Carriage Doors

Applications -> Building Components -> Doors -> Carriage Doors

How to Design Order and Build your Carriage Door

Sing Core is the top choice of discriminating home owners and high-end users making the switch from overhead doors to carriage doors who demand elegance and superior performance.

Sing Core is the top choice of discriminating home owners and high-end users making the switch from overhead doors to carriage doors who demand elegance and superior performance.

Sing Core Carriage Doors are imbued with unique characteristics that separate them from any other commercially available standard carriage door in the world. For instance,

Sing Core Carriage Doors are available in outswing (standard), inswing, overhead, barn door and sliding door configurations to meet your individual requirements and specifications.

Sing Core offers a variety of surface materials to suit your individual tastes or to match the appearance of your classic design.

Due to their superior strength and load capacity in comparison to carriage doors made of other materials, Sing Core Carriage Doors are keenly suited for extreme weather conditions including temperature and humidity variations, storm and hurricane resistance*.

Regardless of your choice of exterior material (i.e. wood or steel), windows can be designed, cut and installed to match the overall appearance representation that you desire in your new garage door.

Sing Core Carriage Doors are the perfect adornment for your garage, studio or barn, giving you an unsurpassed aesthetic appeal while being functional and extremely structurally superior.

Sing Core Carriage Doors are the perfect adornment for your garage, studio or barn, giving you an unsurpassed aesthetic appeal while being functional and extremely structurally superior.

Each Sing Core Carriage Door is a precision garage door that is handcrafted in the USA and custom built to your specifications.

While capturing the beauty of century old carriage doors, Sing Core Carriage Doors are a fusion of old world technology and space-age technology to create a carriage door that is brilliantly adaptable, functional and will last for centuries.

Save Money

Sing Core Carriage Doors are the economically sound buyer’s choice for so many reasons, but have many ways to save you money. For instance,

Transportation and installation of your carriage doors is easier and less expensive due to weighing so much less than others.

Being lightweight also means less strain on the hardware and structure with normal use.

Being lightweight also means less strain on the hardware and structure with normal use.

Our pre-insulated carriage doors save you heating and cooling costs of your interior space.

The high-strength, true flat and long-life attributes, means less maintenance costs over time.

Sing Core Carriage Doors are competitively priced in comparison to other carriage doors. Why not take advantage of owning a superior end product, with all the added value of Sing Core without having to compromise your expectations, and are available in large, oversized doors.

Sing carriage doors vs. other overhead garage doors

Many people are making the change from overhead garage doors. Ask your overhead garage door company about Sing Carriage Doors.

Take advantage of this new technology increasing sales and profit by increasing value-added benefits and features, while decreasing costs and overhead.

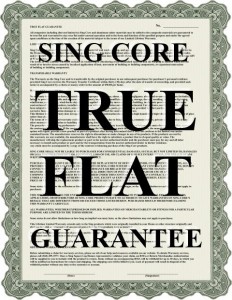

Functional Sing Core enables the door manufacturer to build a similar or better than a high-end entrance door. Sing carriage doors are fully insulated, sound deadening, true flat, air tight, lightweight and super strong (backed by a 10 year structural guarantee).

Functional Sing Core enables the door manufacturer to build a similar or better than a high-end entrance door. Sing carriage doors are fully insulated, sound deadening, true flat, air tight, lightweight and super strong (backed by a 10 year structural guarantee).- Replace Overhead Doors Many people are switching over from overhead doors to more elegant carriage doors, especially when converting a garage to a work shop, office space or even an extra guest room. Sing carriage doors can be air tight, effectively securing your space for heating in the winter and air conditioning in the summer. Sing Core is made of 90% foam and structure torsion box grids. Sing doors do not expand or move like solid wood carriage doors. This prevents the door from expanding due to the moisture and temperature change which can lead to air leakage or becoming too tight to close the door securely.

- Visually Impressive Compared to other garage doors and other carriage doors, sing carriage doors are true flat which will be easy to add design molding, various surface skins and/or textures, design and color detail by adding wood trim or molding. The resulting door is beautiful, enhancing the structure with unparalleled exquisite detail that remains close and tight over time without sagging even after years of use.

