Applications -> Building Components -> Doors -> Door Links -> Sliding Pocket Doors

Sliding and Pocket Doors

Products > Door > Sliding Door

Sliding/Pocket Doors

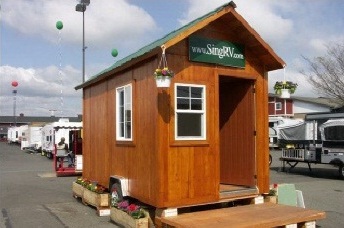

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

It’s so easy to use Sing Panels to make beautiful sliding doors of any size. Sing Door Panels have a ten year warranty for internal use. For external use, we offer marine grade plywood. If you need strength, lightweight, insulation, and true flatness, Sing has the answer!

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel. See our new C Series line of Affordable Barn Door and Sliding Closet Doors.

How to Buy

Sing Core door panels are easy to order. You may choose from our stock panels or order custom-sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day.

Custom doors without the custom pricing!

Sing Core door panels are available at a fraction of the price of conventional sliding door/pocket door panels. Sing Door Panels are insulated, lightweight, stronger and more dimensionally stable than solid wood panels – at less than half the price!

When using Sing Panels, you design your own door by adding the trim, paint, and hardware. Sing Core door panels are great for millwork shops and door manufacturers. Exclusive pricing is available to distributors and retailers.

Door Assembly Instructions:

You can combine these to make almost any size door you desire. Once your door panels have arrived, place them in the room where they will be installed and do the following:

1. Arrange your door panels on a level plane so that they can be joined precisely.

2. Join the panels in the horizontal position and applying glue in the grooved “biscuit” pocket.

3. Insert biscuit joint into one side of panel, apply glue to groove in second panel that will be attached to the first panel

4. Slide panel so that the other half of the biscuit is inserted into the biscuit groove and apply adequate pressure to the glued area. (We recommend formaldehyde-free, urethane glue)

5. Once all of the panels have been assembled together and the glue has completely dried, your Sing Core door is ready to install.

Check out the tutorial videos at the bottom of this page. Contact us if you have further questions/concerns on how to install our Sing Core door panels.

Order Custom Sizes:

To order custom door sizes, please submit a work order form. We’ll respond to you with a quote within two business days.

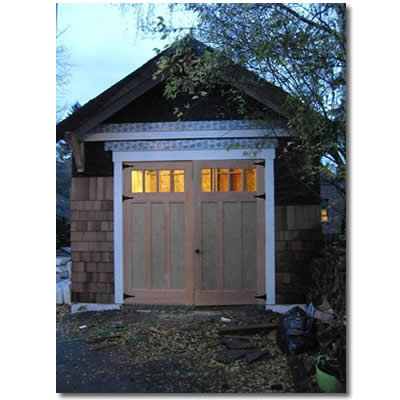

Installing a Sliding Factory Door

Step 1: Install the sliding door track.

Step 2: Prepare door for hardware installation.

Step 3: Install hardware and hang the door to make sure of fit and function.

Step 4: Finish and paint the doors.

Step 5: Admire your newly install Sing Sandwich Panel Sliding Doors.

Gallery | Technical Info | FAQ | Order Form | Standard Pricing

Case Studies

Title: Steam Room Door

Client: Pizza Company

Product: Sing Panels

Challenge:The client needed doors that resist moisture and close securely. He also needed the doors to withstand frequent use at a business.

Sing Solution:Sing Core doors are flat and straight enough to keep humidity from leaving the steam room. Water resistant coating was applied to protect the door, preventing it from warping and rotting.

Customer Quote:

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Title: Children’s Room

Client: Tremain Construction

Location: Washington State

Product: Sing Panels

Challenge: The family needed a large divider for their living room. It needed to be lightweight so that the kids could open and close it easily.

Sing Solution:Sing Core panels are light enough for a small child to move and easy to assemble. The family finished the doors with chalkboard paint to make it kid-friendly.

Customer Quote:

“As you can see, the photo below was taken right after install and finishing completed, still construction stuff in the area. The other picture is after the owners moved in and their kids started using the door, which is covered with blackboard paint; it becomes a moving mural in the space.” -P

- aluminum sing honeycomb lightweight non warping sliding door

- sing honeycomb lightweight aluminum sandwich

- glass sing honeycomb non warping sliding door

- honeycomb lightweight sandwich honeycomb door

- true flat sing honeycomb lightweight

- Sliding Barn Door Room Separation

- Bay of Large Storage Cabinets

- Contemporary sing honeycomb sandwich lightweight wood

- Sing honeycomb lightweight sandwich wood

- patented Sing honeycomb sandwich closet door

- Oversize Pocket Doors

- non warping strong honeycomb sandwich

- sing honeycomb lightweight glass sandwich

- oversize lightweight high strength honeycomb door

- large oversize lightweight high strength sing sandwich door

- lightweight high strength large honeycomb door

/dsc_0191_ew7m.jpg)

/dsc_0194.jpg)

/dsc_0199.jpg)