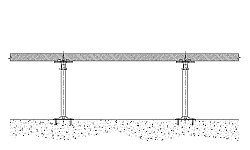

Sing Core Carriage Doors are available in outswing (standard), inswing, overhead, barn door and sliding door configurations to meet your individual requirements and specifications.

Sing Core offers a variety of surface materials to suit your individual tastes or to match the appearance of your classic design.

Due to their superior strength and load capacity in comparison to carriage doors made of other materials, Sing Core Carriage Doors are keenly suited for extreme weather conditions including temperature and humidity variations, storm and hurricane resistance*.

Regardless of your choice of exterior material (i.e. wood or steel), windows can be designed, cut and installed to match the overall appearance representation that you desire in your new garage door.

Sing Core Carriage Doors are the perfect adornment for your garage, studio or barn, giving you an unsurpassed aesthetic appeal while being functional and extremely structurally superior.

Sing Core Carriage Doors are the perfect adornment for your garage, studio or barn, giving you an unsurpassed aesthetic appeal while being functional and extremely structurally superior.

Each Sing Core Carriage Door is a precision garage door that is handcrafted in the USA and custom built to your specifications.

While capturing the beauty of century old carriage doors, Sing Core Carriage Doors are a fusion of old world technology and space-age technology to create a carriage door that is brilliantly adaptable, functional and will last for centuries.

Save Money

Sing Core Carriage Doors are the economically sound buyer’s choice for so many reasons, but have many ways to save you money. For instance,

Transportation and installation of your carriage doors is easier and less expensive due to weighing so much less than others.

Being lightweight also means less strain on the hardware and structure with normal use.

Being lightweight also means less strain on the hardware and structure with normal use.

Our pre-insulated carriage doors save you heating and cooling costs of your interior space.

The high-strength, true flat and long-life attributes, means less maintenance costs over time.

Sing Core Carriage Doors are competitively priced in comparison to other carriage doors. Why not take advantage of owning a superior end product, with all the added value of Sing Core without having to compromise your expectations, and are available in large, oversized doors.

Sing carriage doors vs. other overhead garage doors

Many people are making the change from overhead garage doors. Ask your overhead garage door company about Sing Carriage Doors.

Take advantage of this new technology increasing sales and profit by increasing value-added benefits and features, while decreasing costs and overhead.

Functional Sing Core enables the door manufacturer to build a similar or better than a high-end entrance door. Sing carriage doors are fully insulated, sound deadening, true flat, air tight, lightweight and super strong (backed by a 10 year structural guarantee).

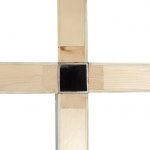

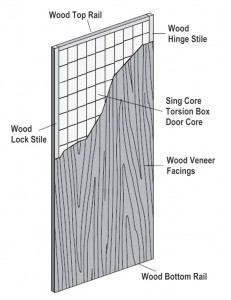

Functional Sing Core enables the door manufacturer to build a similar or better than a high-end entrance door. Sing carriage doors are fully insulated, sound deadening, true flat, air tight, lightweight and super strong (backed by a 10 year structural guarantee).- Replace Overhead Doors Many people are switching over from overhead doors to more elegant carriage doors, especially when converting a garage to a work shop, office space or even an extra guest room. Sing carriage doors can be air tight, effectively securing your space for heating in the winter and air conditioning in the summer. Sing Core is made of 90% foam and structure torsion box grids. Sing doors do not expand or move like solid wood carriage doors. This prevents the door from expanding due to the moisture and temperature change which can lead to air leakage or becoming too tight to close the door securely.

- Visually Impressive Compared to other garage doors and other carriage doors, sing carriage doors are true flat which will be easy to add design molding, various surface skins and/or textures, design and color detail by adding wood trim or molding. The resulting door is beautiful, enhancing the structure with unparalleled exquisite detail that remains close and tight over time without sagging even after years of use.

- Low Cost Carriage doors are the choice of high-end users and come with an equally high price tag. In comparison to overhead garage doors, customers will often choose the Sing carriage door because they cost less, yet are high-end, more attractive and function better than other garage doors. Once you consider the added cost of metal overhead doors, hardware and opener, Sing carriage doors are much less expensive. Our garage door companies reduce their costs while delivering more for their clients without sacrificing profit margin.

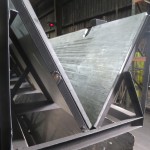

Easy to Build and Install Sing Core carriage door is lightweight, strong, true flat and works with regular hinges making it easy to move and install. When we first introduced Sing carriage doors, we attracted many DIY end-users who embrace the do-it-yourself philosophy that is becoming more of a trend. Highly successful results were enjoyed by these non-wood working trade professionals. If they can do it, so can you.