- Low Cost Carriage doors are the choice of high-end users and come with an equally high price tag. In comparison to overhead garage doors, customers will often choose the Sing carriage door because they cost less, yet are high-end, more attractive and function better than other garage doors. Once you consider the added cost of metal overhead doors, hardware and opener, Sing carriage doors are much less expensive. Our garage door companies reduce their costs while delivering more for their clients without sacrificing profit margin.

Easy to Build and Install Sing Core carriage door is lightweight, strong, true flat and works with regular hinges making it easy to move and install. When we first introduced Sing carriage doors, we attracted many DIY end-users who embrace the do-it-yourself philosophy that is becoming more of a trend. Highly successful results were enjoyed by these non-wood working trade professionals. If they can do it, so can you.

Easy to Build and Install Sing Core carriage door is lightweight, strong, true flat and works with regular hinges making it easy to move and install. When we first introduced Sing carriage doors, we attracted many DIY end-users who embrace the do-it-yourself philosophy that is becoming more of a trend. Highly successful results were enjoyed by these non-wood working trade professionals. If they can do it, so can you.- Easy to Market Obviously the high-end design and appearance of Sing Carriage doors are the key to engaging homeowners, clients and customers visually. But when you throw in all the added benefits, like, increased functionality, higher quality, sleek and styled appearance, increased lifespan, then you surprise them with a price-tag that is a fraction of a metal overhead or other type of garage door… it’s an easy decision.

- Wide Variety of Surface Material Options Sing carriage doors have the largest selection of surface materials to accommodate any look, feel or design of any project. For instance, more popular door skins for Sing carriage doors include: wood, plywood, moisture resistant MDF, aluminum, stainless steel, FRP (fiber reinforced plastic), etc…

- Less Maintenance Compared to regular wood doors, Sing Core doors stay true flat, which prevents the moisture from soaking into the skin, like other solid wood and plywood that are likely to generate surface cracks, causing water to get into the inner layer of wood fiber, even when using proper sealants. Sing Core doors do not crack ensuring longer life for sealant/coating compared to any wood door, so you don’t have to worry about how to fix garage door. See characteristics, including rot resistance.

- Quality Assurance Sing Core is commonly used for extremely high-end, demanding jobs; this is why we offer the best structure warranty in the industry. We are making the largest doors in the door industry and boldly back them up with a 10-year warranty.

- Custom Size Sing carriage doors are available in any size. Custom sizing (even large, oversize) in any thickness, most any skin option, specialized insulated foam to accommodate your specifications, along with a variety of design molding. With Sing carriage doors, the sky’s the limit.

How to Build a True Flat Long Lasting Carriage Door

Wood-based carriage doors are exposed to a variety of weather conditions, glaring sun, wind and rain and it is important to keep the surface primed and coated to make sure that it does not crack while exposed to weather. Sing carriage doors prolong functionality of surface treatments due to being made with patented Sing Core’s torsion box structure that holds the wood surface to maintain a forever flat surface without twisting or cracking.

Wood-based carriage doors are exposed to a variety of weather conditions, glaring sun, wind and rain and it is important to keep the surface primed and coated to make sure that it does not crack while exposed to weather. Sing carriage doors prolong functionality of surface treatments due to being made with patented Sing Core’s torsion box structure that holds the wood surface to maintain a forever flat surface without twisting or cracking.

You may further weather-protect – even for withstanding the most severe weather conditions – by integrating other material into the surface of your Sing carriage door. Surface skins of aluminum, FRP or stainless steel will not crack like natural wood or plywood to prevent compromise of your Sing carriage door.

If you like the look of solid wood but seek high-performance and longevity, you can use Sing aluminum as your true flat carriage door’s substrate, you will be able to maintain straightness of your doors making them less likely to crack due to movement cause by expansion and contraction of the wood surface material.

See how Sing Panel’s torsion box structure prevents surface crack because of the patented Sing Core’s unique characteristics. To keep your carriage door true flat is a challenge for solid wood or even plywood. Sing Core and Sing Panel master true flat technology for very high-end doors requiring less that 1/16 inch deflection which is more costly.

Sing carriage doors far exceed the AWI industry standard or ¼ inch deflection to be considered flat.

Imagine: No more overhead garage door repair needed.

