Monday, July 18, 2013 For Immediate Release

|

The first container of green patented plywood exported to Asia is the start of something new. Inventor, Peter Sing from McCleary, Washington, invites Americans to join his grass roots eco-revolution.

|

This might be the first container of a new, lightweight plywood manufactured in the United States of America’s Pacific Northwest exported and received in Bangkok, Thailand.

In a world where little is exported to Asia, especially in the way of wood products, like manufactured plywood because the end product can be manufactured more inexpensively outside the USA, it is interesting that one American company would find an open market in Asia.

Why would Asia import this particular product from the United States?

Why would Asia import this particular product from the United States?

These finished panels are extremely unique and meet increasing demand for new manufacturing standards being adopted overseas and are now seeing the light of day in America.

The first concern is that the construction industry is seeking more eco-friendly, sustainable solutions for building projects.

In this case, one of the tallest buildings in Bangkok was seeking to find a solution that met the biologically sound agenda with superior strength. The solution to the problems faced by the Thai engineers was discovered using a simple Google search for “lightweight panel” solving not only the ecologically friendly problem, but was also extremely lightweight, super-strong and has a longer lifespan than similar plywood-type products.

The patented Sing Core honeycomb panels were manufactured under the guidelines and supervision of inventor, Peter Sing in McCleary, Washington, who also holds the patent on the Sing Core technology.

According to Inventor Sing, “Sing Core honeycomb panels are lighter weight than paper-core products; stronger than any material including titanium with the same size honeycomb grid for maximum compression; made using less energy and raw materials and less waste than any other similar materials; are manufactured from natural and recycled materials that are renewable and earth friendly… plus,” says Sing, “In a society that has become accustomed to most everything being inexpensive and disposable, we provide Sing Core as a solution that will last for centuries.”

While Asia has been accused recently of dumping plywood solutions (providing under cost in order to decimate the market) to the Americas, resulting in a mandatory 25% duty to offset their economic impact on domestic products, the American-made Sing Core solution is launching a grass roots revolution to return pride to the United States, while providing local jobs, supporting local communities and economies while reducing the greenhouse effect at home.

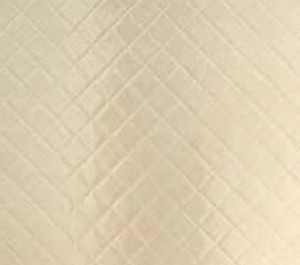

The unconventional strength is achieved by Sing’s patented design utilizing a vertical-grain wood honeycomb filled with a foam core, that when sandwiched between two laminates is 10-times the strength of traditional plywood solutions, maintaining straightness or flatness over a large span of material.

This project represents less than a tenth of one percent of the solutions that Sing Core technology provides. Peter Sing says, “Sing Core can be used in thousands of applications from furniture manufacture to huge structural challenges. One practical application that we are known for in the USA is for large doors, because ours are so lightweight, stronger and more eco-friendly than anything pound-for-pound and maintain their integrity while lasting hundreds of years.

This project represents less than a tenth of one percent of the solutions that Sing Core technology provides. Peter Sing says, “Sing Core can be used in thousands of applications from furniture manufacture to huge structural challenges. One practical application that we are known for in the USA is for large doors, because ours are so lightweight, stronger and more eco-friendly than anything pound-for-pound and maintain their integrity while lasting hundreds of years.

“We supply to the companies that build products for the President, Statesmen, Prime Ministers, Kings and the Pope, because,” Says Sing, “This is the only eco-friendly solution that solves all the problems of oversize integrity, strength, lightweight and will pass the test of time.” Although high-end clients are currently using this technology, Sing says he wants to bring it to every household stateside; then he plans to take his invention to the rest of the world.

Sing core is an improvement over existing wood components due to its use of less than 10% wood product with the grain perpendicular to the surface of each panel to form the honeycomb matrix sandwiched between two skins of any desired material; it is this design problem/solution that led to the development of his invention which Mr. Sing expects to be a common household name used to describe a new level of quality standard in manufactured products.

Sing Core technology can be applied to nearly any building material including (but not limited to) concrete, metals, fiberglass, plastics, even bulletproof skins can be used, like Kevlar.

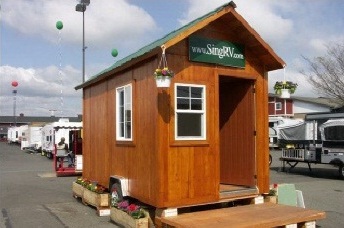

Inventor, Peter Sings, wants to take his patented technology to the streets in a grass roots revolution to support working class America, as well as manufacturing facilities across the United States via his virtual training facility, “Lightweight University.” The intricacies and possibilities of Sing’s patented innovations can be shared on an equal platform by participating Americans, whom Sing regards as “consultants” rather than students.

The University is open to all Americans who want to help us build a more sustainable future while shoring up local economies. He says, “Of course the University is open to the manufacturers that we work with, but they are large corporations. My goal is to put this technology into the hands of the people, to put them to work so that they can support their families while making the world a better place.” In making his program available to, “everyone,” he is offering scholarships to those who might need a helping hand in embracing these technological advancements.

Sing explains, “I want to help the one-man operations, mom-and-pop shops and small businesses get back on a profitable track in life and help them achieve a better bottom line by producing products that are superior quality, at a lower base cost than conventional materials, including, scholarships, grants and subsidies for Sing Core for low-end solutions enabling them to compete with lower-quality inexpensive import products.”

Sing explains, “I want to help the one-man operations, mom-and-pop shops and small businesses get back on a profitable track in life and help them achieve a better bottom line by producing products that are superior quality, at a lower base cost than conventional materials, including, scholarships, grants and subsidies for Sing Core for low-end solutions enabling them to compete with lower-quality inexpensive import products.”

What does it take to start up a Sing Core manufacturing facility? Peter Sing answers, “It’s easier than you think. We show you how to set up your manufacturing facility in less space than a single car garage, how to make your own Sing Press with our materials; and we even supply our students with Sing Core at their location on consignment. That means they only pay for the product that they use, as they use it, on demand.”

And it takes less time to learn this new green technology than you might think. Sing explains, “There is no need to go to school for four years to get a job. I can show you how to do this in two weeks, and I will even give you the material that you need to get started.”

For more information, visit: http://www.singcore.com and/or http://www.lightweightuniversity.com respectively.

Contact: Peter Sing

Sing Core

P.O. Box 1691, McCleary, WA 98557

info@singhome.com

360-495-3577