The Making of a Sing Core Door

When you first consider ordering a Sing Core door panel, you may wonder what all goes into making your order? If Sing Core is really such a unique and high-quality product, how is it made? Today, let’s dive into the process of taking a Sing Core custom door from concept drawing to finished door.

Step 1: Quote

The first step to any Sing Core door is to request a quote. You can do this by clicking the orange “Pricing” button in the top right corner of most of the pages on our website. This will take you to our order form where you will need to provide the details of your job. These include measurements, door style, use, and more. From there, your completed form gets sent to our sales team, who process your request and reach out to you with a quote. Sometimes they’ll ask for more information, but by the end of this conversation you’ll have a price and date of completion estimate.

Step 2: Shop Drawing

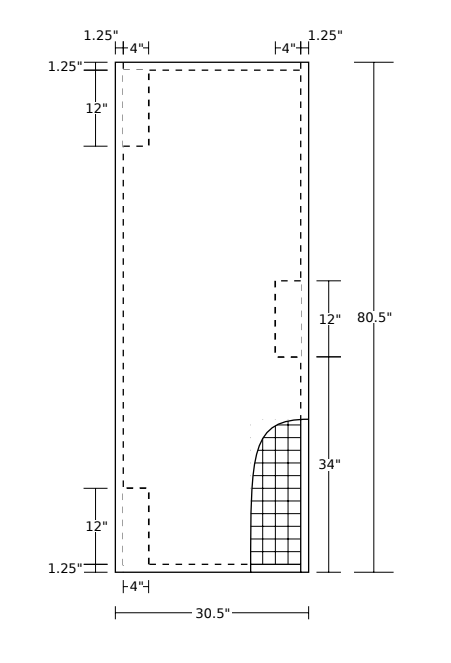

After you accept the quote and decide to move forward with your order, it gets sent off to the production team. The production team starts by making a shop drawing, which is a detailed drawing of your order, showing the exact measurements and shape needed to make your door a reality. The shop drawing is sent to you for one last round of approval, and then it gets put in the factory’s queue to be made.

Step 3: Building

Finally the time to actually make your order has arrived! The factory team starts by analyzing the shop drawing and making a plan for your door. Sometimes the plan is simple, but in some highly-customized-order scenario, there may be additional steps or materials needed. They then create the base of your door order: a Sing Honeycomb Core panel built to the specifications of your project. We use patented and patent-pending technology and designs to make this high end, lightweight, and incredibly strong panel. The panel is then framed and protected with high quality wood sheets, which completes your order. If you requested any additional features for your order, like in the case of a Sing Core Security Panel, then those added features would be added at various times throughout the process, depending on what they are.

Step 4: Wrapping Up

Next, we take your order and package it for shipping. This can vary in execution depending on some factors, such as size, location, and urgency. Many orders will have custom crates built to protect the panel during shipping if possible. The panel goes through one final inspection before being loaded up, and then you will be notified that your order has shipped.

Process Summarized

Your order goes through many stages to ensure quality and accuracy, and we work with you regularly to make sure we’re all on the same page when it comes to your custom order. All orders are appreciated equally at Sing Core, and we guarantee the same high quality, lightweight and sturdy product for everyone. In addition, you get our 50 Year Warp-Free and Structural Guarantee with every panel ordered.

Thank you for your interest in using Sing Core for your custom doors. If you have any questions, feel free to submit a quote request and our Sales team will be happy to assist you!