Though Sing Core Carriage Doors can be customized to any specification,

an example of our standard Carriage Door would be:

• 2 inches thick w/composite sandwich composition

• Can feature any standard exterior overlay

o Wood veneer (variety to specs)

o Solid Wood stave (any available wood species)

o Plywood

o Moisture resistant MDF

o Fiberglass / FRP

o Aluminum

o Stainless Steel

• Built-in insulation

• Paint grade

• Standard height/widths (8 ft. or less)

- Large insulated Sing honeycomb door

- Lightweight Sing honeycomb carriage door

- Patented honeycomb sandwich door

- Durable honeycomb carriage doors

- Insulated super strong honeycomb carriage door

- Large lightweight insulated swinging doors

- Large bi-fold sliding doors

- Over-sized Sing honeycomb bi fold door

- Insulated honeycomb durably door

- Insulated Sing sandwich carriage door

- Patented super strong garage door

Sing Core carriage doors are distributed by the most prestigious garage door companies.

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.

How to Build a True Flat Wood Door

True flat technology is based on expertise in building any door that can be guaranteed true flat and stay flat. This composite science includes the proper proportions of Sing Core, aluminum and/or other materials and bonding agents based on your requirements or specifications. In this way each Sing door is a work of art.

One of the challenges in building any wood product of any dimension where the customer desires a perfectly flat surface over long spans is insurmountable in many circumstances.

This is the proven niche specialty service provided by Sing Core to the worlds most high-end, demanding, high-profile millworks and end users for years. Due to the unique properties of the patented Sing Core material, true flat designs can come to life and deliver superior satisfaction while carrying a 10 year structural guarantee.

AWI standards may allow for a certain amount of deflection over long spans, the patented Sing Core material far exceeds deflection allowances of other materials, due to its torsion box design while remaining true flat.

This is why the most prestigious millworks in the United States turn to Sing Core for their large, oversize doors, though they have the added benefits of having an end product that is:

Eco-friendly

Eco-friendly- Renewable

- Dimensionally stable

- Extremely Strong

- Light weight

- Insulated

- Sound deadening

- Easy to machine

And could be customized to include:

- Waterproof

- Fire retardant

- Bullet-proof

- Any Thickness

- Almost unlimited skin options

- Fast turnaround

The True Flat Challenge

The true flat door is a challenge for architects, door manufacturer, millworks and general contractors, especially if the door is 1 inch thick (or more), over 8 feet wide and/or 16+ feet tall.

If you’re looking for the answer, you might Google search how to build a true flat door.

Oversize doors present the biggest challenge for true flatness, but they also present other issues that must be dealt with in high end homes and/or commercial applications in terms of weight and strength. Again, let’s see what Google has to say about lightweight high strength true flat?

The clear answer is Sing Core; a new invention of material that is playing a major role – not just in building large doors – but almost anything that requires (or desires) to be Eco-friendly, functional yet elegant for inside/outside a home or in building and construction that needs to be light, strong and sustainable

Aluminum composites are common in the aerospace industry, but are cost prohibitive and not user-friendly for mill working or broad earth-bound use. Sing Core is designed to be used in millworks and does not require any specially-trained labor or specialized equipment; treat it just like you would any other standard wood-based substrate material.

Sing Core’s true flat process utilizes vertical grain torsion-box/foam-core/aluminum composites to deliver the solution. Contact us for more information, and if you like, we will show you how to integrate this new technology into your operation.

Meeting the Highest Demands

We maintain the highest degrees of integrity when meeting the requirements of our clients, and their customers, assuring complete satisfaction. Most importantly, proper communication is the key. If you have certain expectations – and you let us know – our team can deliver the product that matches your specifications.

We maintain the highest degrees of integrity when meeting the requirements of our clients, and their customers, assuring complete satisfaction. Most importantly, proper communication is the key. If you have certain expectations – and you let us know – our team can deliver the product that matches your specifications.

Simply by providing us with your dimensional requirements:

- height

- width

- thickness

along with what your preference for visual presentation (exterior skin material) and performance expectations are, we can provide you with the solution to best suit your application.

How Do We Do It?

When you explain to us what your expectations are, we know how to create the product that meets or exceeds your expectations. For instance, if you require a 17 foot tall oak pivot door that is true flat.

First of all, if the pivot door were solid oak, it would fail the standards test due to the raw material. Natural wood will warp, twist and crack if left to itself. Not to mention being heavy in weight. The excessive weight is an added strain on the integrity of the structure and hardware, increasing maintenance costs over time.

