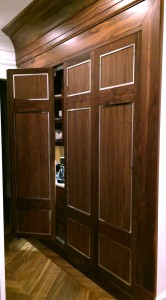

Your sliding door design is limited only by your imagination. Architects and designers love adding sliding doors to spaces for visual impact and improved functionality. Many options cover the landscape of design possibilities when considering adding sliding doors to a particular design. Some of the most popular sliding door designs include single sliding doors, double sliding doors, stacking sliding doors, pivot sliding doors, sliding barn doors, floating doors and pocket doors, just to name a few, while large sliding doors may comprise complete sliding walls and may be used as sliding room dividers.

Your sliding door design is limited only by your imagination. Architects and designers love adding sliding doors to spaces for visual impact and improved functionality. Many options cover the landscape of design possibilities when considering adding sliding doors to a particular design. Some of the most popular sliding door designs include single sliding doors, double sliding doors, stacking sliding doors, pivot sliding doors, sliding barn doors, floating doors and pocket doors, just to name a few, while large sliding doors may comprise complete sliding walls and may be used as sliding room dividers.

Imagine Your Sliding Door Design

The strength of contemporary architecture design is in the creativity limited only by the imagination of the individual envisioning the concept, look and feel of the project at hand. In a perfect world, your sliding door visualizations and ideas translate well to the real world. In many cases what is seen in the mind’s eye exceeds (sometimes far exceeds) the limitations of available building materials, time or budget constraints (because any sliding door design is possible given enough time and money).

Limitations of Sliding Door Design

When translating visionary sliding doors to the real world, certain limitations are imposed on those with their feet on the ground, whose responsibility it is to bring your sliding door dream to life. These limitations include such things as the Law of Physics and the specific characteristics of the available materials used to materialize your most exquisite sliding door design.

When translating visionary sliding doors to the real world, certain limitations are imposed on those with their feet on the ground, whose responsibility it is to bring your sliding door dream to life. These limitations include such things as the Law of Physics and the specific characteristics of the available materials used to materialize your most exquisite sliding door design.

Our team of best sliding door professionals have years of experience trouble-shooting and solving the problems associated specifically with unique sliding door designs. Here are some of the problems associated with sliding doors which we can provide solid solutions for (including our 50 year warp-free guarantee) regardless of the size, style or functionality of your sliding door design.

Sliding Door Sizes

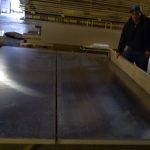

Sliding doors, just like any other type or style of doors, vary in accordance with the materials used and the overall size of the door which determines the weight of the door. Large oversized sliding doors, particularly those over 7 ft. tall are so entirely problematic that no door company will warranty them for more than one year because they cannot maintain optimum precision or door performance over time due to the sliding door’s mass. Yet, even large exterior sliding doors with SingCore inside can be fully guaranteed for 50 years not to fail, regardless of size (up to 50 ft.). So, now you can release the previous limitations concerning size and embrace the idea of very large sliding doors, even floor to ceiling sliding doors and sliding partition walls that will make your design shine for years to come.

Sliding doors, just like any other type or style of doors, vary in accordance with the materials used and the overall size of the door which determines the weight of the door. Large oversized sliding doors, particularly those over 7 ft. tall are so entirely problematic that no door company will warranty them for more than one year because they cannot maintain optimum precision or door performance over time due to the sliding door’s mass. Yet, even large exterior sliding doors with SingCore inside can be fully guaranteed for 50 years not to fail, regardless of size (up to 50 ft.). So, now you can release the previous limitations concerning size and embrace the idea of very large sliding doors, even floor to ceiling sliding doors and sliding partition walls that will make your design shine for years to come.

Sliding Door Weight

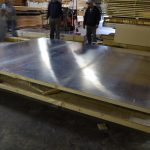

Sliding doors best operate within a delicate balance between size and weight, where weight can cause problems associated with the structure, the sliding door hardware, and the regular trouble-free operation of the sliding door. SingCore’s highly specialized staff can help to engineer doors to be lightweight (1/3rd or more the weight) of other solid core doors.

