Pricing for Homeowners

Pricing for Homeowners

Many educated homeowners demand that their trade professionals use Sing Core products in their home projects. (See our Homeowner’s page for more information.)

Regrettably, we are unable to provide patented Sing products for retail or directly to homeowners as we only support architects, millworks and door companies. See full apology.

If you do not have a millwork or door company in mind, please check out this online map to help find one near you.

Note: We do not sell complete finished doors to retail customers. No hardware, no finishing. We only support other trade professionals, like millworks and door companies who make doors with Sing Core inside look beautiful and perform elegantly. If you are a retail customer, please contact your architect, designer, contractor, door company or millwork and tell them you want, “Sing Core inside.”

To Get Sing Core in Your Home

- Know what you want

-

-

- Have at least an idea or drawing of what you want

- Determine how many and what size of panels you will need for your project

- Know what exterior material you want on your panels

- Congratulations!

- You are the proud owner of your new completed project that is

- Eco-friendly

- Lightweight

- High-strength

- Insulated

- High-performance (non-warping true flat doors, walls, furniture, etc…)

- Will last longer than anything made with any other material with these benefits

- Decide how you will manufacture your project

- Seek out a professional

- Architect, Designer, Design/Build, General Contractor, Mill Work, etc…

- Give them your drawing

- They will deal directly with us.

Since Sing Core is a manufacturer, we do not provide customer support for retail clients. If you are looking to build a tiny house, carriage door, etc., please seek out qualified trade professionals (such as architects, general contractors, mill-works, door manufacturers, and woodworking professionals) for help using Sing Core products for your project. Sing Core is the manufacturer of our patented invention and as such we are not qualified or staffed to teach all the uses for, or handling of, Sing Core building materials.

Sing Core does make the best reinforced structural insulated panels (RSIP) for use in applications such as walls, floors, ceilings and roofs; however, we offer no support or training or guarantee for unskilled users of Sing Core products.

For more information click Tiny House, No Permit for 800 sq. ft. Houses.

Home Owner Resources:

Sliding Doors for Homeowners

Take a look at some Sing Homes (made entirely of Sing products)

LEARN MORE…

SING CORE GRADES:

Sing products are available in your choice of three formats to accommodate your specifications and expectations:

Standard: The strongest, lightweight Eco-friendly building material invented

Professional: Specially formatted for non-warp performance and guarantee

Hot Press Ready: Hot-press-ready (for thin veneer)

SING CORE GRID SIZE:

Our grids come in small, medium and large sizes.

INSULATION VALUE:

R-value 3.5 (EPS foam)

R-value 5.7 (urethane foam)

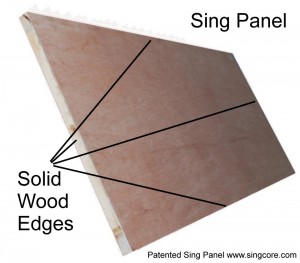

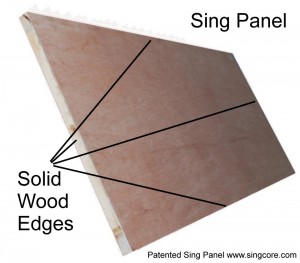

SOLID WOOD EDGE AND LOCK BLOCKS (HARD POINT):

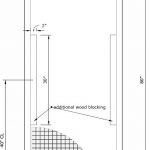

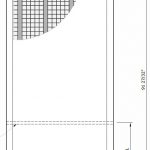

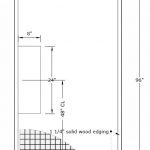

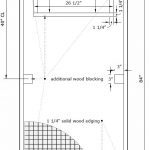

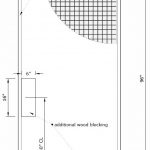

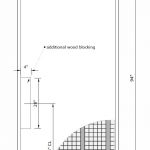

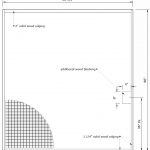

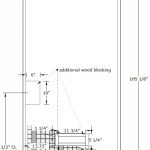

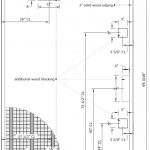

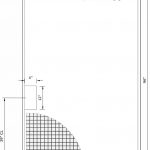

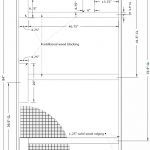

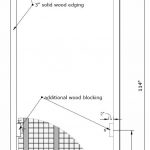

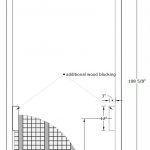

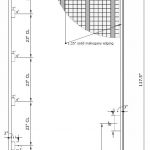

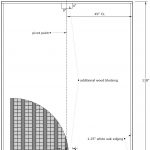

Customizing options that can help make your order more specific are size and location of internal wood (or other specified material) such as implants, stiles and/or rails (solid wood edges on 4 sides of the Sing panel) and lock blocks or nailing for added siding over the surface of the Sing panel. The best way to show us what you need is to by provide us with a simple drawing to show the location of hard point.