Our designers will likely prescribe a solution that begins with a Sing Core base material in the center which is by itself perfectly flat. Adding oak wood staves is where the problem comes in; because natural wood is unstable and will compromise the overall structure. To combat this issue, our team may fuse the Sing Core material to aluminum to complete the substrate composite. Then, when the exterior oak faces are applied to the structure; like magic, the result is a lightweight, super strong solution that can be perfectly flat.

Our designers will likely prescribe a solution that begins with a Sing Core base material in the center which is by itself perfectly flat. Adding oak wood staves is where the problem comes in; because natural wood is unstable and will compromise the overall structure. To combat this issue, our team may fuse the Sing Core material to aluminum to complete the substrate composite. Then, when the exterior oak faces are applied to the structure; like magic, the result is a lightweight, super strong solution that can be perfectly flat.

The resulting Sing Core lightweight solution does not compromise the structure or the hardware eliminating expensive repairs and/or maintenance.

That’s just one example. Some of the materials used in our true flat composite resolutions that battle the temperature and moisture weaknesses that accompany utilizing natural components (like wood) include

Our lifetime of experience dedicated to solving the challenges of architects, designers and craftsmen who serve the most prestigious clientele, especially in terms of sustainable, lightweight, super strong and true flat solutions that maintain structural integrity over many years, while retaining the beauty and elegance of natural wood (or any other desired external material).

Metal is used across many industries. Metal honeycomb composite is the leader in honeycomb cores used to create stronger and lighter metal panels as well as posts and beams using much less solid metal.

Sing core is the leading technology of metal honeycomb composite material that solves our future Eco-friendly energy solution by using Sing metal honeycomb composite at a fraction of the weight of solid steel, but is stronger, lightweight, and available in steel plate, steel beam and steel panels.

Tell the US Energy Department to do some home work and research the Sing solution. If you believe Sing Core will help us use less metal thanks to Sing honeycomb metal.

Case study #1: Do not waste more precious metal if you could use Sing Metal honeycomb panel, post and beam.

Replace steel by using Sing 13 ft x 3 ft x 1 inch Sing honeycomb metal plate for use in conveyor.

1 Advantage: Precision true flat – within thousands of an inch – the majority of metal fabrication relies heavily on welding that causes the metal to deform. Sing metal uses structural glue, nuts and bolts instead of welding metal plates onto the steel frame which takes more labor, energy and end the product will not match the same precision as Sing Metal honeycomb panels.

2 Easy to fabricate and install – lightweight metal is safer to process, costs less to transport and uses less labor to install.

3 Less cost: Solid metal takes many times more metal than Sing Metal panels, posts and beams. It is expensive to transport, takes more energy to process and the most important thing is that Sing Metal is much less expensive than solid metal planks or sheets. If the strength, lightweight and Eco-friendly attributes are considered you may never go back to solid metal again.

Case study #2: If your seeking to improve your products with greater precision, true flat doors or panels, walls, floors, ceilings, RVs and/or boats then we’d like to teach you to Sing.

This is the latest technology to build true flat doors. If we are able to build a true flat door then you can believe that we could make true flat floors, ceilings, walls, etc… all lightweight, high strength, long lasting and endless benefits just by Singing with us.

This is the latest technology to build true flat doors. If we are able to build a true flat door then you can believe that we could make true flat floors, ceilings, walls, etc… all lightweight, high strength, long lasting and endless benefits just by Singing with us.

Doors are a challenge for door manufacturers and mill works if the door is over 8 ft in length and less than in inch thick.

One of the Sing aluminum honeycomb panels are used as door substrate. It used in almost all major high end residential and commercial door applications due to the true flat characteristics. AWI standards for true flat include deflection of ¼ inch, which is unacceptable for Sing Core. We can minimize deflection to 1/8th or even 1/16th according to your pre-arranged specifications and application requirements to ensure satisfaction.

But if you have a door over 12 ft – even over 16 ft tall – and less than 1.5 inch in thickness and you are wishing to have the least deflection than you need to contact www.singcore.com to find the true flat solution which is use aluminum panel as substrate than add MDF or AB plywood for paint grade door or by cold or hot press to add finish veneer to build the most beautiful, strong, lightweight eco friendly door.

Doors made of Sing Aluminum honeycomb substrate do not need to acclimatize due to there being no moisture difference on either side of the door substrate.