Easy to Build and Install Sing Core carriage door is lightweight, strong, true flat and works with regular hinges making it easy to move and install. When we first introduced Sing carriage doors, we attracted many DIY end-users who embrace the do-it-yourself philosophy that is becoming more of a trend. Highly successful results were enjoyed by these non-wood working trade professionals. If they can do it, so can you.- Easy to Market Obviously the high-end design and appearance of Sing Carriage doors are the key to engaging homeowners, clients and customers visually. But when you throw in all the added benefits, like, increased functionality, higher quality, sleek and styled appearance, increased lifespan, then you surprise them with a price-tag that is a fraction of a metal overhead or other type of garage door… it’s an easy decision.

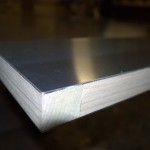

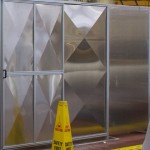

- Wide Variety of Surface Material Options Sing carriage doors have the largest selection of surface materials to accommodate any look, feel or design of any project. For instance, more popular door skins for Sing carriage doors include: wood, plywood, moisture resistant MDF, aluminum, stainless steel, FRP (fiber reinforced plastic), etc…

- Less Maintenance Compared to regular wood doors, Sing Core doors stay true flat, which prevents the moisture from soaking into the skin, like other solid wood and plywood that are likely to generate surface cracks, causing water to get into the inner layer of wood fiber, even when using proper sealants. Sing Core doors do not crack ensuring longer life for sealant/coating compared to any wood door, so you don’t have to worry about how to fix garage door. See characteristics, including rot resistance.

- Quality Assurance Sing Core is commonly used for extremely high-end, demanding jobs; this is why we offer the best structure warranty in the industry. We are making the largest doors in the door industry and boldly back them up with a 10-year warranty.

- Custom Size Sing carriage doors are available in any size. Custom sizing (even large, oversize) in any thickness, most any skin option, specialized insulated foam to accommodate your specifications, along with a variety of design molding. With Sing carriage doors, the sky’s the limit.

How to Build a True Flat Long Lasting Carriage Door

Wood-based carriage doors are exposed to a variety of weather conditions, glaring sun, wind and rain and it is important to keep the surface primed and coated to make sure that it does not crack while exposed to weather. Sing carriage doors prolong functionality of surface treatments due to being made with patented Sing Core’s torsion box structure that holds the wood surface to maintain a forever flat surface without twisting or cracking.

Wood-based carriage doors are exposed to a variety of weather conditions, glaring sun, wind and rain and it is important to keep the surface primed and coated to make sure that it does not crack while exposed to weather. Sing carriage doors prolong functionality of surface treatments due to being made with patented Sing Core’s torsion box structure that holds the wood surface to maintain a forever flat surface without twisting or cracking.

You may further weather-protect – even for withstanding the most severe weather conditions – by integrating other material into the surface of your Sing carriage door. Surface skins of aluminum, FRP or stainless steel will not crack like natural wood or plywood to prevent compromise of your Sing carriage door.

If you like the look of solid wood but seek high-performance and longevity, you can use Sing aluminum as your true flat carriage door’s substrate, you will be able to maintain straightness of your doors making them less likely to crack due to movement cause by expansion and contraction of the wood surface material.

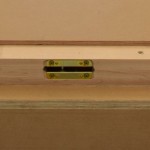

See how Sing Panel’s torsion box structure prevents surface crack because of the patented Sing Core’s unique characteristics. To keep your carriage door true flat is a challenge for solid wood or even plywood. Sing Core and Sing Panel master true flat technology for very high-end doors requiring less that 1/16 inch deflection which is more costly.

Sing carriage doors far exceed the AWI industry standard or ¼ inch deflection to be considered flat.

Imagine: No more overhead garage door repair needed.

Though Sing Core Carriage Doors can be customized to any specification,

an example of our standard Carriage Door would be:

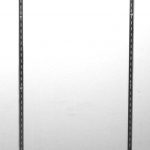

• 2 inches thick w/composite sandwich composition

• Can feature any standard exterior overlay

o Wood veneer (variety to specs)

o Solid Wood stave (any available wood species)

o Plywood

o Moisture resistant MDF

o Fiberglass / FRP

o Aluminum

o Stainless Steel

• Built-in insulation

• Paint grade

• Standard height/widths (8 ft. or less)

- Large insulated Sing honeycomb door

- Lightweight Sing honeycomb carriage door

- Patented honeycomb sandwich door

- Durable honeycomb carriage doors

- Insulated super strong honeycomb carriage door

- Large lightweight insulated swinging doors

- Large bi-fold sliding doors

- Over-sized Sing honeycomb bi fold door

- Insulated honeycomb durably door

- Insulated Sing sandwich carriage door

- Patented super strong garage door

Sing Core carriage doors are distributed by the most prestigious garage door companies.

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.