Sliding doors best operate within a delicate balance between size and weight, where weight can cause problems associated with the structure, the sliding door hardware, and the regular trouble-free operation of the sliding door. SingCore’s highly specialized staff can help to engineer doors to be lightweight (1/3rd or more the weight) of other solid core doors.

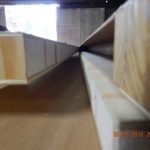

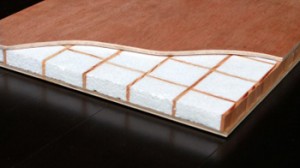

How do you make such a lightweight door? We use patented insulated Sing reinforced vertical grain torsion box core inside which makes the resulting door so much lighter than other solid core doors. Fore instance one door company replaced a series 25 foot tall sliding doors weighing in at 1,100 lbs. with Sing 25 foot sliding doors weighing in at a mere 198 lbs.

Sliding Door Hardware

Next up is the sliding door hardware, which is also most closely associated with the sliding door weight. In fact, the weight of the sliding door dictates which hardware is to be used. In the case of heavy sliding doors, heavy duty industrial sliding door hardware must be used. In the case of heavy sliding doors, the sliding door hardware can be the most expensive part of the sliding door design, costing many times the price of the sliding door itself. Also, regular use of a heavier sliding door will create maintenance problems with the sliding door hardware over time.

Sliding Door Warp

A warping sliding door is problematic in that it can not only compromise the operation of the sliding door itself but also can create additional strain on hardware and damage other surfaces which parallel the sliding door. In the case of a sliding door concealed within a cavity, like a pocket sliding door, a warped sliding door can become entirely inoperable.

A warping sliding door is problematic in that it can not only compromise the operation of the sliding door itself but also can create additional strain on hardware and damage other surfaces which parallel the sliding door. In the case of a sliding door concealed within a cavity, like a pocket sliding door, a warped sliding door can become entirely inoperable.

This is particularly common in wood sliding doors due to the nature of the natural wood grain; it moves. Even though wood grain is the most prevalent culprit in on site sliding door failures, sliding doors made of other materials may also warp as designers, engineers and contractors attempt to mitigate the problems associated with the weight of heavy sliding doors by creating a lightweight composite sliding door. Though the issue of weight is addressed, the strength of the door is only as strong as its sliding door core material. Therefore, lightweight composite sliding doors made of other materials besides natural wood are subject to failure due to warping also.

Sliding Door Solution

SingCore is the premiere one-of-a-kind solution to all problems associated with sliding doors, eliminating the challenges of:

WEIGHT – HARDWARE – WARP

While adding attribute inherit with having patented SingCore inside, such as

LIGHTWEIGHT – HIGH STRENGTH – INSULATION – WARP-FREE

And the Sing Core is only solution fully backed by our

50 YEAR WARP-FREE SLIDING DOOR GUARANTEE

Which includes full structure warranty for 50 years. No other siding door can do that, unless it has premium SingCore inside, helping not only to bring your sliding door designs to life but deliver to you and your customers the most insulated airtight lightest and strongest sliding door available today, guaranteed.

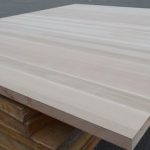

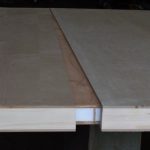

Recently, we have added our substrate only sliding door panels to our line of products, which could reduce your costs significantly. Customers love this option, because it allows them to apply their own skins, even glass or murals, veneer, wood staves, varnish, or primer and paint for a beautiful finish.

Recently, we have added our substrate only sliding door panels to our line of products, which could reduce your costs significantly. Customers love this option, because it allows them to apply their own skins, even glass or murals, veneer, wood staves, varnish, or primer and paint for a beautiful finish.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.