SKIN CHOICE (SURFACE MATERIAL):

There are many options for Sing Core panels. (See: Material Options)

Paint Grade: 1/4 inch or thicker plywood, mdf, Masonite

Metal: .20 inch to .125 inch aluminum, cold rolled steel, galvanized steel, hot rolled steel. HPL, FRP

Wood Grain: Thin wood veneer .020 inch on top of .125 inch mdf over top of aluminum Sing panel

Wood Stave: .125 inch applied over the top of aluminum the Sing panel substrate or on top of the .125 inch mdf over the top fo the aluminum Sing panel

Skin: There are many options for Sing Core panels. (See: Material Options)

- Paint grade panel skin

- Unfinished wood grain panel with veneer

- Wood grain with wood planks

- FRP galvanized steel

- Aluminum

- Magnesium board

- Marine grade plywood

- MDF metal

- Plastic

- Stainless steel

- Fiberglass

- Ceramic

- Concrete

Please use the work order form in the “How to Buy” section below to obtain a price quote.

WINDOW AND DOOR CUTOFFS:

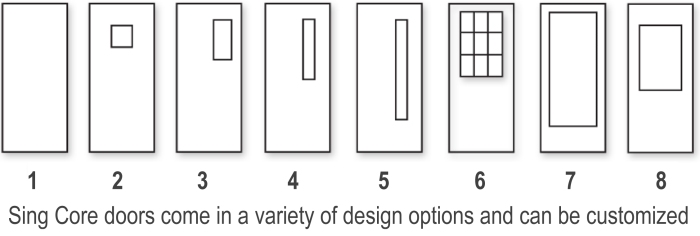

Sing Core provides Sing panels with window and door pre-cut and ready for installation. We will cut 1/8 larger in width and 3/16 inch wider in length to fit your window glass. We build a frame using 1.25 inch solid wood to your specifications. You may create any size or shape of window or door with our simple method just by providing a simple drawing.

MOLDING/TRIM:

Sing Core windows and doors are profile ready for CNC routing. You may add molding or trim to create your own window or door design, otherwise we will provide you with thicker skin — such as 1/4 inch or thicker mdf, hardboard, etc. — for you to carve or profile by CNC machine. With Sing Core windows and doors you can create a true raised-panel door or any design you desire.

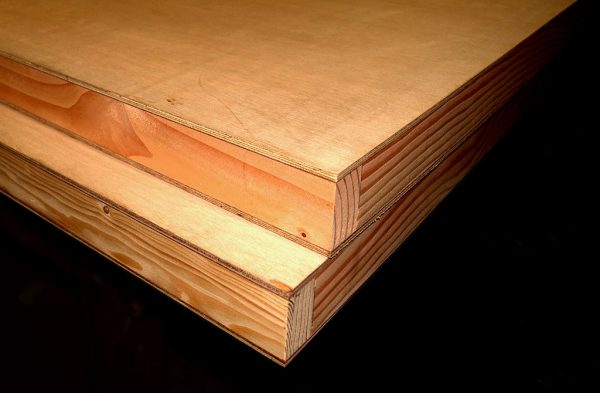

TRIMMED OR UNTRIMMED:

The standard ready-to-ship panel condition is, “untrimmed.” This leaves unfinished exterior edges that may have exposed adhesive and might require being built ½ inch over-sized for trimming at your location. An additional fee will be assessed for trimming and sizing in our factory. All trimmed edges are 1/2 inch over width and 1/2 inch over length. After trimming, your Sing Panel will be 1/2 inch less (4 x 8 will be 47.5 inch x 95.5 inch). Standard solid wood edging with 1.5 inch will be reduced to 1.25 inch after trimming.

SING PANELS FEATURES:

Sing Core Precision:

Sing Panels are + and – .006 inch, so with your CNC machine profile you will have the most amazing detailed door design.

Weight:

Sing Core panels weigh only 4 to 5 pounds per cubic foot.

Compression Strength:

Our 1-inch small grade panels have been tested to reach 660 psi.

Sing Panel Insulation:

Sing panel cores contain urethane form R 6.5 per inch and EPS form 3.5 per inch insulation.

Sound-Deadening:

Sing panels, with proper skin design, will reach stc 56.

Bulletproof and Radiation-Proof Doors:

Sing panels are sold to the major specialty door manufacturers to achieve special demands such as bulletproof, radiation-proof, etc.[/wpex]

Note: Sing Core products are available wholesale only to professional trade professionals, architects, designers, design/build, general contractor, mill work, lumber yard, distributors, door reps and industries.

