Patented Sing Panels have been used in many industries such as home building, boat building even in the aircraft industry.

Patented Sing Panels have been used in many industries such as home building, boat building even in the aircraft industry.

Making its way to the forefront recently are advancements being recognized by the tiny house community. These tiny house designs are springing up all over the United States (and the world) in the smallest footprints on existing properties, or being transported and towed, like a portable house, small modular home or tiny house on wheels.

Introducing the Sing Tiny House

Don’t Be Framed

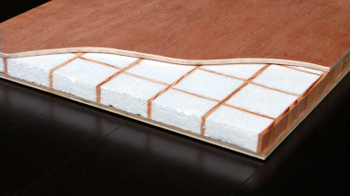

Sing Core products including the Sing Sandwich and Sing Panel have a built-in torsion box structure that delivers superior strength over long spans. With this Eco-friendly building material, the most environmentally conscious affordable home advocate can build a tiny house without the traditional 2×4 or 2×6 frame.

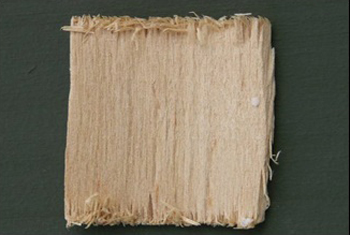

Architecturally, not having to frame your structure yields more precious useable space inside your small home plans. Many Sing Tiny Houses have been built without a frame using 1 ¼” thick Luan skin Sing Sandwich panels. See the structural strength of these 1.25 inch walls in the photo to the right. That is a wall that is 1.25 inches thick compared to the 2×4 wall that is at least 4.5 inches thick, this is wasting 3.25 inches and not as strong as sing Core’s 1.25 inch wall. (Note that the loft beams and roof structure are supported by frameless 1 ¼” thick Luan skin Sing Sandwich panels only. That’s high-strength!)

Architecturally, not having to frame your structure yields more precious useable space inside your small home plans. Many Sing Tiny Houses have been built without a frame using 1 ¼” thick Luan skin Sing Sandwich panels. See the structural strength of these 1.25 inch walls in the photo to the right. That is a wall that is 1.25 inches thick compared to the 2×4 wall that is at least 4.5 inches thick, this is wasting 3.25 inches and not as strong as sing Core’s 1.25 inch wall. (Note that the loft beams and roof structure are supported by frameless 1 ¼” thick Luan skin Sing Sandwich panels only. That’s high-strength!)

Space-age Technology

What makes patented Sing Core products so different from all other building materials is the unique composite nature combining the best technology of an improved wood torsion box design, recycled foam and surface materials that yield the most spectacular results for upscale tiny houses.

Sing Core products out-perform other composite materials (see comparison) used in aerospace and marine applications in terms of lightweight, high strength and Eco-friendly. This new technology can withstand high winds and extreme weather conditions without compromise.

Why Use Sing Core?

#1 – More Useable Space – When building small homes, maximizing each square inch can be huge in performance and enjoyment of your tiny house. (1.25 inch walls vs. 4.5 inch walls).

#2 – High Strength – More rigid and strong than other materials. In fact, Sing Core has been tested at Washington State University at 660 PSI, stronger than steel pound-for-pound.

#2 – High Strength – More rigid and strong than other materials. In fact, Sing Core has been tested at Washington State University at 660 PSI, stronger than steel pound-for-pound.

#3 – Lightweight – Sing Tiny Houses are approximately half the weight of other tiny houses built with traditional building materials. For instance, a Sing Tiny House weighs only 2,600 pounds (easy to tow on trailer) compared to equivalent 5,000 pound tiny house.

#4 – Insulation – Our pre-insulated panels take the time and expense out of insulating your tiny house, and can achieve 6.5 R-values per sq. inch.

