These new, lightweight, high-strength and true flat patented panels are sold by the square foot, just like traditional plywood and sheet goods.

Click Here for Economy Trade Show Panels

40 ft engineered plywood: 2 inch thick weighs in at only 2 lbs. per sq. ft.

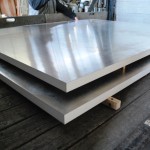

Metal panel: 20 ft. in length x 5 ft. wide x 1 inch thick weighing in at 3.75 lbs per sq. ft. and strong enough to hold 2 people. See pix.

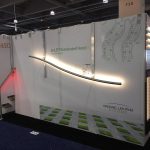

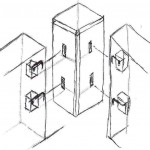

Watch the video for slatwall, track wall, magnetic wall, two story trade show office, floating shelf, cable hanging shelf, etc… You design and we will build the panels for you – this 70 ft. custom trade show system be assembled in less than an hour by 1 man; including 70 ft. of back wall, side walls an enclosed office and storage area.

Now available in affordable lightweight slatwall trade show displays

All Sing Panels are sold like plywood by per square foot.

Fast price quote within 24 hours for custom trade show displays made to your specifications.

Your choice of material options including (but not limited to) HPL, plastic, any type of metal, plastic, plywood, etc… in many colors ready to trim to almost any size and/or add vinyl or metal skin for magnetic sign or hook. Available in almost any size thickness and/or shape.

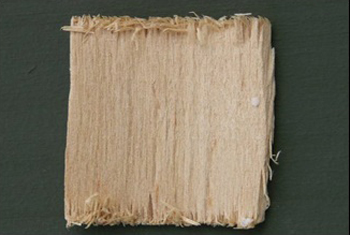

High performance engineered plywood

High performance engineered plywood

See pictures of Sing Panel and Sing Post and Beam supplied to high-end mill works from coast to coast. Click here to see clients list.

How is it possible?

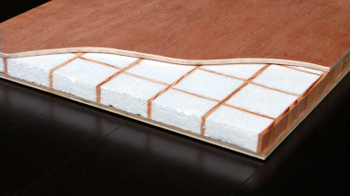

The secret is in our patented natural vertical-wood-grain-torsion-box-filled-with-foam core that allows your team to build huge displays (even 2 stories) without framing.

Wholesale to trade show manufacturers

Click here to see our retail price and compare how much per sq. ft. your cost for the untrimmed patented Sing Panel. You will find out Sing Panel will not only become your top performer in the trade show display industry but reward you with a good profit margin by using Sing Panels.

All Eco-friendly Sing Panels, post and beams are proudly made in the USA.

We can produce hundreds of panels per day by our state of the art technology.

For your viewing please we are providing your with some extra photographic representations of some of the many possibilities of teaming your trade show display company with Sing Core. Feel free to view our Trade Show Display Gallery.

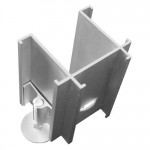

- Insulated office floor panels

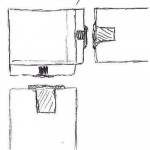

- Sing T in wall assembly

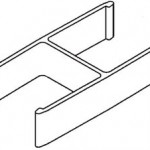

- Lightweight + Strong

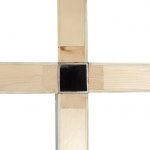

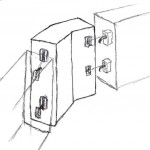

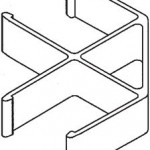

- 4-way Connection

- X Connector