Best Selling

Our most popular standard product:

Sing Sandwich Core 2 ft x 4 ft x 1.5 in open edge

Sing Sandwich Core 2×4

48 in. x 24 in.

Sing Sandwich 2×4 is a 2 ft x 4 ft pre-built reinforced torsion box substrate that is 1.5 inch thick and features a lightweight plywood surface material that is easily bonded with other products. It’s universal convenient 2 ft x 4 ft size is easy to handle and transport and ships in minimum 4-piece bundle.

It’s a standard Sing Sandwich 4×8 pre-cut into 4 pieces that you can throw in the front seat of your car and turn into anything for endless applications.

The Sing Sandwich Core 2×4 is by far the most versatile Sing product to be released to the world.

Note: Sing Sandwich Core 2×4 is only available in 1.5-inch thick 2 ft x 4 ft size with lightweight plywood facings.

Minimum order $4,000 on 2×4 (48 in. x 24 in. x 1.5 in.), crate optional. For any other alteration, see Sing Panel

Sing Sandwich Panel 4 ft x 8 ft x 1.5 in open edge

Sing Sandwich Panel 4×8

96 in. x 48 in.

The Sing Sandwich 4×8 panel comes in standard 4 ft x 8 ft size panels, with 1/4″ plywood skin:

Minimum order $4,000 on Sing Sandwich 4×8 (96 in. x 48 in. x 1.5 in.). Final price includes shipping and crate.

Standard exterior surface material is lightweight plywood making it easy to apply other surface materials using standard carpenter’s wood glue and clamps.

Sing Sandwich features no solid wood edging, are unfinished and may be edge-banded to hide the visible exposed Sing Core material.

See: Sing Sandwich for more information

See also: How to Close the Edge of Sing Sandwich

The most economical way to access the Sing Core product line it to utilize our basic building material which would be our standard 4 ft. x 8 ft. sandwich panel (like the one[s] featured above). Anything else would require a custom order, please see “Custom Sing Panel” that follows.

Base price does not include shipping, crate and/or handling charges depending on quantity and stock on hand.

Custom Design Your Own Sing Panel

Sing Panel 4 ft x 8 ft x 1.5 inch with embedded solid wood edges

Like our regular custom clients you must know:

- What Size Sing Panel (the length, width & thickness) You Want

- What Exterior Skin (lightweight plywood is the default) You Want

- What Size Solid Wood (standard 1.5 inch) Edges (or specify other material)

- How Many Sing Panels (affects ship & crate cost and quantity may qualify for extra discount)

- Do You Want Untrimmed (default) or Trimmed

- How the Panel Will be Finished (all Sing Panels are unfinished)

Once you have provided the necessary information, they will be able to make sure you get the custom Sing Panel that you desire.

Regularly stocked items have a 1 week turnaround (continental USA) while custom Sing Panels have a 4 to 8 week turnaround. Since all Sing Panels are unfinished, we suggest that you contact a local high quality millwork to do the finish work on your Sing Panels to achieve satisfactory results.

You asked for it; Sing Core gives you what you’re looking for. –>

TRADE SHOW PANEL SPECIAL

Standard Professional Trade Show Panels are 90 inches tall, 2 inches thick with pre-primed HPL, available in the following sizes only:

Panel A: 30 inches wide, cam locks installed

L Connector illustration

Panel B: 24 inches wide, cam locks installed

Panel D: 30 inches wide w/door, cam locks installed

L Corner: 2 inches wide. Attaches two panels together, cam locks installed

T Corner: 2 inches wide. Attaches three panels together, cam locks installed

Special Professional trade show panels (above) are available ala carte; pick and choose what you would like. Pre-design and pick out the components you want from the above list only. Enjoy the savings.

Remember, you can create your more economical DIY trade show booth using standard Sing Sandwich panels available in convenient 4 ft. x 8 ft. size.

CUSTOM ORDERS

Custom Order or purchase Sing Panel please click here —this is only for the trade professional or qualified business-to-business and not available elsewhere at this time.

Sing Core is in the business of providing high-end true flat solutions to the most exquisite architects, designers, millwork, and industrial suppliers in the world. We only provide these services to our commercial accounts.

To obtain a custom order product (anything besides 4×8 or 2×4 Sing Sandwich) see your local trade professional, millwork and/or door company and tell them that you want, “Sing Core inside.” We can work with them to make sure that you get what you want.

As an Industry Professional

As an Industry Professional

Doors that are very tall, wide, and thin are the most difficult to build perfectly flat. Every door is different and has to be treated individually. Sing Core has patented and patent-pending technology to keep the door, no matter the size, flat and compliant with AWI standards.

Doors that are very tall, wide, and thin are the most difficult to build perfectly flat. Every door is different and has to be treated individually. Sing Core has patented and patent-pending technology to keep the door, no matter the size, flat and compliant with AWI standards.