We are so excited to disclose the details of the secrets that we have discovered enabling some of our finest clients to achieve the highest performance in large wood stave products guaranteed not to warp, bend, twist or otherwise fail for 50 years.

We are so excited to disclose the details of the secrets that we have discovered enabling some of our finest clients to achieve the highest performance in large wood stave products guaranteed not to warp, bend, twist or otherwise fail for 50 years.

The reason the secret has never been revealed before is due to it never being possible to create a perfectly straight large wood stave product. Wood will move (warp) or fail due to its nature; that is, until we accomplished creating non-warping products for two of our most exclusive clients.

Wood Veneer

Prior to this, wood veneer was the only option for even hoping to have a mostly flat surface, but this is still an issue when attempting to cover a long span. For instance, in an oversize large wooden table or oversized wood door, if warping is a concern, wood veneer adequately deals with the tendency of thicker wood grain surface material to move and vary over time and distance.

Prior to this, wood veneer was the only option for even hoping to have a mostly flat surface, but this is still an issue when attempting to cover a long span. For instance, in an oversize large wooden table or oversized wood door, if warping is a concern, wood veneer adequately deals with the tendency of thicker wood grain surface material to move and vary over time and distance.

While wood veneer is handy, it will not survive damage very well and may not be repairable, like a solid wood stave.

We understand the advantages and nature of all types of veneers while working hand-in-hand with the veneer industry.

The Problem

Two separate clients from different locations of the United States sought us out to solve this problem:

Large doors that are often extremely heavy and often fail due to the excessive weight causing strain on the hardware and structure and warping compromising the door’s sealing capabilities.

Both clients expected a lightweight solution that was not only as warp-proof as possible but could maintain the highest degree of tolerance for flatness across the surface area. They were servicing high-end customers who understand the limitations of traditional building materials yet enthusiastically willing and able to finance the discovery of new methods to provide a no-fail solution.

Both clients expected a lightweight solution that was not only as warp-proof as possible but could maintain the highest degree of tolerance for flatness across the surface area. They were servicing high-end customers who understand the limitations of traditional building materials yet enthusiastically willing and able to finance the discovery of new methods to provide a no-fail solution.

The Solution Case Study

In these recent scenarios, one client requested solid mahogany wood stave while the other desired stainless steel 12 ft. x 10 ft. true flat doors. Both present their own share of challenges.

We were honored to take on the challenges – as we have always been when helping all our clients – and never more excited to know that we had overcome the challenges and achieved an entirely new level of high precision and high performance. So high, in fact, that even we had never attempted such a high standard challenge before.

The Results

The Results

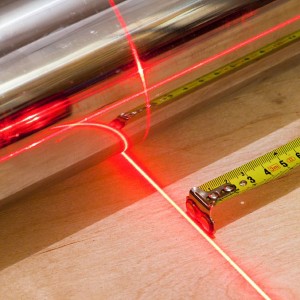

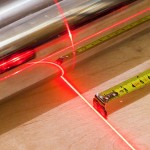

We were able to produce high performance lightweight doors that were stronger than steel pound for pound, had the highest tolerance (the core approximately within .006 inch) and guaranteed not to warp, bend, twist of otherwise fail for 50 years!

That creates a new standard for the most precision high performance large doors made of hardwood or any other flat building material.

The Secret Revealed

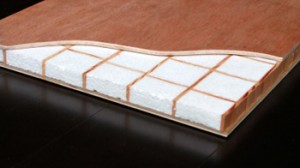

The only way we could have achieved such high precision and high performance is due to the secret ingredient in the door’s core material: Sing Core. With patented Sing Core in the heart of these doors we were able to achieve these unprecedented standard results.

The only way we could have achieved such high precision and high performance is due to the secret ingredient in the door’s core material: Sing Core. With patented Sing Core in the heart of these doors we were able to achieve these unprecedented standard results.

The secret of Sing Core lies in its unique reinforced vertical grain torsion box honeycomb core. There is no other Eco-friendly honeycomb panel material made in the USA that is lightweight, so strong (660 PSI) and can traverse long spans with little or no deflection. See comparison.

Secret Infused Applications

Now that we have achieved the results that were previously not possible by any known building technology, it is easy to see that a door could also be a wall. Laid flat; could be a floor, ceiling, roof, table or countertop.

Now that we have achieved the results that were previously not possible by any known building technology, it is easy to see that a door could also be a wall. Laid flat; could be a floor, ceiling, roof, table or countertop.

How could you apply this technology to other applications?

Sustainable Longevity

Using patented Sing Core in practically anything can add life to products and projects that previously had a relatively short life expectancy were disposable and created a high demand on waste resources.

Consider using Sing Core in your next project for a better world.