Applications -> Building Components -> Doors -> Solid Wood Blank Doors

Our panels make doors!

Patented Sing Core solid wood stave door blanks feature the newest technology in the door industry for composite doors yielding the only eco-friendly, lightweight, fully insulated, high-strength doors with wood blanks of any size (up to 40 ft.) that can be guaranteed true flat and to stay flat for 50 years.

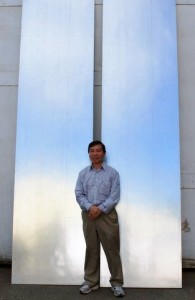

Large door versus regular-size door challenge (i.e., over 4 feet wide and over 8 feet in length):

Large doors are heavy, dimensionally unstable, require more strength due to the heavy weight, and are a challenge to manufacture, ship and install. High-end jobs require precision and true flatness to please the customer. A homeowner’s architect, general contractor and mill worker must solve the problem of warping doors. The solution to the challenge is to use patented professional true flat Sing panels to make your doors.

Sing Core wood stave door planks are the only solid wood doors that will not warp, bend, twist or cup following installation. This means no more continuous service calls for maintenance of big doors that cannot possibly stay straight due to the limitations of solid wood – or any other door core – that is subject to failure. Sing panels have a patented honeycomb/torsion box interior which gives lightweight yet unsurpassed strength (pound-per-pound stronger than steel) and stability to any door, and allows Sing Core to provide a 50-year guarantee

Sing panels make amazing designer doors in any style. With Sing panels, fragile doors such as French doors are made lightweight yet strong, not warping or breaking hinges, which will last for many decades.

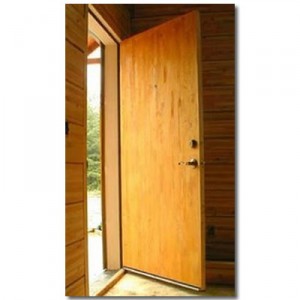

Sing panels make sturdy exterior doors in any style. With Sing panels, exterior doors are lightweight and strong, even when oversized. Our professional doors are guaranteed to stay true flat and not warp or twist for 50 years

The problem is that all door core materials are either not high precision, too heavy or will move when exposed to moisture, humidity or change in temperature resulting in door failure.

Heavy solid metal or steel will not warp, bend or twist, but is not high precision due to welding (sing core tolerance is + or – .006 inch!) and is often impractical due to the overweight issues causing excess strain on both the hardware and structure, causing continued maintenance issues. The solution is our patented lightweight yet strong Sing core technology.

Finishing a door blank:

There are two types of finish for door blanks: paint grade and wood grain. Paint grade includes such finishes as metal, Masonite, marine plywood, etc. Wood grain finish includes such finish as solid wood stave and thin veneer.

Why Use Solid Wood Instead of Veneer?

Never settle for substandard veneer doors again. Door engineers prefer to use inexpensive veneer as opposed to real solid wood facings because veneer is thought to be less likely to warp, bend or twist. But thanks to the super-strength of patented Sing Core technology, you can use solid wood stave and wood blanks with confidence knowing that your door can be guaranteed true flat and will stay flat.

How can a solid wood-faced door stay true flat? As every woodworker knows, when using a solid wood surface, the grain will move according to moisture or temperature change causing the door to fail. When using our patented Sing Core as a substrate you can safely use solid wood because the solid torsion box/honeycomb patented material is continually keeping the wood grain straight and true. Whereas wood stave has more wood fiber giving it more of a chance to warp than thin veneer due to the unbalance of the both side of the door moisture contents, patented Sing technology solves this problem by combining stiffing skin on both side of our patented Sing core. This Sing panel technology eliminates the troublesome movement of the door blank — warping is no longer a concern when wood stave is combined with patented Sing core.

In addition, solid wood is easy to work with, install (no need to hot press), repair and remodel. That’s why professionals trust Sing Core’s years of expertise in helping to design the only wood stave doors (that look just like solid wood doors) that can stay straight and true for many decades while respectfully honoring the beauty and elegance of solid wood, which far outlasts easily-damaged veneers, yet can be sanded and repaired if necessary.

Celebrate your real wood!

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize doors.

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize doors.

That’s why this technology is found everywhere, from beneath the sea (US Navy) to outer space (NASA) and everywhere in-between.

Sing panels may be finished in almost any wood species, like mahogany, redwood, teak wood, cherry wood, walnut wood, cedar wood, Ipe wood, sapele wood, poplar wood, ebony wood, ash wood, oak or any other hardwood or exotic wood types available.

This same wood blank composite technology is also a common solution for high-end projects like engineered hardwood flooring, shiplap, wood furniture, wood shelves, decking, shed doors or any other application demanding high precision and exemplary performance over time.

How is wood stave/veneer added to Sing panels?

How to Buy

To order Sing Large Door panels see our pricing page and submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Large Doors are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.