#5 – Choices – Customizing options for your tiny house are almost unlimited. You can select any surface material for the interior and/or exterior of each panel including wood, plywood, aluminum, metal, cement board, etc…

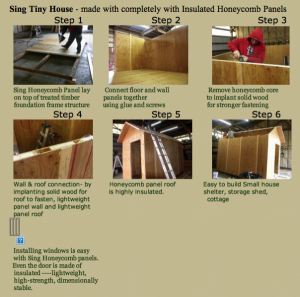

#6 – Easy to Build – We can build a Sing Tiny House complete with floors, walls and roof in three-and-a-half hours. The average, inexperienced do-it-yourselfer might take two days to build. Finish-work can take a couple of weeks, depending on your home design.

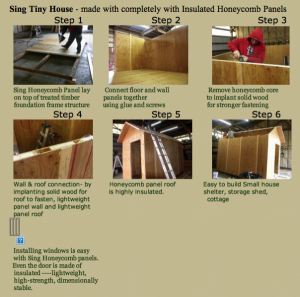

How to Build

If you are not handy, you could find a local wood worker to build your frameless Sing Tiny House, make sure that your contractor is open-minded and willing to take on the challenge of embracing this new building method. If you are willing to learn, most anyone can build a Sing Tiny House.

Connecting Panels

Many methods are available to assemble your panels. Some people chose to use pre-installed cam-locks (especially if the project might need to be disassembled and reassembled), other methods include traditional screws or nails and we like the performance of urethane-glued assembly (which is stronger than other methods).

Here are some photos of a urethane-glued Sing Tiny House work in progress:

Making it Even Easier

Sing Core can help to make the assembly of your tiny house quick and easy by pre-installing window and doors to your specifications in panels for your convenience.

How We Ship

We ship by freight using a shipping broker that finds the best price and route to reach your destination safely and on-time.

Cost to Build a House

Compared to standard plywood, Sing Sandwich and Sing Panels are going to be more expensive, but if you figure in the cost of materials including framing, insulation, plywood, interior and exterior facings plus labor costs in added time and equipment costs, the Sing solution wins out. And that doesn’t even consider all the added benefits of having a Sing Tiny House.

How to Order

Simply count up how many Sing Sandwich or Sing Panels that you need according to your tiny house plans. For instance, an 8×16 tiny house might use 22 4×8 Sing Sandwich panels.

- 4 pieces 4×8 floor

- 12 pieces 4×8 wall

- 6 pieces 4×8 roof

Easy ordering, use our online price quote.

How to Buy

To order Tiny House Small Homes submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

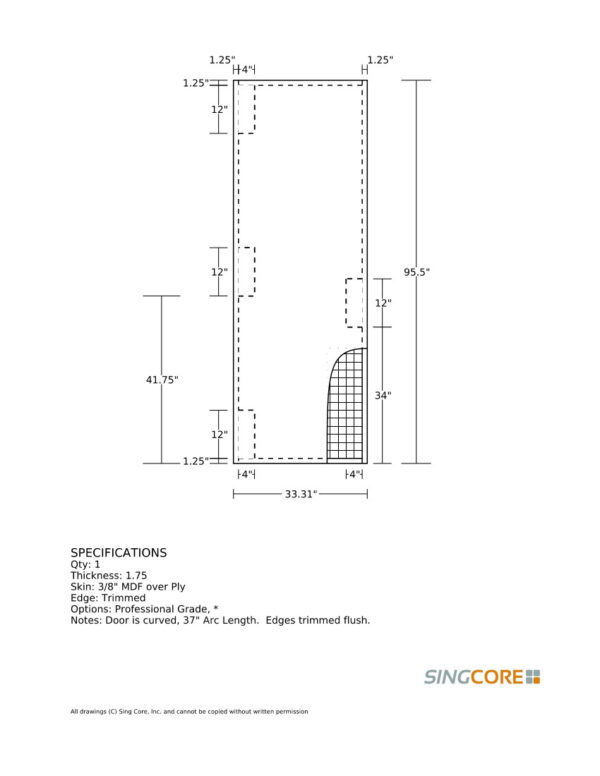

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Tiny House Small Homes are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.