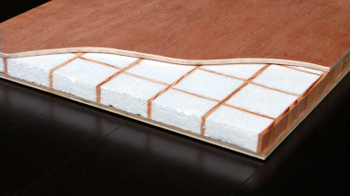

TRUE FLAT GUARANTEE

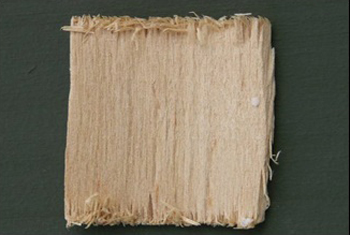

All composites including (but not limited to) Sing Core and aluminum (other materials may be added to the composite material) are guaranteed to be true flat and warranted to stay true flat under normal operation and in the form and function of the specified purpose and under the agreed upon conditions at the time of the creation of the material subject to the terms of our Limited Lifetime Warranty.

LIMITED LIFETIME WARRANTY

Sing Core products are warranted against defects in material and workmanship, and against rotting and decay for as long as you own and live in the Home in which the product was installed, provided that (i) it is installed without alteration and in accordance with applicable building codes and (ii) installed and caulked as specified by Sing Core’s installation instructions (iii) if exterior components are painted, the paint must have a LRV of 57 or higher.

The terms of this Limited Warranty excludes (i) weathering or discoloring of the unfinished material and (ii) warping or failures which are the result of or involve stress caused by localized application of heat, movement of building or building components, or expansion/contraction of building or building components.

TRANSFERABLE WARRANTY

The Warranty on the Sing Core unit is transferable by the original purchaser to one subsequent purchaser for purchaser’s personal residence provided Sing Core receives the Warranty Transfer Certificate within thirty (30) days after the date of transfer of ownership, and provided such notice is accompanied by a check or money order in the amount of $50.00 per home.

WARRANTY CONDITIONS

No warranty herein covers damages resulting from improper installation, abuse, accident, negligence, abnormal or unreasonable use (including failure to provide reasonable and necessary maintenance), improper or insufficient handling, storage, damage resulting from fire or lightning, windstorms, earthquakes, wind-borne objects, strain applied to the unit by movement of the building, inadequate provision for expansion or contraction of framing members, installation in ships or vehicles, installation outside the Continental United States, seal failure (if the seal has been subject to immersion in water), acts of God, any other components, parts, glass and labor provided by other parties, exposure to fire, corrosive fumes, condensation damage or any events or actions beyond the control of Sing Core.

This lifetime limited warranty does not apply with respect to (1) condensation damage due to high humidity or high vibration; (2) breakage of glass (other than clear glass).

The terms of this expressed warranty excludes failures due to damage due to freight carriers, common carriers, private transportation or any other means of transportation or handling after shipping from Sing Core.

The procedure for obtaining performance of the obligations of this warranty is as follows: if you believe your entry door to be defective, contact the contractor for inspection. If the contractor determines the Sing product or parts thereof to be defective, the manufacturer at its exclusive option will repair; provide a new product or part of a product after having determined that it does not conform to the limited warranties contained herein. The manufacturer reserves the right to discontinue or make changes in any of its products. If the products covered by this warranty are not available, the manufacturer shall have the right to substitute a product that is of equal quality or value. The manufacturer will ship the replacement product or part to the nearest authorized dealer and the purchaser must pay for any and all labor necessary to install such product or part and for the transportation from the nearest authorized dealer to his/her residence.

Any claim must be accompanied by a copy of the contract evidencing purchase of the Sing Core products.

SING CORE SHALL NOT BE LIABLE TO PURCHASER FOR CONSEQUENTIAL DAMAGES, SUCH AS, BUT NOT LIMITED TO, DAMAGES OR LOSS TO OTHER PROPERTY OR EQUIPMENT, LOSS OF USE, OR CLAIMS OF SERVICE INTERRUPTION, FOR BREACH OF ANY WRITTEN OR IMPLIED WARRANTIES ON ITS PRODUCT.

PURCHASER’S EXCLUSIVE REMEDY SHALL BE THE REPLACEMENT OF DEFECTIVE FINISH, COMPONENTS, OR PARTS, ALL AS PROVIDED HEREIN. IN ANY EVENT, THE LIABILITY OF SING CORE WITH RESPECT TO ANY CONTRACT, OR ANYTHING DONE IN CONNECTION THEREWITH SUCH AS THE PERFORMANCE OR BREACH THEREOF OR FROM THE MANUFACTURE, SALE, DELIVERY, RESALE, INSTALLATION OR TECHNICAL DIRECTION OF INSTALLATION, REPAIR OR USE OF ANY DOOR, COMPONENT OR PART COVERED BY OR FURNISHED UNDER THIS CONTRACT WHETHER IN CONTRACT, IN TORT, UNDER ANY WARRANTY, OR OTHERWISE, SHALL NOT, EXCEPT AS EXPRESSLY PROVIDED HEREIN, EXCEED THE PRICE OF THE DOOR, PART OR COMPONENT ON WHICH SUCH LIABILITY IS BASED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to purchaser.

THIS WRITING CONTAINS THE ENTIRE AGREEMENT BETWEEN SING CORE AND PURCHASER. DEALERS, CONTRACTORS, APPLICATORS, OR DISTRIBUTORS OF SING CORE PRODUCTS HAVE NO AUTHORITY TO GIVE WARRANTIES ON SING CORE’S BEHALF, THAT ARE DIFFERENT FROM OR EXCEED THOSE LISTED HEREIN. PURCHASER SHOULD THEREFORE EXAMINE THIS WARRANTY CAREFULLY.

ALL WARRANTIES, WHETHER EXPRESSED OR IMPLIED, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE TERMS HEREOF.

Some states do not allow limitations on how long an implied warranty lasts; so the above limitations may not apply to purchaser.

This Lifetime Limited Warranty extends only to the Sing products which were originally installed in your Home or other structure originally and shall not be valid or enforceable if you cannot prove that the Sing products were so installed

Important Note: Keep your receipt of purchase and the receipt from the contractor who made the installation in your Home showing the date of installation and the address in a safe place.

This warranty gives purchaser specific legal rights and he or she may also have other rights which vary from state to state.

OBTAINING WARRANTY SERVICES

Before submitting a claim for warranty services, please see all of our help and resources available on our website. To obtain Warranty services, please call (360) 495-3577. Once a Sing Core representative validates your claim, an RMA or Return Merchandise Authorization will be supplied to you to include with the product to return. Items without an accompanying RMA will be withheld for up to 30 days, in which you will be notified on instructions for return and shipping. The shipping cost will be billed to you. Lack of payment will result in disposal of the withheld product without any duty to the customer or account.