Introducing the new staple of lumber and hardwood mills, factories and yards:

Sing 2 x 12 Wood Plank

The Sing 2 x 12 is the most versatile eco-friendly hardwood lumber replacement in the world. Now available in Bamboo-style format.

The Sing 2 x 12 is the most versatile eco-friendly hardwood lumber replacement in the world. Now available in Bamboo-style format.

No other wood 2 x 12 can match the performance features of Sing’s 2×12, like:

- Lightweight

- Straight and true

- Twist, cup and warp resistant

- Super strong (stronger than steel lb for lb)

- Eco-friendly

Sing 2x12s are Flat, Straight and True

Each Sing 2×12 is extremely flat, with no twisting or cracking, unlike solid wood. Sing 2x12s can be used just like any other conventional hardwood, or softwood to build furniture, used as building material for boats, signs, planks, trade show displays, etc…

Sing 2x12s require no tongue-and-groove. Why? Because Sing 2x12s are straight and true, will not warp or twist over time. Therefore, assembling multiple lengths of Sing 2x12s is easy, painless and requires no tongue-and-groove to act as anti-warp control. Sing 2x12s can be joined edge-to-edge with standard carpenter glue, leaving a perfect seam every time, that will last the test of time.

Click here to see our Sing 2x12s in action in our 2×12 Photo Gallery.

Sing 2x12s are Dimensionally Stable

Lumber is unstable. You know what it’s like to try to find a straight piece of lumber… Then, once you use that piece of standard lumber, who’s to say how straight it will be in a year, or ten years? Tounge-and-groove was invented in an attempt to try to deal with the instability of commercially available lumber.

The unparalleled versatility makes Sing Core’s 2×12 the most amazing product to hit the woodworking industry since… the saw.

Sing 2 x 12 plank by itself will be idea to use as

Sing 2 x 12 plank by itself will be idea to use as

- substrate

- use as shelf

- stair treads

Sing plank can by saw to narrow plank to use as

- crown molding

- base molding

- trims

It has solid wood edge for edge glue to form any width and length to build

- large table top

- bench

- furniture part

- lightweight RV panel(s)

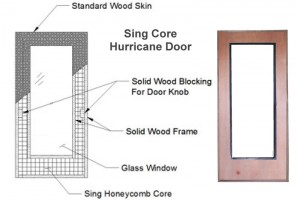

- plank door (or add veneer to build high-end wood grain door)

- raised floor

- wide plank floor

- wall

- roofing system

Take Your 2×12 to the Next Level

By adding aluminum on all sides than you have the perfect

- outdoor furniture

- trestle

- outdoor decking

- railing

Besides aluminum, the versatile 2x12s could be bonded to plastic, FRP, cement board, hardwood, metal… all can be options to use as external skins to create a stronger, lightweight, or all-weather material for different applications, including ceiling clouds.

Sing 2×12 Lumber, Metal and much more….

Sing 2×12 Lumber, Metal and much more….

The Sing 2×12 is not any type of soft wood or hardwood that you’ve ever known before; it is a basic material to build almost everything we use in our daily life.

1 Sing 2 x 12 x 8 foot panel

Why have we developed the Sing 2 x 12 x 8 foot Sing Plank?

- The Sing 2×12 is a superior match having the greatest amount of flexibility in diverse applications.

- Sing 2x12s can be produced in train load quantities. It has all the features of Sing Panels but at a lower cost. Sing 2 x 12 planks could use as substrate. Sing 2x12s can be edge-glued or end-glued to join and create any length or width. It is easy to append with any skin to accommodate any thickness. It is the most lightweight (1.5 lbs. per linear ft.), true flat and strongest insulated lumber ever invented.

Click here to see our Sing 2x12s in action in our 2×12 Photo Gallery.

2 Bamboo-style Sing 2×12 plank.

Why have we developed the Bamboo-style Sing 2 x 12 x 12 inch?

The only drawback when cutting 2 x 12 Sing Planks is exposing a portion of the Sing Core. When cutting the Sing 2×12 you need to remove a portion of the Sing Core and add insert a solid edge to end cap the exposed end. We have developed the solution by adding solid wood implants to create a Sing 2 x 12 like bamboo, providing cut points which will not expose Sing Core. It will have solid wood pre-installed at end of the Sing Panel cut point.

Due to the feedback of woodworkers who have heavy production schedules, we developed a new and improved Sing 2×12, that we call the Bamboo 2×12.

In much the same way that bamboo’s strength-cut-points occur naturally, Sing has scientifically redesigned the Sing 2×12 into its most prominent advancement, The Bamboo-style 2×12.

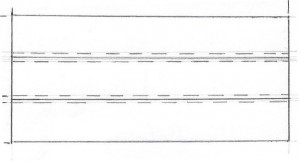

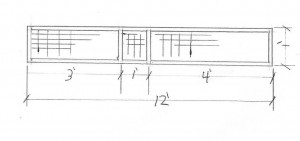

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

Cutting areas are precisely marked for your convenience. This allows for easy cross-cutting into lengths that are predetermined by the woodworking artist.

For instance, when cutting lengths of 1’, 3’, 4, 5’ or 8’ the nodes (or wood stiles) are pre-installed for convenient cross-cutting into these standard lengths.

Using the standard Sing 2×12, cutting an 8 foot length into two 4 foot lengths, would require the production team or woodworker to install wood styles at the cross-cut point, which may slow-down the production time.

Now, with the new and improved Bamboo-style 2×12, these challenges have been resolved, streamlining the production process

In the example (above) you can see how easy it is to edge-glue (using standard carpenter’s glue) Sing Bamboo 2x12s together into a large panel that could be used as a tabletop, counter, door, etc…

Question: If I need to build a door or table at 36 inch wide x 84 inch x 1.75 inch, what should I use Sing 2×12 plank or Sing Bamboo-style plank?

Answer: The Sing 2×12 Plank, because the Sing Bamboo-style 2×12 added cut-points would be superfluous (plus, the Sing 2×12 is less expensive).

Aesthetically, the Bamboo-style 2×12 and the Sing 2×12 look the same. If you require the Bamboo-style 2×12, you must specify when ordering.

- lightweight non warping honeycomb door

- Storage Shelves

- Any skin: HPL any size furniture components

- Dressers