Welcome to SingCore, where innovation meets collaboration to redefine interior spaces. Our pocket doors are not just a solution; they’re a partnership. Tailored exclusively for millworks, architects, and contractors, SingCore offers a seamless blend of elegance, efficiency, and reliability. Explore the world of SingCore pocket doors, designed for professionals who demand excellence.

Why SingCore Pocket Doors for Professionals?

1. Collaboration with Industry Experts:

SingCore exclusively collaborates with millworks, architects, and contractors, understanding the unique requirements of professionals in the field. Our doors are not just products; they’re a result of a partnership that prioritizes the specific needs of those shaping spaces.

2. Precision Craftsmanship:

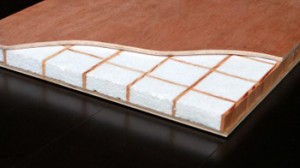

Our commitment to precision craftsmanship sets us apart. The core of our pocket doors features patented Sing honeycomb panels, ensuring a lightweight yet sturdy design. This commitment to excellence in materials and construction guarantees doors that stand the test of time in both form and function.

3. Comprehensive Design Options:

Tailor your projects with our extensive range of design options. From classic wood veneers to sleek glass panels, SingCore pocket doors provide versatility to match the unique aesthetic preferences of your clients. Custom designs are also available, allowing you to create spaces that are both functional and visually stunning.

4. 50-Year Warp-Free Guarantee:

SingCore takes pride in offering an industry-leading 50-year warp-free guarantee. We stand by the quality of our pocket doors, ensuring that they maintain structural integrity for decades to come. This guarantee is a testament to our commitment to providing professionals with reliable, long-lasting solutions.

5. Exclusive Collaboration Process:

Working exclusively with millworks, architects, and contractors, SingCore understands the importance of a streamlined collaboration process. Our dedicated team is here to support you every step of the way, from design conceptualization to project completion.

6. Quiet and Effortless Operation:

Experience the tranquility of spaces with our pocket doors, engineered for quiet and effortless operation. The precision of our hardware ensures a smooth glide every time you open or close the door, enhancing the overall user experience for your clients.

Elevate your projects with SingCore Pocket Doors – a partnership built on precision, reliability, and exclusive collaboration. Join the community of professionals who trust SingCore to deliver exceptional results. Explore our options and redefine interior spaces with confidence.

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:1280)