Sing Aluminum honeycomb door substrate can be machined or drilled just like wood without retooling or damaging your blades. It is easy to glue with proper clean up procedure.

Large over size doors for high end building project require the true flatness. Patented Sing Core is the ultimate solution for high end mill work across the country.

Please click to see clients list of those who use Sing Core doors.

Applications -> Building Components -> Doors -> True Flat Wood Door

Ceramic

Sing Core is the revolutionary ceramic laminate substrate that supersedes all other ceramic reinforcement while being lightweight, stronger than steel and eco-friendly.

Working hand-in-hand with architects, designers, contractors and end-users, Sing Core ceramic substrate helps to solve the structural challenges often associated with ceramic-work including remaining true-flat, while maintaining the highest levels of structural integrity and minimizing construction and maintenance costs.

Working hand-in-hand with architects, designers, contractors and end-users, Sing Core ceramic substrate helps to solve the structural challenges often associated with ceramic-work including remaining true-flat, while maintaining the highest levels of structural integrity and minimizing construction and maintenance costs.

Applications include:

- Bathrooms

- Ceramic tile floors

- Commercial kitchens

- Countertops

- Doors

- Floors

- Laboratories

- Marine

- Pivot doors

- Refrigeration floors

- Saunas

- Stair treads

- Tables

- Wall art

- Walls

Our Sing composite ceramic skinned panels are ideal for use as fireproof doors. With the Sing Honeycomb as a substrate it will reduce the impact which is the major cause of cracking on ceramics. See our YouTube channel to see the unbreakable mirror video by Sing Honeycomb. This is the same principle that will keep ceramic panels strong.

Other Sing composite panel solutions can be found as other building materials.

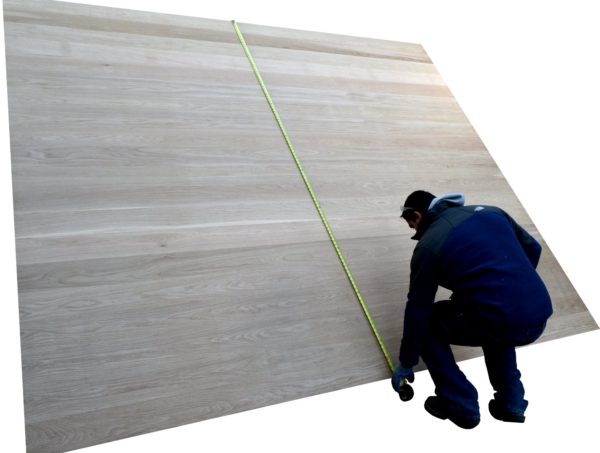

Lightweight Export Beams and Panels for Thailand Skyscraper

We specialize in Large Oversize Doors

We are exporting Sing Core to provide the tallest skyscrapers in Bangkok with the solutions to their design problems.

(Photo above, pre-export at home in the USA)

What design problems do you think they have? Mostly the same problem all large project designers run into, like the complexities of ecologically friendly, lightweight, strength and integrity over long lengths. Sing Core is the superior solution for these obstacles.

Photos here are of a container of Sing Core beams and panels used in the construction of one of the tallest buildings in Bangkok, Thailand. This is likely one of the only patented plywood product to be exported to Asian countries. Why? Much of our plywood is imported because they can manufacture it so inexpensively off-shore. In fact, their prices are so low that American companies have accused them of dumping product to bury the American wood industry, resulting in a 25% import duty on imported plywood products.

So, think about that… Asia importing Sing panels and beams… The only reason that they would do that is if it was the only way to solve their design problems; and nothing fits the bill like Sing Core.

From an export point of view, note that the shipment of product is ten times stronger than standard wood product, yet weigh 70 to 80 percent less than the equivalent plywood.

In a time when the United States is encouraging you to not to import by charging a 25% tariff on incoming plywood, why not shop at home and consider a structural technology that is far superior not only to import varieties, but nearly any other conventional construction material.

In case you are unaware of the Sing Core technology; here is a basic rundown:

The Sing Core is based on primitive torsion box honeycomb designs, but is exponentially improved upon the basic design.

Sing Core is manufactured with LESS

- raw materials

- labor

- equipment cost.

Our unique manufacturing process requires LESS

- energy for production

- space

- and makes less waste.

