How Sing Core supports contemporary architecture and brings original architectural doors to life.

Why Specify Sing Core?

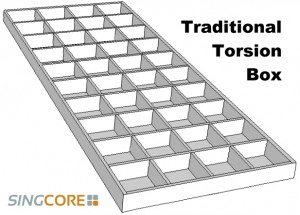

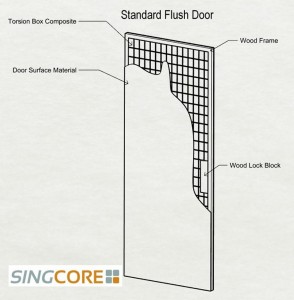

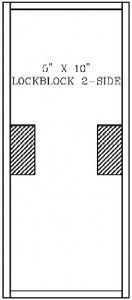

The primary reason top architectural firms specify Sing Core in their specs is for large doors because every door over three-and-a-half ft. wide or seven ft. tall is going to have a problem with warping, and Sing Core is the only way to build an Eco-friendly lightweight high strength fully insulated door which can be

Guaranteed Warp-free for 50 Years

This sets the bar extremely high, and when architects want to deliver the best for their particular high-end clientele, as specifying “Sing Core inside” elevates the project to an entirely new level.

Renowned for non-warping large doors, inventor Peter Sing’s patented and patent-pending building materials can do so much more. Next up on the list of reasons why architects seek Sing’s materials out for their upcoming projects includes lightweight dimensional stability and unsupported spans.

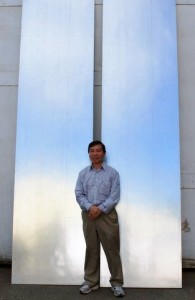

Here, Sing stands amidst a 13 ft. one-inch thick panel between two sawhorses, and you know if he were standing on any other building material, he would be standing on the ground. Yet, there he is suspended with little or no deflection. It boggles the mind, the possibilities of Sing’s core.

And Sing’s factory, located in the pristine forest region of the Pacific Northwest builds more than panels. He also builds posts and beams for use in other types of construction applications, which are just as lightweight and strong, if not stronger.

How Strong is Sing’s Core?

Independently tested, Sing’s core is 660 PSI, many times stronger when compared to any other lightweight honeycomb-type building material which usually clocks in at between 10 and 110 PSI.

That’s why you will find Sing Core inside impact doors. Sing says, “If you kick other doors, they will crash,

“Kick my door and you will break your leg.”

While lightweight and fully insulated, Sing Core is stronger that steel pound for pound.

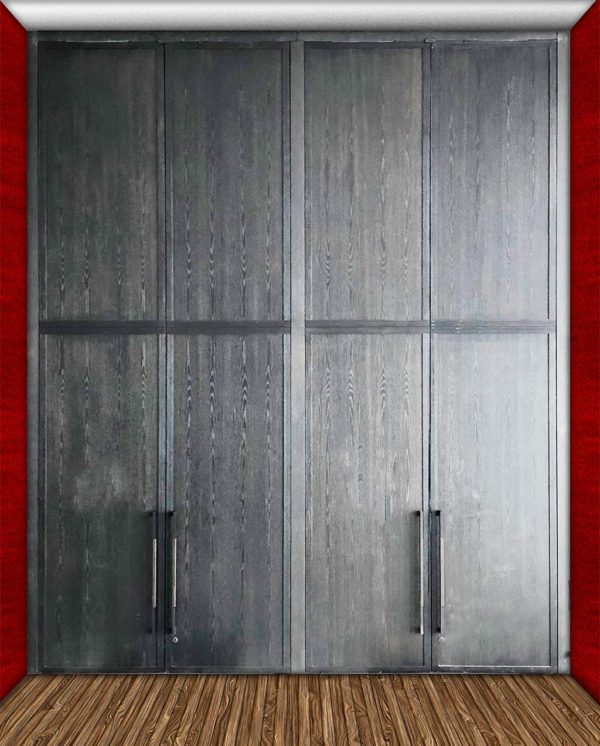

Architectural Lamination

When it comes to architectural designs using high precision lamination, Sing’s factory and his high precision laminating specialists provide top of the line results with unparalleled visual impact.

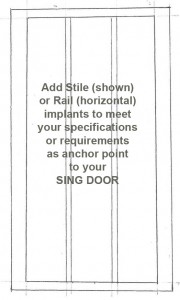

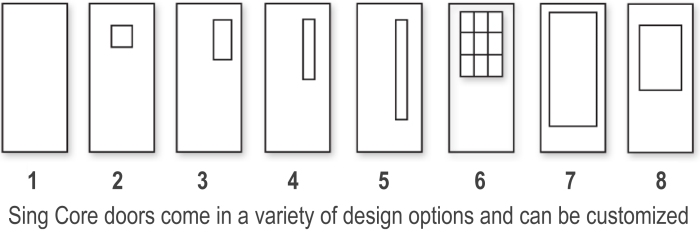

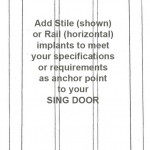

Laminates can be mixed and matched in any specified pattern, orientation, or specific shapes. In fact, Sing’s stile and rail surface lamination makes his high-end door blanks look like a high precision stile and rail door, for which he is well known for in the industry.

Sing’s lamination is also included in his no-fail 50-year guarantee.

Any Surface Material

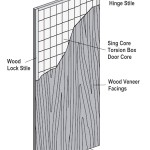

Due to Sing’s True Flat Team’s ability to keep any surface material straight and true, you will find them constantly hard at work designing the warp-free components to keep solid wood stave straight and true for 50 years, though their expertise is not limited to unstable wood grains.

Nearly any available flat building material can be incorporated with Sing’s core, including exotic natural wood grains, aluminum, brass, brick, bronze, cement, cold rolled steel, concrete, diamond plate steel, fiberglass, Formica, FRP, galvanized steel, hot rolled steel, HPL, Kevlar, Masonite, or stainless steel, just to name a few. That should get your creative juices flowing.

But there’s more

Any Size

Due to the incredible light weight of Sing Core and super strong resilience, the largest doors in the tallest buildings in the United States are built with Sing Core inside.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

You could find Sing Core from beneath the depths of the sea (US Navy) to outer space (NASA) and everywhere in between.

Any Application

There’s no doubt you will find Sing Core inside the finest oversized large doors, but you may find Sing’s core inside any item that is lighter in weight but expected to be used over and over again over a long life span.

100-YEAR FURNITURE

You will find Sing Core inside 100-year furniture (that’s furniture that is designed and built to last for a hundred years). This is in stark contrast to more popular inexpensive import furniture which is expected to be basically disposable.

You will discover new and varied ways to use Sing’s patented and patent-pending technologies for signage, floors, walls, ceilings, emergency shelters, modular work sheds, tiny houses, museum displays, store fixtures, and modular trade show booths which are designed to be knocked down and rebuilt over and over again for years on end.

A variety of travel industries are benefited by using Sing’s technologies, including, but not limited to hospitality, aircraft, aerospace, marine, rail, trucks, trailers, and RVs.

Even entire homes have built of Sing’s patented Sing Core.

See a wide range of Sing Applications.

Most Sustainability of Any Other Building Material

Peter Sing’s gift to the world is this highly sustainable product which can virtually last forever with little or no deterioration, and can be repurposed on the fly, making it possibly the most sustainable building material in the world.

Shouldn’t you be specifying Sing Core inside your most important projects?