Sing Core is the new space age composite material that is the affordable cousin to Balsa wood and has many features that Balsa wood does not have. Using the best combination of science and nature, patented Sing Core is a Balsa wood hybrid, using a natural vertical wood torsion box design.

Sing Core is the new space age composite material that is the affordable cousin to Balsa wood and has many features that Balsa wood does not have. Using the best combination of science and nature, patented Sing Core is a Balsa wood hybrid, using a natural vertical wood torsion box design.

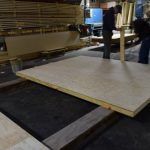

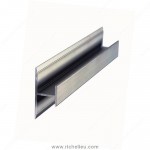

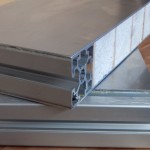

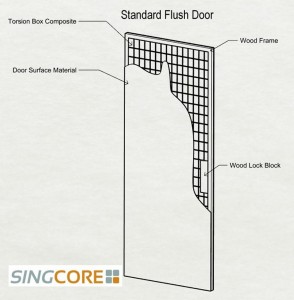

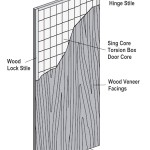

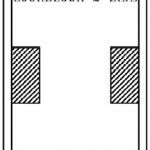

While torsion box has been used for centuries as lightweight structure, but Sing Core fills the open spaces with recycled foam (available in a variety of densities and material to meet your specifications), then the exterior surfaces (or skins) are bonded, completing the solid structure.

Weigh the alternatives and you can make an educated decision as to whether Sing advanced composites (the best of both worlds) will better suit your needs at less than one-third the weight of Balsa wood at less than half the price.

Balsa wood does have high compression, yet compared to other composite cores, Sing Core tests out at 660 PSI, that is stronger than steel pound for pound (even bullet proof doors don’t test that high). And Sing Core is more ecologically responsible as we use only 8% natural wood fiber (compared to balsa wood’s 100%) yet due to its unique design is much stronger when compared to other materials.

Unlike Balsa wood, Sing Panels are resistant to warp, twist and rot, and they are pre-insulated for insulation and sound-deadening.

Unlike Balsa wood, Sing Panels are resistant to warp, twist and rot, and they are pre-insulated for insulation and sound-deadening.

And Sing Core is so much more affordable than balsawood, especially if you are considering incorporating it as a lightweight substrate material for a large project, like a door, a table top, conference table, etc… See more applications.

Sing Core’s built-in torsion box structure, where the grid voids are not left unfilled but are filled with EPS foam provides a solid surface for bonding exterior building materials to that will not delaminate over time. Upgrading to closed-cell foam, makes Sing Core a perfect match for marine applications, like decking materials.

Sing Core Compared to Balsa Wood:

| Sing Core | Balsa Wood | |

| Oversize? | Yes | No |

| Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length. | ||

| Affordable? | Yes | No |

| Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core. | ||

| Insulation? | More | Less |

| Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications. | ||

| Sound deadening? | More | Less |

| Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request. | ||

| Waterproof upgrade? | More | Less |

| Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements. | ||

| Fire retardant upgrade? | Yes | No |

| When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative. | ||

| Bullet-proof upgrade? | Yes | No |

| In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core. | ||

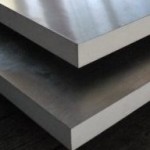

| Thickness available? | Yes | No |

| Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available. | ||

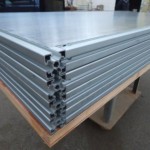

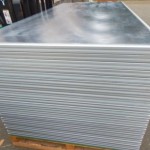

| Skin options? | Yes | No |

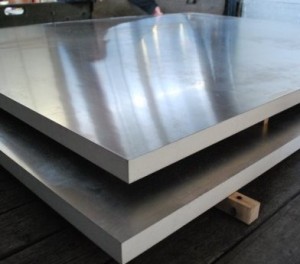

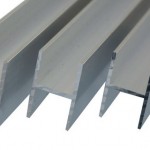

| Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc… | ||

| Easy to machine? | Yes | No |

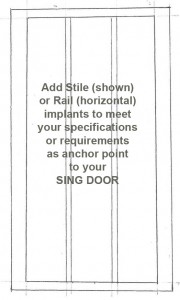

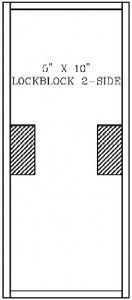

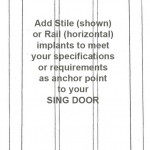

| Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening. | ||

| Fast turnaround? | Yes | No |

| In you’re in a rush, only Sing Core can be custom made within 1 week hours and is proudly manufactured for you in the USA. | ||

Sing Core is the basis of the Sing Sandwich panel, Sing Panels and Sing Post and Beam, with which you can solve most any structural challenge especially in terms of lightweight, high strength and Eco-friendly building materials, guaranteed.