Sing Core and your Renovation

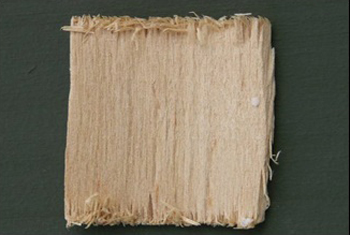

There’s no need to bother with the decision fatigue that comes with so many choices, because Sing Core is the best option when it comes to doors, bar none. With our lightweight and sturdy design, you can be confident that out product will stand the test of time. Not only that, it’s also durable and guaranteed not to warp, which is not something our competitors can claim.

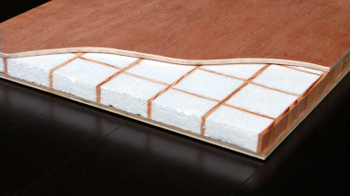

Using our patented honeycomb panel, architects and craftsmen around the country have been creating gorgeous additions to homes. Whether it be a pivot door, sliding door, or any other form of entry, Sing Core is the industry best when it comes to quality and durability. Just look at our long track record of success stories from satisfied customers, and you’ll see we hold up to our promise.

Not only that, but every Sing Core product comes with a 50 Year Guarantee, meaning in the unlikely event that your door does present any issues, we’ll make it right up to 50 years later. With this promise, you never have to worry about replacing your doors again.

What are the benefits of a Sing Core door?

What doors can I use Sing Core for?

Summary

Deciding to renovate your home or office is a big step. Sing Core is here to make that process smooth and easy, allowing you to spend less time worrying about doors and more time designing your dream space. With Sing Core doors, you are guaranteed to have an incredible, durable, and long-lasting feature that will never fail, and you will never regret.