When you want to make a Large Exterior Door a Pivoting Door, turn to Sing Core, and we can make that happen.

|

|

Photo credit to Brandner for their beautiful finishing and installation

Large exterior doors are more prone to warp than interior doors because one side faces a temperature controlled environment, while the other side can be 100% exposed to the weather. With just a normal large exterior door you can look forward to a warping door. These large residential doors can include large feature doors, modern front doors, large pivot doors, and steel front doors, which are among the top few large door requests. Among other styles of big doors are patio doors, also often big doors which, like large front doors, are subject to warp due to changes according to surrounding elements.

|

|

|

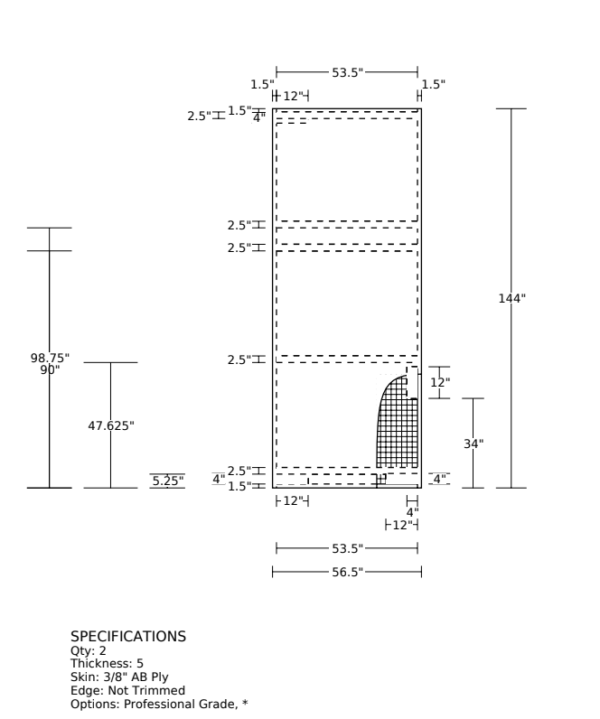

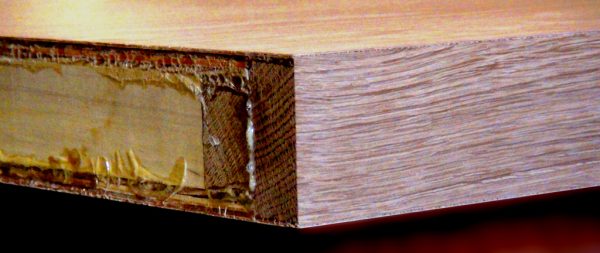

When you are planning to put a large pivoting door it is important to keep in mind some key points in order to have a great door. It’s well known that pivot doors fail more often than hinged doors because there’s only two points of contact on a pivot door. On a hinged door there are three or more anchor points on one side of the door to help keep the door straight. If a pivot door warps, bends, twists, or cups, the operation of the door can be severely compromised or fail altogether. At Sing Core we have the solution to the major issues with pivot doors. This is why having Sing Core inside your door, as it is the only way to build a lightweight sliding door. Sing Core Pivot Doors, like all Sing Core products, come with a 50 year structural and warp-free guarantee. You won’t find this common in the industry, as few products can hold up to it. Your door will last for 50 years without structural or warping issues, guaranteed.

At Sing Core these large pivoting doors are available in any size and are completely customizable. We offer different skin types or in other words we have wood doors, metal doors, fiberglass doors and more. And these doors can have light openings to allow view through the door. As previously stated our pivot doors are lightweight, extremely durable and stronger than steel. With traditional building methods, this could be unreasonable or even impossible. The weight of large doors alone leads to pricey installation and hardware, and they can still break, warp, and be otherwise ruined due to their size. At Sing Core our doors avoid all of these problems. The lightweight nature means that even the largest doors are still easy to operate and install, plus they don’t have nearly as much wear on the hardware as other door options. In addition, our doors are strong enough to protect whatever is behind your massive door. Each and every quality of a Sing Core door is present, regardless of size. The assembly is also quite simple thanks to our modular system, meaning you can connect the panels to form a door of virtually any size with ease.

Your home is the place you want to feel safe and confident. When you welcome guests the first thing they see is your door. Here at Sing Core we pride ourselves in making sure your door is perfect for all occasions. We work with a variety of architects and companies to make your door is exactly what you desire. When you have a company of choice all you say is that you want “Sing Core inside” and we will work together to create a beautiful door.