- Exposed insulated inner structure

- Sing plywood panels make garbage bins that do not rot or warp or fall apart!

Sing 2×12 Lumber, Metal and much more….

Sing 2×12 Lumber, Metal and much more….

The Sing 2×12 is not any type of soft wood or hardwood that you’ve ever known before; it is a basic material to build almost everything we use in our daily life.

1 Sing 2 x 12 x 1.5 inch panel

Why have we developed the Sing 2 x 12 x 1.5 inch thick Sing Plank?

Click here to see our Sing 2x12s in action in our 2×12 Photo Gallery.

2 Bamboo-style Sing 2×12 plank.

Why have we developed the Bamboo-style Sing 2 x 12 x 12 inch?

The only drawback when cutting 2 x 12 Sing Planks is exposing a portion of the Sing Core. When cutting the Sing 2×12 you need to remove a portion of the Sing Core and add insert a solid edge to end cap the exposed end. We have developed the solution by adding solid wood implants to create a Sing 2 x 12 like bamboo, providing cut points which will not expose Sing Core. It will have solid wood pre-installed at end of the Sing Panel cut point.

Due to the feedback of woodworkers who have heavy production schedules, we developed a new and improved Sing 2×12, that we call the Bamboo 2×12.

In much the same way that bamboo’s strength-cut-points occur naturally, Sing has scientifically redesigned the Sing 2×12 into its most prominent advancement, The Bamboo-style 2×12.

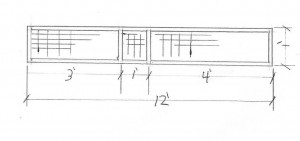

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

Cutting areas are precisely marked for your convenience. This allows for easy cross-cutting into lengths that are predetermined by the woodworking artist.

For instance, when cutting lengths of 1’, 3’, 4, 5’ or 8’ the nodes (or wood stiles) are pre-installed for convenient cross-cutting into these standard lengths.

Using the standard Sing 2×12, cutting an 8 foot length into two 4 foot lengths, would require the production team or woodworker to install wood styles at the cross-cut point, which may slow-down the production time.

Now, with the new and improved Bamboo-style 2×12, these challenges have been resolved, streamlining the production process

In the example (above) you can see how easy it is to edge-glue (using standard carpenter’s glue) Sing Bamboo 2x12s together into a large panel that could be used as a tabletop, counter, door, etc…

Question: If I need to build a door or table at 36 inch wide x 84 inch x 1.75 inch, what should I use Sing 2×12 plank or Sing Bamboo-style plank?

Answer: The Sing 2×12 Plank, because the Sing Bamboo-style 2×12 added cut-points would be superfluous (plus, the Sing 2×12 is less expensive).

Aesthetically, the Bamboo-style 2×12 and the Sing 2×12 look the same. If you require the Bamboo-style 2×12, you must specify when ordering.

How to build your own large, oversize panels using Sing Sandwich Panels of other Sing Substrate as your Sing Core using a variety of methods to join them together.