Mirrored Carriage Doors

Mirrored Carriage Doors

I FINALLY just had my facing finished! AAAAHHHH. I think they came out pretty great. I designed the face I wanted and gave it to my guy. He found some reclaimed cedar from an old garage and put it on and milled the rest. I didn’t want to chop holes, so I created the illusion with mirror. I think they came out Fantastic and they hardly weigh a thing. Thanks again for your help and great doors. Now I just have to paint the molding and it will be finished!

Cecilia Story

The Nature Conservancy

“Peter and Linda along with the rest of the Sing Home team were lifesavers! They were wonderful to work with and did all that they could to meet tight deadlines without losing the flawless quality in their work. I look forward to collaborating with them again.

All the best,”

Jane

See display here

http://www.ink-dwell.com/

Robert Drake

“I am a returning customer of yours from last year. I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.”

Robert Drake

Robert Drake Construction:

Yes, your doors were exactly what my client was looking for and no one else in the county had them. Please feel free to give my name, cell phone number, email address and any other information you want to your potential customer. They are welcome to call anytime.

Sincerely,

Robert Drake

Robert Drake Construction

Bruce Kimmel

125 Year-old Church Door Replacement

These doors were replacements for original doors on our 125-year-old Church in a historic village in upstate NY. The size of the doors were quite unique, so buying premade door slabs was not an option, and custom doors were well outside of our budget. For the cost we were quoted for one set of doors, we were able to build and hang all 3 sets with the end product being a good reproduction of the original solid doors.

The Sing Core panels allowed us to get an insulated door, in our custom size, and I was able to apply 1X lumber and trim on both sides which allowed me to recreate the look of the original stile and rail look of the existing doors. The panels were straight and flat, and made a great substrate for the trim. We painted the outside in the traditional red color common on Methodist churches, and stained the inside to match to paneling in the vestibule.

Bruce

“Thanks for the follow-up, I’m very pleased with the panels an how they have worked out with my project. As you can see, I framed them with poplar molding, glued in place with waterproof glue, and painted them to seal against the weather.

I brag on these panels all the time and everyone is always impressed.

Thanks again,”

Steve

“Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.” Amy

“ I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.” Robert D.

“I love your product!” Kevin B.

—

“Your product is the bomb diggity!” Smithy D.

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Chad Thompson

Trellis Interiors

Sing Homes,

Of course, please feel free to give them my name and cell phone.

Thank you,

Chad

You bet! We love your doors!!

Regards

Dewey

Direct quotes from recent customer:

What did you think of the panels when they arrived?

They looked just as I expected. High quality workmanship and to my

exact specifications.

What was it like working with them to get the design you wanted?

Very easy to work with. The panels were totally flat and square.

What did you think of the panel’s weight in comparison to their size?

Weight came in as expected which is very light compared to a solid wood

door.

Do you think that our garage door panels are equal in strength to

standard garage panels?

I think these panels are stronger than standard garage doors.

Definitely stiffer.

If you were to do another project similar to this would you buy our

garage door core panels again?

YES.

Would you tell other people where you got your door cores from?

YES.

Please tell us in your own words about your experience with our panels.

I have nothing to complain about with regards to the entire

experience. Customer service while ordering the doors was top notch.

Price was great. Shipping/delivery was easy. Fabrication of my doors

was straightforward.

-Kevin B., California

—

Thanks for getting in touch.

Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.

If you are interested, i think you could market this product to artists.

I don’t think there is anything on the market in terms of oversize drawing boards.

Thanks again.

Amy

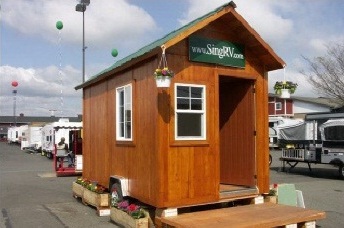

A Testimonial from Dave Kellog – Dave Kellog is the first Sing Home customer to build in Wyoming. He’s beginning with a 24′ x 36′ multiple use cabin, and will later add a large Sing Timber residence. Dave writes:

“The project is going extremely well… the building is 24′ x 36′, and after the foundation and floors were poured, I got to wall height (10’3″) in just seven days… All work has been completed by me alone…so this has been a one person operation. I have had a lot of interested folks stop by, all very curious about the Sing Timbers. I think when I get the house and garage built, I may spec one just to see how well it sells! It has been a lot of fun so far, just like building with big Legos, and boy is this thing solid! I really like the Sing system, it is wonderful for ‘do it yourselfers’, especially if it is only yourself doing it!”

Dave Kellog

Lander, Wyoming

A Testimonial from Bob & Linda Freeman – The Freemans built two Sing Homes, a 24′ x 24′ cabin w/ garage, and a 2000 s.f. prow front home. They write:

“We built the garage/bonus room last year because our home in Bellingham was still for sale. We wanted to see if Sing Logs was what we really wanted. It turned out better than we thought it would. They are easy for people who know nothing about construction work. They look great and the logs are very strong…stronger than conventional post and beam. How do we know? We are now building the house attached to the garage and I had to cut the door opening. It was really difficult to knock the door out, even after it was cut with a chain saw! The logs also make the interior quiet, and through the winter, it was toasty warm with just a propane stove.”

Bob and Linda Freeman

Mazama, Washington

Chuck Dudley – Pioneer Home Services – I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up.

I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up in the Spring. After having built with their product, I do not want to build again using conventional framing. There simply is no comparison in quality, stability and strength, longevity, energy efficiency, or beauty. The cost is comparable to a custom stick-built home, but with so many more advantages. There is also a financial advantage with a Sing Home. As soon as the home is completed it can easily be worth more than a third more than it cost to build. Can I recommend a Sing home? Absolutely I can! I stake my reputation of 35 years in construction on the Sing Home product. Chuck DudleyPioneer Home Services

Here is a butcher block table top we made custom for a client, the beauty of the product speaks for itself!

It’s so easy to use Sing Panels to make beautiful

It’s so easy to use Sing Panels to make beautiful

/dsc_0191_ew7m.jpg)

/dsc_0194.jpg)

/dsc_0199.jpg)