Patented Sing Core is bringing the latest development in lightweight and high strength technology to visit the cabinet industry. Imagine being able to use a lightweight building material that is commensurate with high-tech aerospace technology at 20 percent of the price.

Patented Sing Core is bringing the latest development in lightweight and high strength technology to visit the cabinet industry. Imagine being able to use a lightweight building material that is commensurate with high-tech aerospace technology at 20 percent of the price.

This new cabinetry alternative to MDF 4×8 sheets delivers many times the strength of solid MDF at a fraction of the weight with no headaches. Sing MDF cabinetry panels come in 4×8 and 5×12 sizes in convenient 3/4 inch thickness.

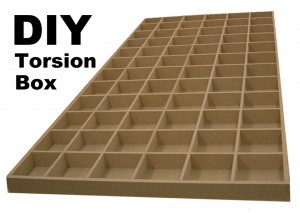

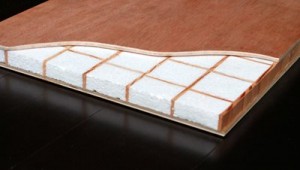

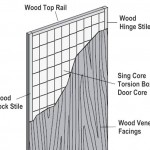

How are 3/4 inch Sing cabinetry panels made?

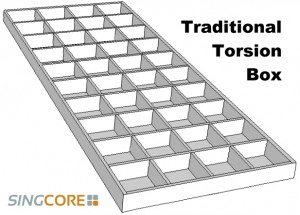

Start with patented Sing torsion box (2×3 inch grid size) where the voids are filled with recycled rigid foam insulation wall to wall with and sandwich it all between two sheets of 1/8 inch MDF and bond it altogether with formaldehyde-free adhesives for an Eco-friendly lightweight high strength composite MDF panels that out performs any other lightweight building material in terms of strength, weight and longevity.

Compare to other lightweight panel material

Compared to any other lightweight panel building material, like honeycomb panels made of paper honeycomb, aluminum honeycomb, cardboard, or even high-tech aerospace panels (costing five times as much per sheet) Sing 3/4 inch cabinetry panels are a bargain at twice the price.

Secret Ingredient Inside

The secret ingredient inside the Sing 3/4 inch cabinetry panels is the torsion box composite core that is the same product used by the US Navy and other high tech industrial applications where strength and weight are both considerations. This is the same technology used to build large doors – of any size or style – that can be guaranteed not to warp, bend, twist or otherwise fail for a full 50- years.

The secret ingredient inside the Sing 3/4 inch cabinetry panels is the torsion box composite core that is the same product used by the US Navy and other high tech industrial applications where strength and weight are both considerations. This is the same technology used to build large doors – of any size or style – that can be guaranteed not to warp, bend, twist or otherwise fail for a full 50- years.

Imagine having this material inside your cabinetry and/or furniture… Say, “goodbye,” to disposable furniture and heavy cabinetry which are highly desirable qualities sought in aircraft, marine and recreational vehicle platforms for both less weight and less maintenance over time.

Lightweight high performance cabinetmaking material

Even though plywood and particleboard are fairly standard fare in cabinet shops around the world, certain high end cabinet makers are seeking to embrace this new technology which is the perfect combination of old (torsion box) and new (composite) fine woodworking craftsmanship. Plus (as you undoubtedly already know) both plywood and particle board are heavy and prone to warp and rot; unlike Sing 3/4 inch torsion box cabinetry panels.

Structural integrity

The structural integrity of these hybrid cabinetry panels surpasses anything know in the affordable lightweight composite material and is increasingly finding its place amongst the transportation and general construction categories as an impressive upgrade alternative to plywood or other materials.

Built-in insulation

Sing composite cabinetry panels feature built in insulation (the rigid foam insulation filling the torsion box voids) that is a unique added feature whether you are building cabinets and/or other furniture.

Easy to work with

Standard woodworking tools are all that is required to take full advantage of Sing cabinetry panels, treat them just like you would any standard 4×8 piece of 3/4 inch panel.

Sing cabinetry panels are revolutionizing the industry as they are increasingly being found as a standard commodity in cabinet shops, millworks and furniture manufacturers throughout the United States and the world.

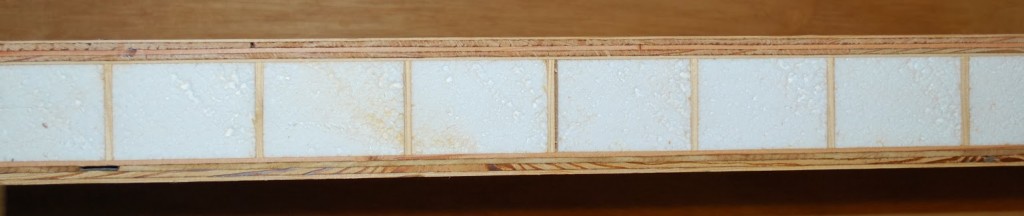

Edges

Sing cabinetry panels have unfinished (exposed, i.e. you can see the core) edges. This is easily remedied by adding edge trim, or closing the edge by any method desired. Also, the core material can easily be routered to accommodate insertion of wood implants where desired or necessary.

Simply CNC router out Sing Cabinetry Panels to insert any desired material.

Made in the USA

Eco-friendly Sing cabinetry panels are proudly made in the USA

- Lightweight MDF Bookshelves

- Over-sized insulated sing armoire with drawers

- Storage Cabinet Room Divider

Pictured to the right is a 1 ton truck on a piece of 1/4″ inch thick Hardy Plank wrapped around our Honeycomb core. it does not crack under the pressure of a 1 ton truck. This is the future economical, concrete home structure. The picture is proof. Can you drive a 1 ton truck over a conventional frame home wall without it cracking??

Pictured to the right is a 1 ton truck on a piece of 1/4″ inch thick Hardy Plank wrapped around our Honeycomb core. it does not crack under the pressure of a 1 ton truck. This is the future economical, concrete home structure. The picture is proof. Can you drive a 1 ton truck over a conventional frame home wall without it cracking??