Sing Core panels are

- true flat

- fully insulated

- sound deadening

- lightweight

- extremely strong

- last the test of time

- and are earth friendly.

That is why the supplier of high-end custom-built oversize products to the

- President

- Prime Minister

- Kings

- and the Pope

has sought out Sing Core as their solution. Yet, we make this technology affordable, even to compete with cheap imports.

If you are currently importing substandard plywood from off-shore, shouldn’t you think about being proud to say, “Made in the USA,” reducing your costs, delivery times and providing your clients with a superior product that is not only eco-friendly but “true green”?

Spend Less Get More With Sing Core

Door Sliding

Applications -> Building Components -> Doors -> Door Links -> Sliding Pocket Doors

Sliding and Pocket Doors

Products > Door > Sliding Door

Sliding/Pocket Doors

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel. See our new C Series line of Affordable Barn Door and Sliding Closet Doors.

How to Buy

Sing Core door panels are easy to order. You may choose from our stock panels or order custom-sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day.

Custom doors without the custom pricing!

Sing Core door panels are available at a fraction of the price of conventional sliding door/pocket door panels. Sing Door Panels are insulated, lightweight, stronger and more dimensionally stable than solid wood panels – at less than half the price!

When using Sing Panels, you design your own door by adding the trim, paint, and hardware. Sing Core door panels are great for millwork shops and door manufacturers. Exclusive pricing is available to distributors and retailers.

Door Assembly Instructions:

You can combine these to make almost any size door you desire. Once your door panels have arrived, place them in the room where they will be installed and do the following:

1. Arrange your door panels on a level plane so that they can be joined precisely.

2. Join the panels in the horizontal position and applying glue in the grooved “biscuit” pocket.

3. Insert biscuit joint into one side of panel, apply glue to groove in second panel that will be attached to the first panel

4. Slide panel so that the other half of the biscuit is inserted into the biscuit groove and apply adequate pressure to the glued area. (We recommend formaldehyde-free, urethane glue)

5. Once all of the panels have been assembled together and the glue has completely dried, your Sing Core door is ready to install.

Check out the tutorial videos at the bottom of this page. Contact us if you have further questions/concerns on how to install our Sing Core door panels.

Order Custom Sizes:

To order custom door sizes, please submit a work order form. We’ll respond to you with a quote within two business days.

Installing a Sliding Factory Door

Step 1: Install the sliding door track.

Step 2: Prepare door for hardware installation.

Step 3: Install hardware and hang the door to make sure of fit and function.

Step 4: Finish and paint the doors.

Step 5: Admire your newly install Sing Sandwich Panel Sliding Doors.

Gallery | Technical Info | FAQ | Order Form | Standard Pricing

Case Studies

Title: Steam Room Door

Client: Pizza Company

Product: Sing Panels

Challenge:The client needed doors that resist moisture and close securely. He also needed the doors to withstand frequent use at a business.

Sing Solution:Sing Core doors are flat and straight enough to keep humidity from leaving the steam room. Water resistant coating was applied to protect the door, preventing it from warping and rotting.

Customer Quote:

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Title: Children’s Room

Client: Tremain Construction

Location: Washington State

Product: Sing Panels

Challenge: The family needed a large divider for their living room. It needed to be lightweight so that the kids could open and close it easily.

Sing Solution:Sing Core panels are light enough for a small child to move and easy to assemble. The family finished the doors with chalkboard paint to make it kid-friendly.

Customer Quote:

“As you can see, the photo below was taken right after install and finishing completed, still construction stuff in the area. The other picture is after the owners moved in and their kids started using the door, which is covered with blackboard paint; it becomes a moving mural in the space.” -P

- aluminum sing honeycomb lightweight non warping sliding door

- sing honeycomb lightweight aluminum sandwich

- glass sing honeycomb non warping sliding door

- honeycomb lightweight sandwich honeycomb door

- true flat sing honeycomb lightweight

- Sliding Barn Door Room Separation

- Bay of Large Storage Cabinets

- Contemporary sing honeycomb sandwich lightweight wood

- Sing honeycomb lightweight sandwich wood

- patented Sing honeycomb sandwich closet door

- Oversize Pocket Doors

- non warping strong honeycomb sandwich

- sing honeycomb lightweight glass sandwich

- oversize lightweight high strength honeycomb door

- large oversize lightweight high strength sing sandwich door

- lightweight high strength large honeycomb door