1-2 Sing Core vs. Other Cores

1-2 Sing Core vs. Other Cores

Compared to other material Sing Core is possibly the most significant Eco-friendly, renewable structural advancement in the last century increasing the strength and reducing the weight of any solid structural material.

When compared to solid material, Sing Core:

- uses less solid material

- environmentally sound

- structurally stronger

- lasts longer

- less expensive than most solid material

- easier to work with

The conclusions in the following chart are based on our independent analysis. If you do not agree with any comparison results, please let us know. If you agree that these conclusions are accurate, please share this with your friends to help us build a better, more sustainable world. |

Sing Core Comparisons Based on 2″ x 2″ Grids

|

Sing Core |

Foam |

Aluminum |

Balsawood |

Nomex |

Plastic |

Cardboard |

| Insulation |

✓ |

✓ |

x |

x |

x |

x |

x |

| Sound Deadening |

✓ |

✓ |

x |

x |

x |

x |

x |

| Lightweight |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

x |

| Strength |

✓ |

x |

✓ |

✓ |

✓ |

x |

x |

| Solid |

✓ |

✓ |

x |

✓ |

x |

x |

x |

| Eco-friendly |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Renewable |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Oversize |

✓ |

x |

x |

x |

x |

x |

x |

| Dimensionally Stable |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

| Affordable |

✓ |

x |

x |

x |

x |

x |

✓ |

| Waterproof Upgrade? |

✓ |

✓ |

✓ |

x |

✓ |

✓ |

x |

| Fire Retardant Upgrade? |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

✓ |

| Bullet-proof Upgrade |

✓ |

✓ |

x |

x |

x |

x |

x |

| Thickness Available |

✓ |

x |

x |

x |

x |

x |

x |

| Skin Options |

✓ |

x |

x |

x |

x |

x |

x |

| Easy to Machine |

✓ |

x |

x |

x |

x |

x |

x |

| Fast Turnaround |

✓ |

x |

x |

x |

x |

x |

x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Even though Sing Core is less expensive than most solid material, the end result is more structurally sound, lightweight, will not compromise over time and reduces the amount of man-hours and equipment to install.

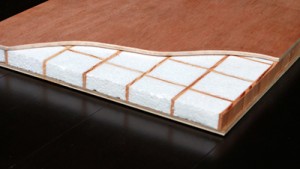

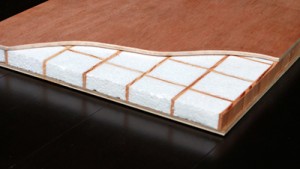

Sing Core is a honeycomb sandwich panel composite material with built in structural grids. Sing Core could have the exterior surface skin of any material including, but not limited to wood (seen in photo), metal, plastic, glass, Kevlar, even concrete and cement. The strength of our design is due to the structural grids made of naturally abundant, renewable, vertical grain veneer wood fiber. Sing Core is constructed in a fashion similar to torsion box technology most commonly found in the aeronautics and space exploration industries.

This technology is what allows our panels remain strong, lightweight, and flat without denting, cracking, and warping. See a comparison here. Inventor Peter Sing uses this torsion box technology, along with wood fiber and foam to create patented Sing honeycomb core: the incredibly strong, true flat, lightweight, renewable composite material of the future. Check out our products section to see a few different applications.

Engineering Myth-busters

- Heavy is not equivalent to strong

- Lightweight is not equivalent to weak

- Expensive material does not ensure high function

- Solid material is overused and not ecologically responsible

Most construction is a waste of materials, natural resources and has a negative impact on our planet. Solid materials are overused in an attempt to increase the strength or lifespan of the project. This excess of materials and resources is not necessary… and can be likened to killing a fly with a machine gun.

It may be hard to believe, at first, but for the first time in our history, a truly responsible structural alternative can be found in Sing Core technology. Many of our clients were skeptical when they queried us about our lightweight and strong solutions to their design challenges.

That is why Sing Core is the secret ingredient found in the homes, offices, estates and showrooms of royalty, political and religious high-end environments. Once you try the Sing Core alternative, you will never go back to traditional building materials in some cases.

Traditional honeycomb panels have come to the rescue addressing the lightweight needs of industry. Sing Core is compatible to (if not well out-performing) most honeycomb technology in terms of weight, but no other honeycomb core can compare to Sing Core in terms of strength. None.

Before today, you did not know about Sing Core’s environmentally responsible solutions to function and sustainability. Now that you do, what will you do with that knowledge?

Take the Sing Core challenge.

Sing Core is a patented technology that uses a unique honeycomb core and high quality materials to create lightweight, sturdy, and high-strength panels that are perfect for luxury doors and high-end homes. Unlike traditional building materials, Sing Core is highly customizable, allowing architects to create unique and visually stunning doors that stand out from the crowd.

Sing Core is a patented technology that uses a unique honeycomb core and high quality materials to create lightweight, sturdy, and high-strength panels that are perfect for luxury doors and high-end homes. Unlike traditional building materials, Sing Core is highly customizable, allowing architects to create unique and visually stunning doors that stand out from the crowd. In addition to their lightweight nature, Sing Core panels are also incredibly strong and durable, making them an ideal choice for high-traffic areas. Sing Core panels can withstand heavy use without warping or bending, ensuring that the doors maintain their shape and function for years to come. In fact, all of our professional panels come with a 50 Year Warp-Free and Structural Guarantee, so you never have to worry about the effectiveness of your design.

In addition to their lightweight nature, Sing Core panels are also incredibly strong and durable, making them an ideal choice for high-traffic areas. Sing Core panels can withstand heavy use without warping or bending, ensuring that the doors maintain their shape and function for years to come. In fact, all of our professional panels come with a 50 Year Warp-Free and Structural Guarantee, so you never have to worry about the effectiveness of your design. Sing Core panels also offer superior soundproofing capabilities, making them a popular choice for luxury homes and high-end buildings. The panels’ unique design helps to absorb sound, reducing noise pollution and creating a quieter, more peaceful environment for residents and occupants.

Sing Core panels also offer superior soundproofing capabilities, making them a popular choice for luxury homes and high-end buildings. The panels’ unique design helps to absorb sound, reducing noise pollution and creating a quieter, more peaceful environment for residents and occupants. Lastly, Sing Core panels are an environmentally friendly option, made from sustainable materials and in a no-burn factory. This makes them a smart choice for architects looking to create sustainable, eco-friendly buildings that are both functional and visually stunning.

Lastly, Sing Core panels are an environmentally friendly option, made from sustainable materials and in a no-burn factory. This makes them a smart choice for architects looking to create sustainable, eco-friendly buildings that are both functional and visually stunning.

As temperatures begin to rise, many homeowners struggle to keep their homes cool and comfortable. High energy bills, drafty doors and windows, and inefficient air conditioning systems can all contribute to a hot and uncomfortable living environment. Fortunately, there is a solution that can help keep your home cool and comfortable all summer long – Sing Core door panels.

As temperatures begin to rise, many homeowners struggle to keep their homes cool and comfortable. High energy bills, drafty doors and windows, and inefficient air conditioning systems can all contribute to a hot and uncomfortable living environment. Fortunately, there is a solution that can help keep your home cool and comfortable all summer long – Sing Core door panels.